Dowel Hole Tolerance Chart Zero,Quilt Ladder Woodworking Plans Guide,Shank Carbide Router Bit Set 15 Piece By Ryobi - Try Out

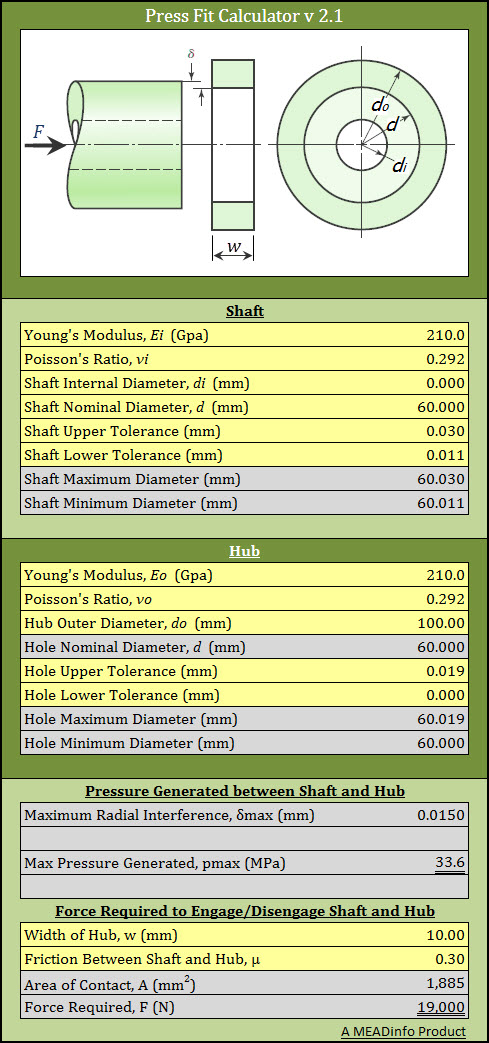

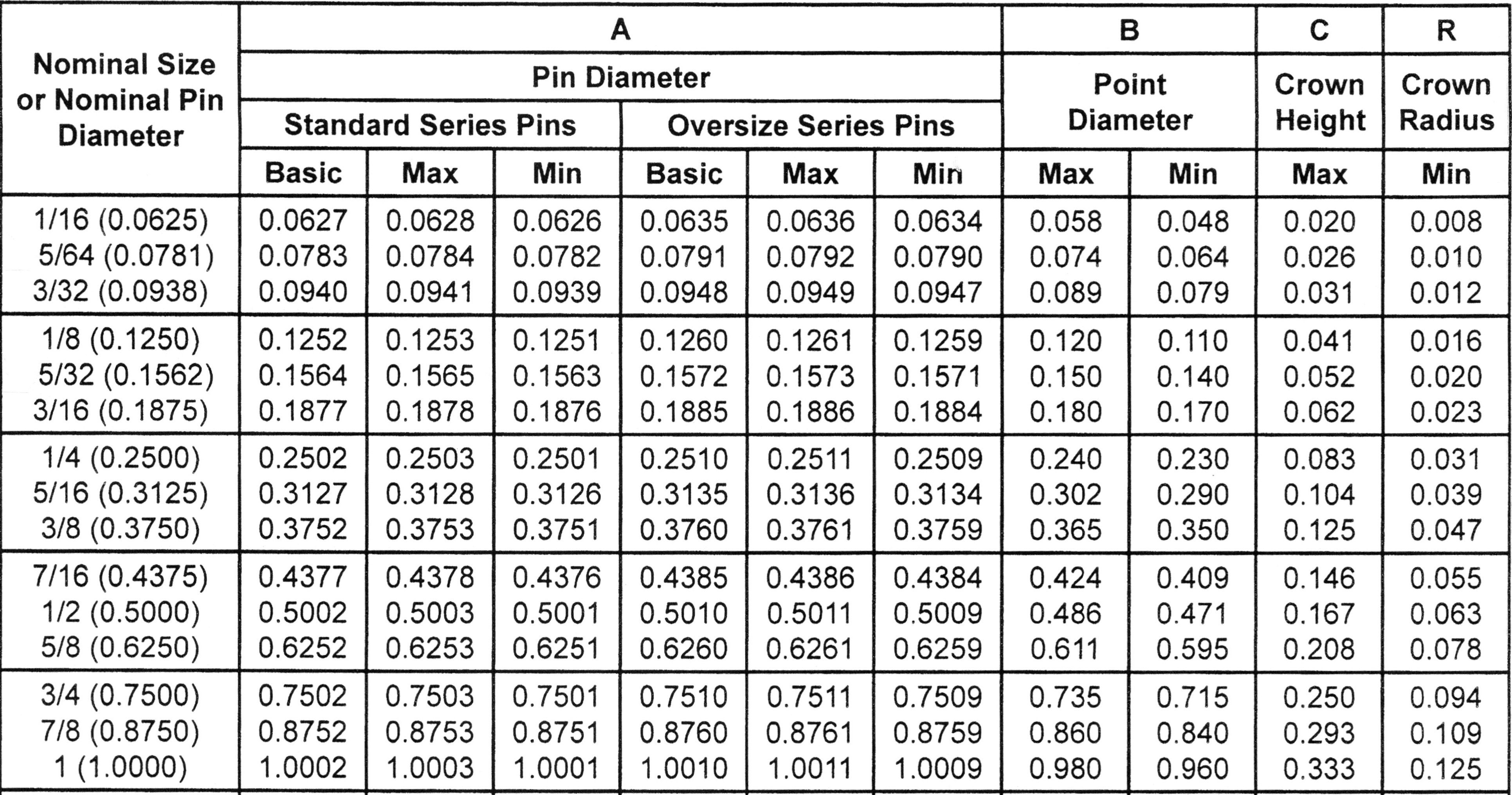

After the mating components are assembled the first time, one should note assembly orientation for repeat assembly of mating dowel pins. It is optimal to design for one configuration assembly fool - proof. See bottom of page for application illustrations. Dowel Pin "D" Diameter. Slip Fit Hole Design.

Membership Register Login. Copyright Notice. Dowel Pin - are stainless steel , , etc.. Application - These fits are for location or alignment applications between two components.

Promoting, selling, recruiting, Dowel Hole Tolerance Chart Table coursework and thesis posting is forbidden. Students Click Here. Related Projects. Hi guys, I'm finally signed up as a member here on eng-tips. Been reading the forums for longer than I can remember, was great help through school and now graduated 1 year ago. So I'd like to discuss about position tolerances of dowel pins. For example, let's say we have Part 1 with two 0. For Part 2, we want to locate accurately and be able to assemble and disassemble by hand; for this we select slip fits on the two dowel pin holes.

Now let's say I dimension my slip fit hole to be. This would require the position tolerance on all dowel pins holes to be. When I released this drawing and the parts were manufacturer, the CNC manager told me that. So I told him I could reduce the clearance and dimension my slip fit dowel pin holes to. So my question: What is a reasonable position tolerance to put on on dowel pins holes?

I found a lot of info on the fits for the diameters, but none on the position tolerance. You need to base it on the function, is this Dowel Hole Tolerance Chart Guide basically a one time assembly or does it have to assemble over and over without broaching out the holes.

If the latter the tolerance will need to be very tight. The numbers you are mentioning are very close to what we used in the machine tool industry as standard. In the shop I am in now, they whine and cry at twice the tolerance we used to require as standard in machine tools. I agree with fsincox, the function should dictate the tolerance.

