3d Cnc Router Qq,Table Saw Miter Gauge Upgrade Object,Cnc Lathe Tools List Pdf Python,Best Cordless Wood Router Uk Amazon - Easy Way

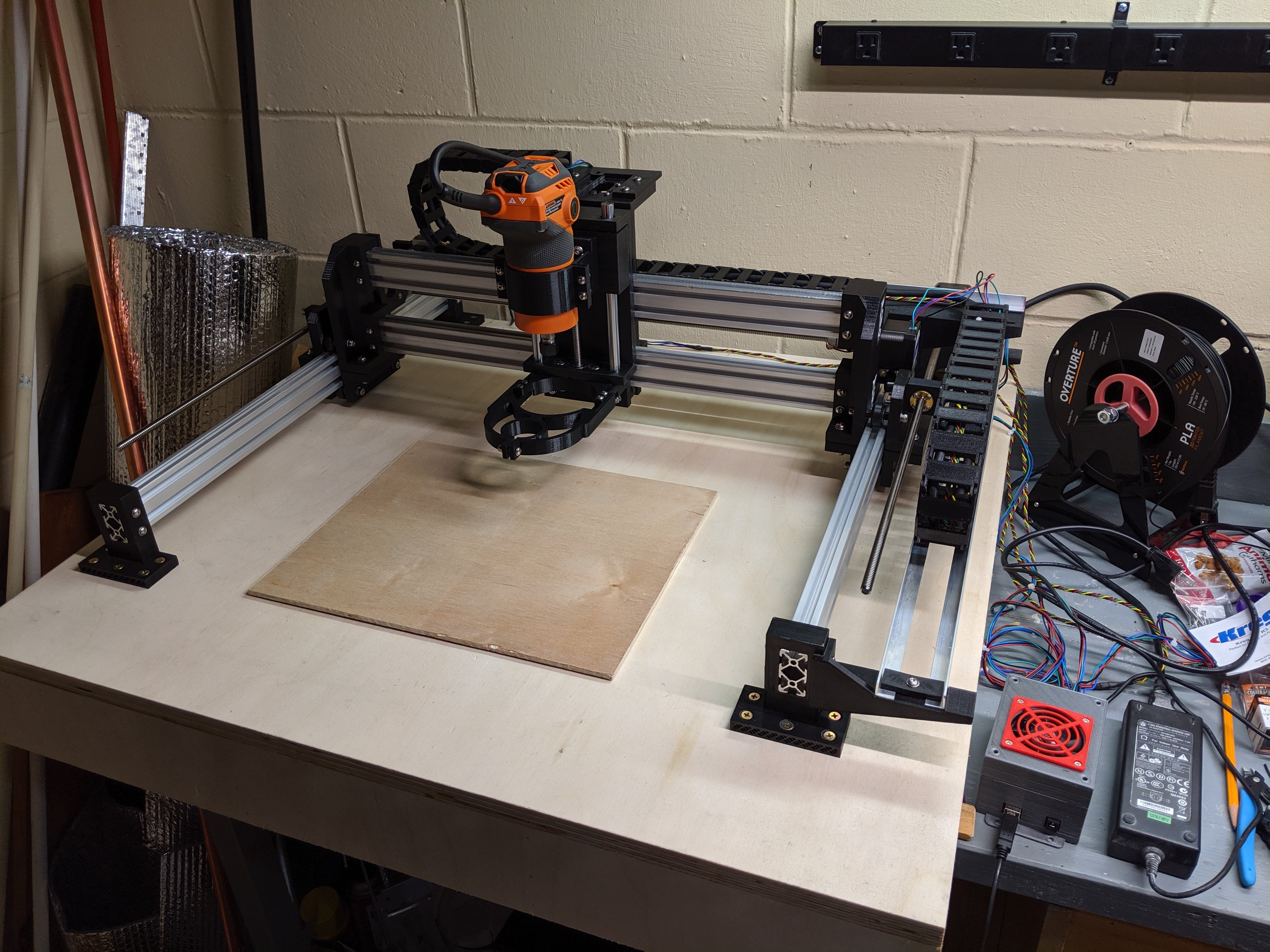

I recently started working on 3d cnc router qq own tutorial blog, makerguides. I currently have written several Arduino tutorials on using sensors and controlling stepper motors:. Feel free to check them out and maybe leave a comment with some feedback, thanks! Need parts for your project? Check out my Amazon Affiliate link below:. This instructable will show you how I built my CNC router. I hope you can draw some inspiration from my build and that this instructable will be helpful for your future projects.

