Sharpening Grinder Wheel 900,Best Bench Players Of All Time 4g,Powertec Dust Collector Fittings Journal - 2021 Feature

Our article is filled with the right information just to help you sharpen your tools on a bench grinder. When you have a very dull or heavily damaged tools, skip the file Grinding Wheels For Bench Grinders Guitar and other hand tool sharpening options and head straight for your bench grinder.

The bench grinder should handle any tool sharpening tasks with ease and save you Sharpening Grinder Wheel 3d a lot of time. Here are some tips to help you sharpen your old tools on a bench grinder :. One tip that may help you when you go to sharpening your turning tools is that using a grinder is almost the same as using a lathe.

The techniques are almost exactly alike. After that, you will find that sharpening your turning tools involve a lot of accessories and can get quite detailed. There are smaller gardening tools that you need to keep sharp if you want your garden looking its best. The smaller tools are easy to handle and a bench grinder is a perfect tool for the job.

It certainly beats using a file and a vise. Here are 4 tips to help you sharpen your smaller garden tools:. You can sharpen larger garden tools on a bench grinder. Hand sharpening is always an option but if you do not have the time or the patience, a bench grinder does the trick as well.

The axe or hatchet will be sharpened in the same manner. It is not too difficult to do, the only trick you may have is how to hold the handle as you grind. The technique to sharpening an axe or a hatchet is similar to the one used to sharpen a lawnmower blade.

When sharpening tools on a bench grinder, there are always safety tips and tricks you can do to make sure you do not hurt yourself , those nearby or your equipment. Here are a few of those safety tricks:. Using a bench grinder to sharpen your tools is a smart move to make. It will help save you money and the bench grinder moves a lot quicker than hand sharpening.

The main attitude to have is patience. It will require several passes to get the right edge to your tools so take your time.

There is no rush. If you get the tool sharpening task right, then you can get your other tasks done correctly and probably a lot faster. Also, you would want to use a slow speed grinder. This gives you better control, and it is safer to use. Share Pin. Bench grinders can easily handle just about any tool sharpening job you have How to use a bench grinder to sharpen tools: One of the key steps you need to take is to keep safety first.

Match the wheel to the metal being sharpened - it is the right tool for the job rule that always applies. For old tools, you may want to go with a 60 grit aluminum oxide wheel and medium hardness. Put the tools in your oven - not too hot just set your oven to degrees and let the tools sit inside for 2 hours. This treatment will help prevent cracking when being sharpened.