And if the resultant tolerance is tighter than practical you can look for alternate solutions, which could be: 1. However, if you were to perform a worst case tolerance stack and revise the prints to show these it would raise some eyebrows. As to the possible values for tolerances I would not hesitate to go with POS dia. Also, you will need to apply a projected tolerance value to the pin holes equal to the protruding height of the installed pin. Are you using a round and relieved pin combination or 2 straight pins?

In this case, say function is locating, with the requirement of assembly and disassembling by hand for maintenance. Say the parts will be assembled and disassembled say once a month.

In this case, the dowel pins are just 2 standard straight pins. It was actually recommended to me to use that practise. It was suggested that I put. I raise the point that this would require a position tolerance of. I like to know that the parts I design will fit together without requiring fiddling at assembly.

So the parts that I described above, with the two slip fit dowel pins holes of. You definitely 'feel' the clearance of. This suggests that I should follow his advise, and tighten the fit on the dowel pin slip fit holes.

As a result, this would also tighten the fit on the position tolerance. Without a reference frame as to 'how easy' it is to hold a position tolerance of. Here's another similar question: what position tolerance on the diameter of dowel pin holes do you use in the case where the dowel pins are press fitted into both parts?

I think generally, when using pins, the function is locating. The key to me is: is it essentially a one time basically, permanent assembly or must it reassemble without a significant degradation over time the pins broach the holes. We had both in machine tool. Gear cases used dowel pins that were creating essentially permanent assemblies vary rarely disassembled the parts could be driven together at assembly. We made transfer lines for all of the big car companies.

Every single engine block sees every single machining station and was located on a face primary and 2 dowels one round and one relieved. You do not want the location to get sloppier as it goes down the line so the tolerances are tight and must they be.

One dowel pin engages an accurate, round clearance hole. The other dowel pin engages a slot that lines up with the first Dowel Hole Tolerances hole. I can't add much to the tolerance arguement.

But this stood out: "CNC manager told me that.

|

Wood Carving Machine Bunnings Best Usa Bench Vise Design |

KABIRDEN_MEKTUB

06.07.2021 at 15:19:37

BubsY

06.07.2021 at 21:32:14

mamedos

06.07.2021 at 15:36:31