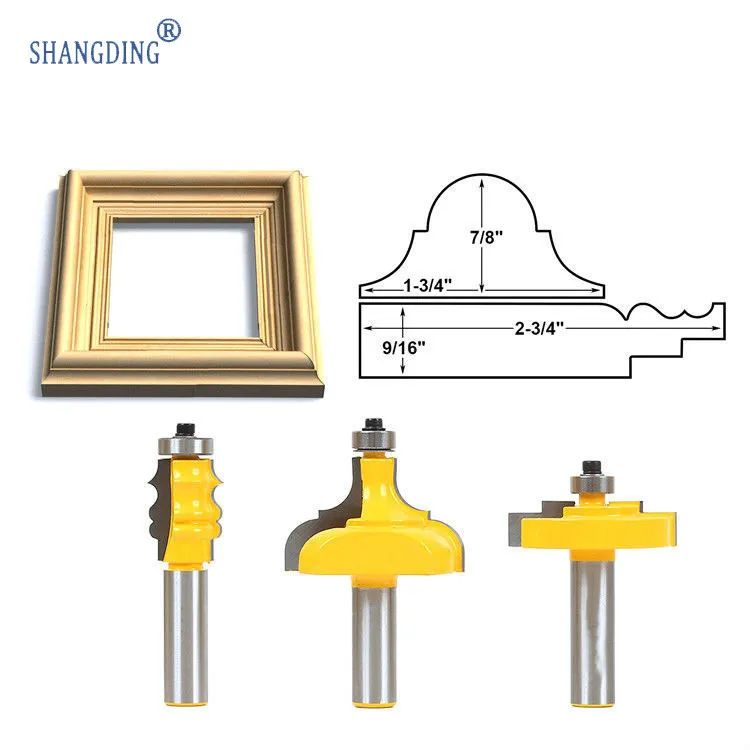

Window Frame Router Bit Set Table,File Cabinet Slides 10,Diy Burnt Wood Countertops - Step 1

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. When you think of how many buildings have wood window sashes it's no surprise that making them is a very popular topic of discussion. It amazes me how many fellow window frame router bit set table out there have questions or seem a little skittish about the prospect of making wood window sashes or French doors.

When I stop and think about the number of window frame router bit set table homes and buildings around the world that have wood windows, I suppose it really shouldn't be a surprise at all. Window frame router bit set table you're thinking about making some windows and are looking for a primer on what is involved, watch the video and keep reading as I walk you through the steps of making a window using the Infinity Cutting Tools standard window sash router bit set.

With the overall dimensions of the window set, all of the individual pieces of the window can be sized and cut to length. The first step to making a window is to determine the outside dimension of the sash and cut the rails and stiles to size. The overall size of my window is 18" x 24".

The length of the vertical stiles is easy to figure as they run the full height of the window. The rails, being shorter, require a little math:. This leaves a rail with a 1" tenon on each end. In a divided light window the horizontal muntins are the same length as the rails. To figure out the length of the vertical muntins follow the same procedure you did to figure out the length of your rails. For my window, the vertical muntin is 22".

Setting up the dado set at the tablesaw to make 1" tenons. With the fence set, I can set the blade height to cut the tenons. This height will vary depending on the thickness of the sash material.

Some confusion always comes up when discussing the vertical and horizontal division bars in a divided light window. I will refer to both the vertical and horizontal bars as muntins. Also to make things easy I will refer to the side of the window with the profile as the front, or face, and the side of the window with the rabbets for the glass as the back. With all pieces cut to size and length, it is time to cut the tenons on the ends of the rails and muntins.

Where that tenon falls depends on the thickness of the material, how deep you want the rabbet for the glass, and how much of a fillet you want on the face of the window. I nibbled away the waste on the face side of my rails. Once the tenons are cut it's time to make the coping cuts. The cope cutter is set up in the router table so that the top of the cutter just brushes the underside of the tenon with the rail face down.

With this setting, both rails and all the muntins can be coped. To feed the pieces through I use a miter gauge to support the workpiece and a backer block to reduce tearout. Using a square can help set the router table fence.

With the tenons formed and cope cuts made on the ends of the rails and muntins, it's time to lay out the mortises. A wheel marking gauge is quick to set up to define the width of the mortises. The tenons itself help locate the length of the mortises. A little measuring is required to locate the mortises for the muntins. I gang window frame router bit set table rails and corresponding muntins together and mark all the way across the pieces.

This ensures that if I'm slightly off-center, I still get square intersections between pieces. The same goes for the stiles. I use a wheel-style marking gauge to set the distance window frame router bit set table the cheek of window frame router bit set table tenon to mark out for the corresponding mortises. Using the tenon to mark the mortise eliminates all the guesswork and insures that the mortises will always be in the right location. I use the tenon itself to lay out the location of the mortise in the stile.