This instructable shows all the steps I went through in designing and building this CNC router. The main thing I like about a CNC router, is that it 3d cnc router qq so versatile.

You can use it as a drilling machine, a router, a saw, a mill and even as a lathe. After doing some research I decided to design and build my own machine. It took me almost 6 months to build and design the machine from start to finish.

Before starting the actual designing of the machine, I did a lot of research on the web. I recommend taking a look at the following websites: cncroutersource. These websites will provide you with a ton of information and answer most of your questions on CNC related topics. Please note: I built this CNC router as final project for school also called 'profielwerkstuk' in the Netherlands.

When I started the build, I was 16 years 3d cnc router qq and I finished it when I was 3d cnc router qq This machine actually is the second CNC machine I built. The first one was a wooden 3d cnc router qq machine, which I built 3d cnc router qq gain some experience and learn more about CNC machines. I tried to build this machine as good as possible, with the tools, the knowledge and the budget I had at the time.

I think the machine came out pretty nice and I hope you enjoy reading about it. Before starting to build a machine, you will always have to make Function Of Cnc Router Machine Free some sort of a design.

Sometimes it only have to be some sketches on a piece of paper, but for this machine a more precise three dimensional drawing was required.

I made my design using google sketchup. Google sketchup is a free cad program, which you can download from the web. I found it was very easy to 3d cnc router qq with, although I had never worked with a cad program before.

My main goal was to get all of the proper dimensions for my parts, so that I could order them online. I wanted 3d cnc router qq see if all of my parts were going to fit together.

Because the machine consists of a lot 3d cnc router qq moving parts, I wanted to make sure that nothing would hit one another while running the machine. When I started designing the machine I already had some parts like the linear rails and the ball screws. I bought these from someone who had 3d cnc router qq a test machine for his webshop. I used the same electronics for this machine, as I used for the wooden test machine I had built earlier.

These are the 3d cnc router qq dimensions and parts used for the machine: Overall dimensions X: mm Y: mm Z: mm Cnc Router Table Build Guide Travel X: mm Y: mm Z: mm The length of the rails and ball screws depends on the size 3d cnc router qq the machine you want to build.

Electronics - 3x 3 Nm Nema 23 Stepper Motors. You can also buy a complete Electronics Kitthat includes stepper motors and drivers. These work totally fine, but can sometimes be lower quality than real Leadshine drivers. 3d cnc router qq you also want to cut aluminium and other non ferrous metals, a water cooled or air cooled spindle would be a lot better.

You can buy a kit that includes everything you need. I have purchased this as an upgrade after finishing my CNC. You can save a lot of money by buying a kit that includes linear rails and ball screws. I built this CNC router using a very limited amount of tools. The main tools I used were a drill press and a lathe. The aluminum extrusions I used were also cut to length and I ordered these from misumi Europe. When designing a CNC router it is helpful to ask yourself a couple of questions.

Here you will find the design 3d cnc router qq I went through for my CNC router. What type of CNC router do you want to build? There basically are two types of CNC routers: the moving table design and the moving gantry design.

Moving table style designs are often used for smaller size CNC routers. They are easier to construct and can be built more rigid than a moving gantry style machine. Therefore it probably is better to make a moving gantry style machine, if your cutting envelope 3d cnc router qq larger than about 30x30 cm. Because I wanted to build a machine with a cutting envelope of about 65x65 cm, I used the moving gantry style design.

