Using Japanese Hand Saws,Jet Plane Training Office,Powermatic Planer Parts Code - New On 2021

We offer them here as a set at a savings. One side of the blade is filed with fine teeth for cutting across the grain. The other is coarser for ripping along the grain. The Special Japanese Dovetail Dozuki excels as a stiff-backed joint cutting saw.

The blade is 7" long with 25 tpi. The Flush Cutting Saw blade 6" long, 24 tpi will cut off flush pegs, through-tenons, and other exposed waste parts of joints absolutely flush. An extremely flexible blade with no set, it will not mark the adjacent surface. Tool length is 10".

Today I teach Japanese woodworking techniques and take on custom woodworking projects in my Brooklyn studio, but my first exposure to Japanese-style woodworking was entirely accidental. When I began to learn woodworking in a cabinet shop, we worked primarily with power tools. I purchased my first saw and the pleasure grew—motivating me to undertake a formal apprenticeship with a Japanese woodworking master.

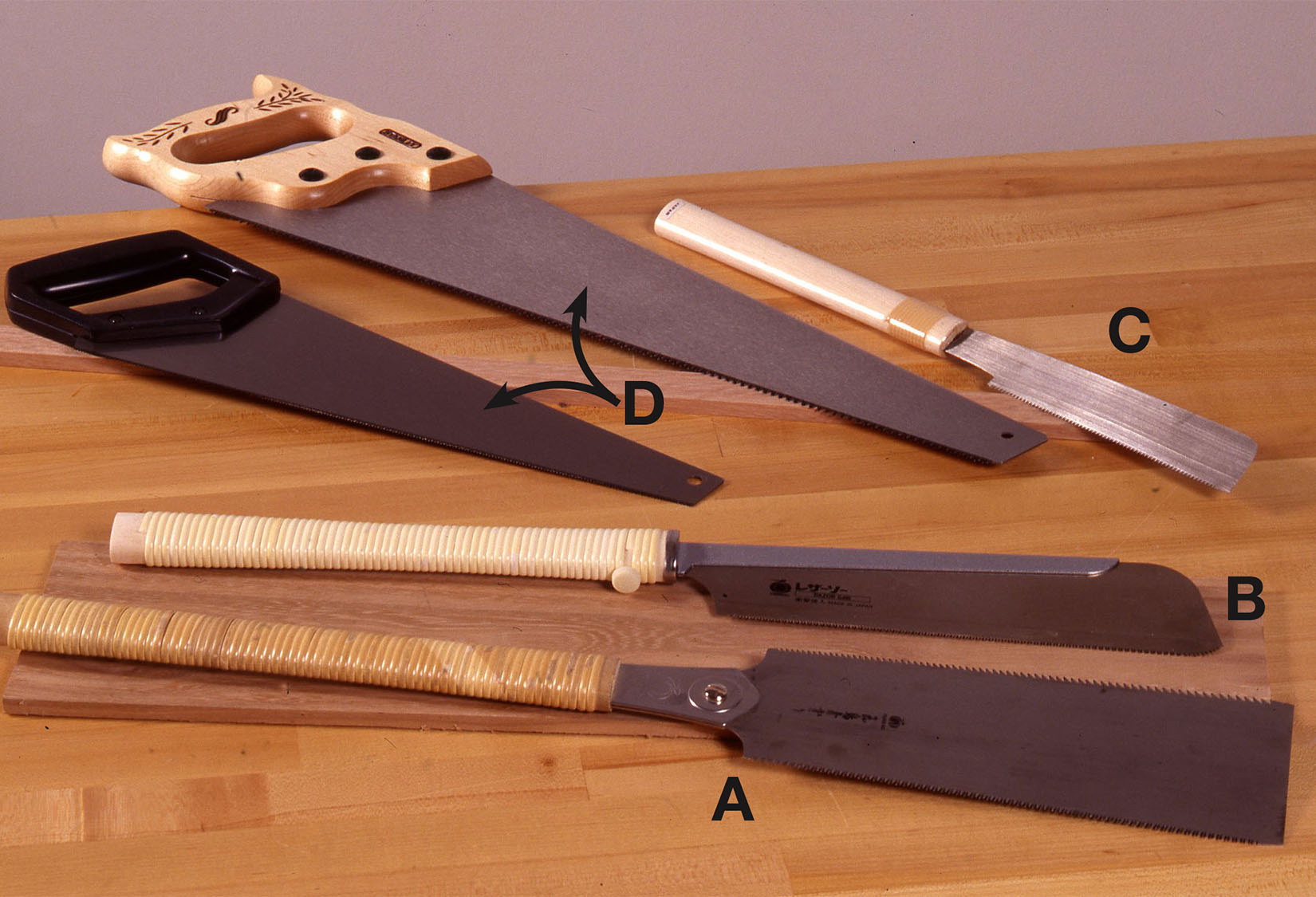

Versatile cutting capability. Japanese saws come in different styles, based on the type of cutting that needs to be done. The three basic types shown here can handle a wide range of cutting assignments. Magnified views show that ripping teeth on pull saws are similar to those on Western-style saws.