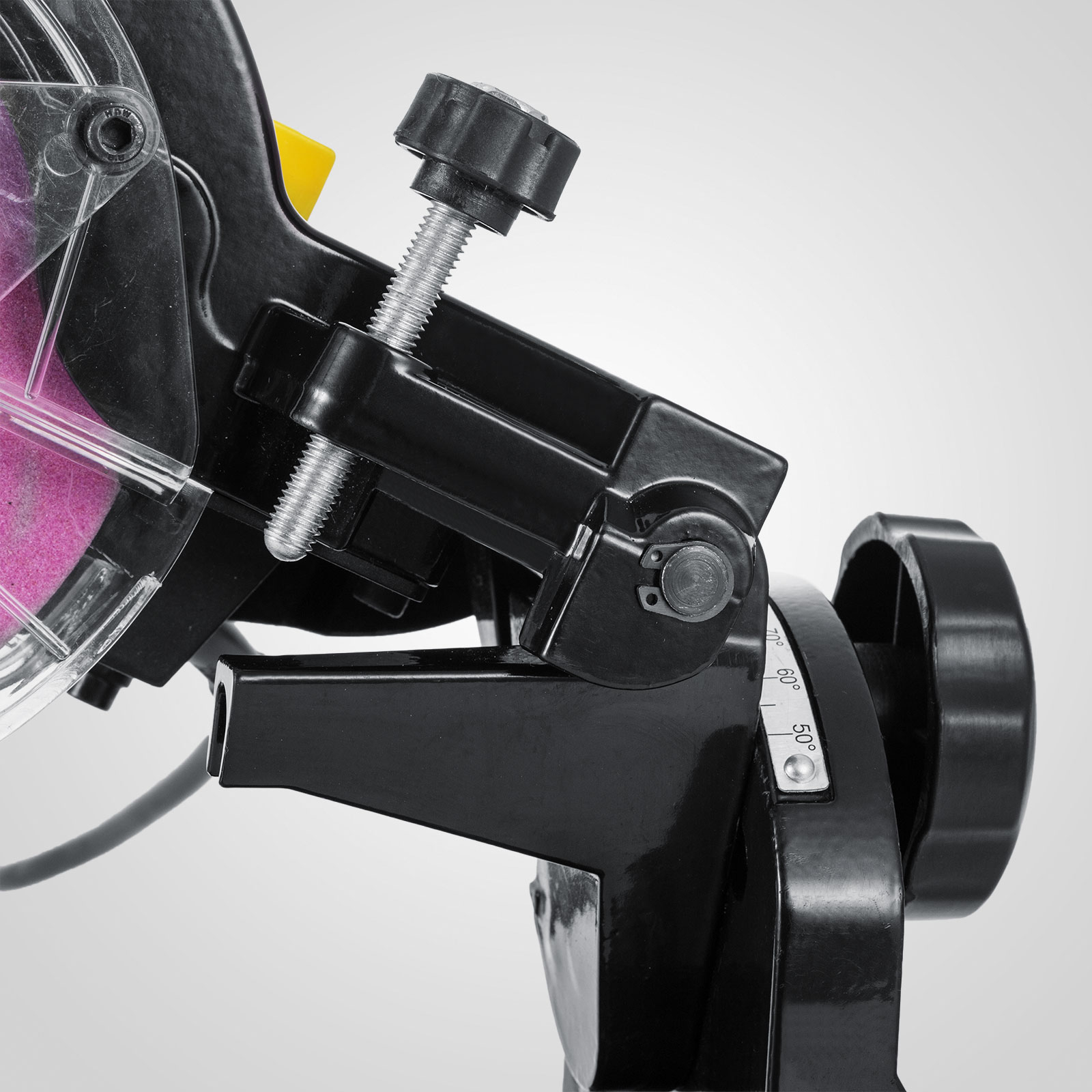

Use the edge of the grinding wheel to make short work of the mushroom look, then start on the tip. Take your time and do several passes. You need to be careful of any red hot pieces of metal that will come off as you grind away. Make sure you keep dipping it in cool water, oil or some other cool lubricant. Overheating the tool only works against you. Finally, use a wire brush - this will remove any rust that is on your old tools. V tool rests.

This is due to the purpose of each tool. The following instructions are for the diamond parting tool. This helps you keep the tool straight as you grind. Continue till you get the angle of your edge just right. Adjust the tool rest to match the angle of the wheel. Use the permanent marker to color the edge of the scraper.

Adjust the tool rest till you get the wheel to the middle of the bevel. Follow the shape of the edge. When the sparks begin to fly and land on top of the scraper and you can feel an edge, you are done. You want to have a flat bevel on both sides of the tool. Let the bottom of the tool hit the wheel first, then let the top side touch. You want to achieve a 25 to degree bevel with a swept-back edge. We use cookies in order to improve site performance, offer you a better browsing experience and enable you to easily share content.

Cookies are pieces of information stored on your computer in simple text files which our server can read and record. These files do not contain any sensitive information. By continuing to browse our site, you agree to the use of cookies. Thread Grinding Wheels. Toolroom Grinding Wheels. Surface Grinding Wheels.

Segmented Grinding Wheels. Cylindrical Grinding Wheels. Centerless Grinding Wheels. Creepfeed Grinding Wheels. See the full Thread Grinding Wheels range. See the full Toolroom Grinding Wheels range. See the full Surface Grinding Wheels range. See the full Segmented Grinding Wheels range. See the full Cylindrical Grinding Wheels range. See the full Centerless Grinding Wheels range.

|

Ultra Modern Woodworking Projects 3d Letter J In Italian Alphabet Lyrics Wood Porch Swing Plans Half Lap Joint Router Jig 50 |

KARABAGLI

16.09.2020 at 13:29:54

tana

16.09.2020 at 22:30:36

SEXPOTOLOQ

16.09.2020 at 15:11:57