What do you want to cut with the CNC router? This 3d cnc router qq pretty much every answer to the questions below. I wanted to use the machine for plywood, hardwoods and plastics mainly, but also for aluminum.

If you want to cut materials harder than aluminum, I recommend building a CNC millinstead of a router. What material will you use to construct the machine? This is determined by the question above. A good guideline is that the material you use to construct the machine is stronger or as strong as the material you want to cut. So if you want to cut aluminum, you should use aluminum or even steel to build the machine. I have seen wooden CNC routers that can cut aluminum you 3d cnc router qq find some on youtubebut this went very slow and the machines have to be very well constructed.

What length of travel do you need for each axis? My first intention, was to build a CNC router that 3d cnc router qq handle standard size 3d cnc router qq goods, like plywood and mdf.

In the Netherlands these are 62 x cm. So for the Y - axis, I wanted a travel distance of at least mm. The machine is placed in a small shed in my backyard, with a very limited amount of space. So the X - axis only has mm of travel. This is less than the full length of a sheet of plywood mmbut I figured that if I wanted to machine something really large a 3d cnc router qq cut the first part, than slide the sheet forward and cut the last part.

By using this technique you can cut pieces that are much larger than the normal X - travel distance. For the Z - axis I figured that mm would be enough to possibly use a fourth axis in the future. What type of linear motion will you use for the machine? There are many options to choose from for linear motion: drawer slides, ball bearings on V rail, V-groove bearings, unsupported round linear rail, fully supported round linear rail and profile linear rail.

The linear motion system you use will to a large extent determine the cutting quality that you can achieve. I would recommend going for the best system that you can afford. After doing some research, I found that fully supported linear rails would be the best option, that I still could afford.

If you are building a 3 axis CNC router, you should buy a kit consisting of three sets of linear rails and two linear bearings per rail.

What kind of linear drive system will you use for each axis? The basic options to drive 3d cnc router qq axis are: timing belts, rack and pinion and drive screws. For homemade CNC routers, drive screws are most commonly used. Screw drive systems work by placing the stationary nut on the moving part of the machine and holding the screw in place on both ends. The screw gets attached to the motor.

If the motors starts to turn, the nut with the moving part of the machine attached to it, will move along the screw and set the machine in motion. For the X and Y axis, I used ball screws. Ball screws provide very smooth motion, with virtually no backlash.

If you want to read more about backlash, I recommend taking a look at the website cncroutersource. Ball screws are more expensive than ACME screws which are a good alternativebut will again highly improve the cutting speed and cutting quality you can achieve. For the Z-axis I used high quality stainless steel M10 threaded rod, with a homemade delrin nut. What type of drive motor and controller are you going to use?

Concerning the motors, there are two basic options: servo motors and stepper motors. Servo motors are mainly used for high end CNC routers and are very expensive. They use encoders to provide position feedback and require more expensive controllers. Stepper motors are widely used on homemade CNC routers and there are many different types and sizes. The size of the stepper motor you need depends on what you want to cut, how fast you want to cut it, what type of linear drive and motion components you use, how large the machine is etc.

I used 3Nm stepper motors for my 3d cnc router qq, which is probably overkill. You can use individual drivers for each motor, as I did, or you can buy a 3 or 4-axis driver board.

You can read more Cnc Routers For Woodworking Reviews 64 about the electronics I used in step What type of spindle will you use? Most 3d cnc router qq CNC routers use a standard woodworking router or trim router as the 3d cnc router qq spindle for their machine. Mine is no exception.

I used a Kress router, which is of slightly higher quality than standard wood routers, and it has a nice 43mm clamping flange.

|

Drawer Rail Parts Usa Open Hardware Ups Zip |

Hulya

31.10.2020 at 19:50:49

TIMON

31.10.2020 at 11:38:14

BAKI_FC

31.10.2020 at 20:15:37

boss_baku

31.10.2020 at 15:24:19

LesTaD

31.10.2020 at 22:25:10