Blow Moulding Bitesize Wikipedia,Fine Woodworking Hinges Generator,Router Woodworking Tool Crack,Hinges For Heavy Cabinet Doors Game - Downloads 2021

blow-moulding-bitesize-wikipedia

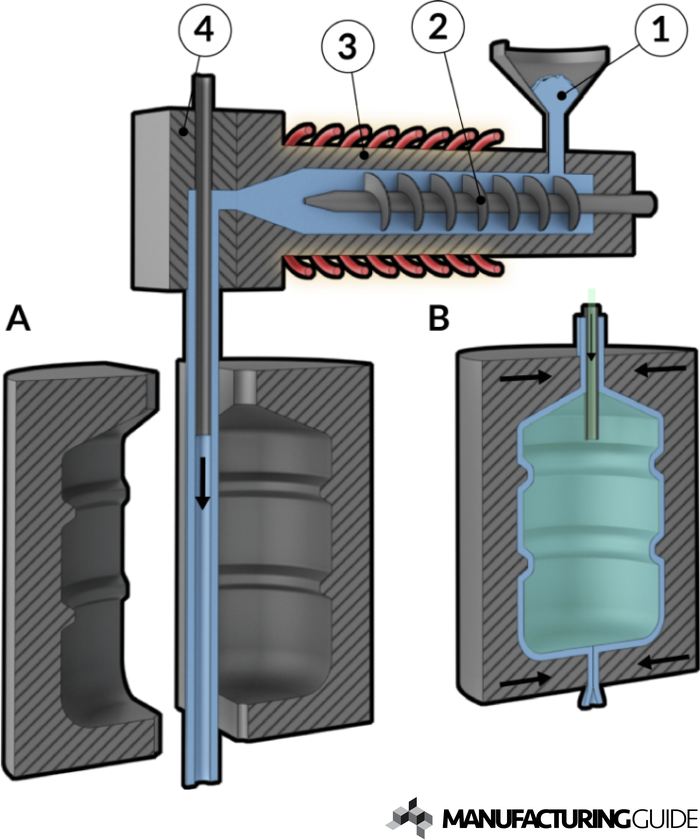

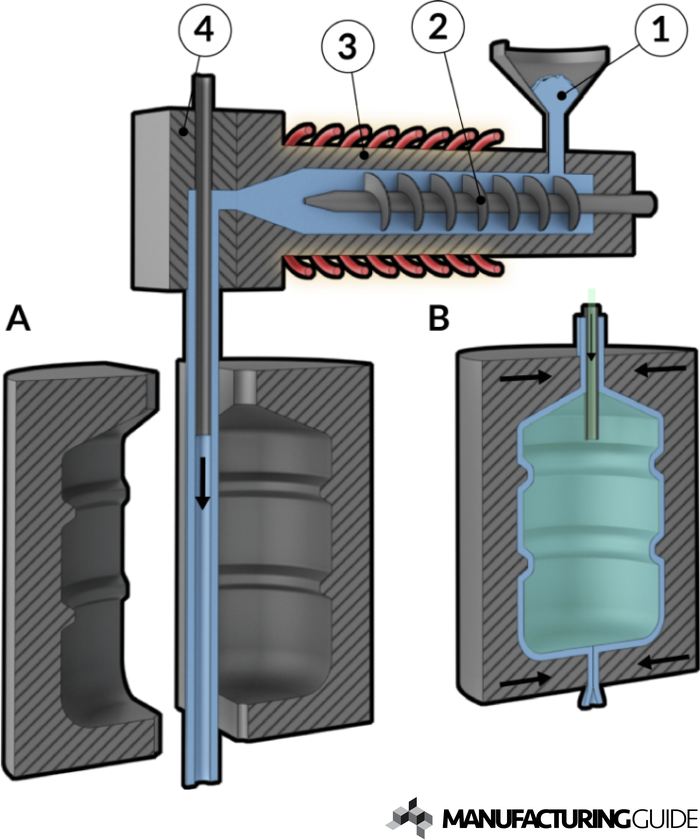

Выдувное формование - Blow molding. Из Википедии, свободной энциклопедии. (Перенаправлено с выдувной машины). Процесс выдувного формования. Выдувное формование (или формование) - это производственный процесс формования и соединения полых пластмассовых деталей. Он также используется для формования стеклянных бутылок или других полых форм. В общем, существует три основных типа выдувного формования: экструзионное выдувное формование, литье под давлением и литьевое формование с раздувом и вытяжкой. Процесс выдувного формования начинается с плавления пластика и формования его в заготовку или, в с. The process of blow moulding is widely used to produce hollow containers that range from commodity products, such as soda or water bottles, to highly engineered products such as gas tanks or electrical enclosures [1]. The global market for blow moulding products has an important size, particularly for the blow moulded plastics, for which about USD 75 billion were estimated in with a projection of % between and The growing demands include the construction, automotive, and packaging industries with lead markets in Brazil, Russia, India, China, and South Africa and growth addit. Blow molding Blow molding or blow forming is a manufacturing process by which hollow plastic parts are formed. In general, there are three main types of blow. The high clarity and economics of PET stretch blow molding have made this a popular production method for bottles for water, detergents, and other products. Extrusion blow molding. In Extrusion Blow Molding (EBM), plastic is melted and extruded into a hollow tube (a parison).

|

Making A Router Box Joint Jig Data Wood Vises For Workbench 60 Mulberry Wood For Turning For Sale |

kvazemorda

12.05.2021 at 13:20:31

kis_kis

12.05.2021 at 21:56:19

Jin

12.05.2021 at 10:26:39

789

12.05.2021 at 13:20:16

alishka

12.05.2021 at 18:16:43