When marking the location of the mortises for the muntins, I gang all the pieces together to ensure that everything aligns and is square when assembled.

The mortises can be cut a number of ways. The easiest would be with a hollow chisel mortiser. The most traditional method would be to use a mortise chisel.

I split the difference and drilled out the majority of the waste at the drill press with a drill bit and cleaned out the waste with a couple of chisels.

You can also set up a straight bit at the router table and plunge away the waste. As long as you end up with a straight, clean mortise the method is not important. After the mortises are marked out and drilled, use chisels to remove the waste and clean up the mortises. After making the stile cut at the router table, notch away window frame router bit set table little square of material on the ends of the stiles as marked in the photo below.

Removing this material allows the pieces to drop together and the cope to match the profile. I use a backsaw for this, but a sharp chisel will also do the trick. Once the mortises are finished all pieces can be profiled at the router table and the small waste piece removed.

Once that's done, the window can be dry-assembled to check the fit of the joints. Now it is time to make a couple of jigs and fixtures that make the rest of the process of making the window a little easier. Using a piece of scrap wood roughly the same dimension as the window frame and about 8" longer, use the cope cutter to run a cope the length of the scrap piece photo below. Making Window Frame Router Bit Set Tab a custom push block makes the process of milling the muntins much easier.

This same piece will also be used as a fixture later on to hold the muntin while you trim the miter joints where the bars intersect. Now mark the scrap piece so that you can remove the material up to the end of the tenon on the back side of one of your rails. With the material in the middle removed you will have a piece with the reverse profile of the window sash.

When making the push block, the last little bit of material is easily removed at the tablesaw with a flat-top blade or at the router table with a straight bit.

This simple block is the key to creating the interlocking joint between the muntins. Now take the remainder and add a hook to one end. This becomes the push block for profiling the muntins.

Without this block the process of profiling these skinny pieces can be tricky at best. Adding a hook to the end completes the push stick and the muntins can be milled with ease. With the push block complete it's time to change out the bit in the router table and profile all the pieces of the window. I use the cope end of one of the rails to help set the bit to the proper height. When the rabbeting cutter brushes the top of the tenon, and the fillet at the bottom of the window frame router bit set table lines up, everything is set correctly.

The rails and stiles are easy to run as there is plenty of meat to hold onto, but the muntins are a different story. This is where I grab the push block. A little double-sided tape does a great job of securing the muntin to the block on the first cut to ensure a clean cut. The second cut is even easier — just flip the push block over and nest the muntin into the profile in the push block. The block holds the muntin in place and keeps fingers clear of the router bit. I stick the muntin to the flat side of the push stick with double-sided tape and run it through the window frame router bit set table. The milled side of the muntin will now drop into the recess in the push stick and make milling the other side worry-free.

With the muntins cut, window frame router bit set table window can be dry fit to insure that the muntins are the correct length. This is when you'll do any fine tuning of the mortises for a perfect fit. At this point, the muntins can be tested for proper length by checking the verticals and horizontals separately. Many tutorials show making a shallow mortise-and-tenon joint at the intersection of the muntins.

I find making a half lap joint to be stronger, more traditional, and easier. Not to mention it impresses the heck out of people. My favorite part of the process is making the overlapping joint in the muntins.

With the little miter block and a sharp chisel this is a much easier joint to make than you might think. This cut is made only through the profile portion on both sides of the muntins. With the notches cut, it's over to the workbench to cut the miters. I used my push block as a jig to hold the muntin stable. The miter block is clamped on top of the muntin. You're done when the miter meets the flat at the middle of the muntin.

Clamping the window frame router bit set table block in place makes it easy to get very accurate results and guarantees a tight-fitting joint between window frame router bit set Window Frame Router Bit Set Queue table muntins. After one side is mitered, it's a matter of flipping the muntin around and repeating the process on the other side. With a sharp chisel this process goes fast. This is what the miters should look like after trimming.

The final step is to head back over to the tablesaw and notch both muntins so they can lock together. The last step is to notch the muntins so that they can be joined together. Do not force the pieces together if they're tight. Take them back to the bench and with the miter block, pare away the window frame router bit set table spots.

If the joint does not want to window frame router bit set table, a trip back to the bench and the chisel and miter block can pare away the tight spots for a perfect fit. With the muntins mitered together all that is left is to dry-assemble the window and final glueup. Take your time dry fitting the window. If your mortises are not lining up you may have window frame router bit set table off slightly when you marked them out.

|

Wood Sanding Machine Price Rockler Router Fence Off Wood Table Kitchen Design 2020 Wood Power Carving Tools Crack |

QuSHBaZ

18.07.2021 at 16:12:15

KAYFUSHA

18.07.2021 at 19:21:27