But crosscutting teeth on Japanese saws have a long, knife-like form that allows them to cut quickly, smoothly and with less effort. The pros and cons of pull saws have a great deal to do with their thinner blades and with the way that crosscutting blades are sharpened see photos below. One blade, two sets of teeth.

The workhorse of Japanese saws, the ryoba is easy to identify because it has two sets of teeth—one for ripping and one for crosscutting. In general, shorter saws have finer teeth, enabling you to do more exacting work. The teeth are fine enough for very precise cutting—the next-best thing to a dozuki saw for joinery work.

When just starting to use a ryoba saw, it may seem difficult to make a straight cut with such a flexible blade. The secret is to plan your cut so that the kerf you initially make can guide the blade as you finish the cut.

Start cutting at the top corner of the workpiece, and maintain a diagonal stroke that follows the layout lines on adjacent surfaces. Cut all the way to the top shoulder and bottom corner.

Then switch to a vertical stroke. The existing kerf can guide the blade as you complete the cut. Start the cut at the top corner, and maintain your cutting angle as you saw.

When the kerf extends nearly all the way across the top of the workpiece, change your cutting position so the top kerf can help guide your cut into the near side of the workpiece. Cheeks, then shoulders. Then I switch to a dozuki shown here to make the shoulder cuts. The dozuki is just the ticket. Like a Western backsaw, it has a thick steel spine that keeps the blade rigid as you cut. But unlike a Western backsaw, a dozuki cuts on the pull stroke, and it has a much thinner blade that excels at precise cutting.

They cost less, but can still handle most of the joinery work required for furniture construction. For many woodworkers, the answer is the kataba yokobiki. The kataba eliminates this problem.

Quick View. Add to Cart. Most dozuki saws have replaceable blades Photo 5. A second blade usually costs about half as much as the saw itself. Each replacement blade is specifically made to fit only one brand of saw. Reserve the fresh blade for the cuts that really matter. Dozuki saws have three different ranges of teeth size. Most saws have 22 to 27 teeth per inch tpi. Saws with large teeth have 13 to 18 tpi. Getting started on the first cut, without bouncing, takes some practice.

A few dozuki saws have incredibly small teeth 32 tpi. Our favorite is a 6-in. Dozuki saws have blades of two different lengths: short 6 to 8 in. Two blades of different lengths by the same maker usually have the same number of teeth per inch. A saw with a long blade is best for most work.

You can take a long stroke and cut fairly deep each time you pull the saw. Short blades are best suited for small work or shallow cuts, when fewer strokes are needed. Click any image to view a larger version. It cuts on the pull stroke. An English-style backsaw, of course, is just the opposite; it cuts on the push stroke. The dozuki saw blade is very thin and makes a much narrower kerf.

The less wood you remove, the easier it is to guide the saw. Cutting small parts is safe and easy with a dozuki saw. Dozukis are designed to make splinter-free crosscuts that are as smooth as glass. Make your own miter box to guide the cut. The teeth on most dozuki saws are designed for crosscutting.

They have small, angled tips that score the wood like the blade of a knife. These teeth do a fine job with short rip cuts, such as dovetails, but some specialized dozuki saws have teeth designed primarily for ripping. Most dozuki saws have replaceable blades. When your blade gets dull or damaged, just drop in another one. This blade rotates out of its stiffening spine when you tap it against a block of wood.

Yup, this saw blade is history! I pulled too hard, and when the blade came out of the cut, I tried to push it right back in. Dozuki saws take some getting used to. For the rest of us, forget everything you know about saws. Dozukis are that different. First, you have to get used to cutting on the pull stroke. Wear a blindfold. Just feel the saw cut.

|

Stanley 71 Router Plane Replacement Blades Out Woodworking Furniture Plans 201 Soft Close Drawer Slides Repair Kit |

Anonim

27.10.2020 at 16:16:15

U_of_T

27.10.2020 at 10:13:48

SuNNy_BoY

27.10.2020 at 11:52:43

97

27.10.2020 at 19:45:48

ADMIRAL

27.10.2020 at 14:12:49