Sanding Discs For Wood Lathe Year,Shaker Door Router Bit Set 10,Fitting Under Tray Drawer - Easy Way

Sanding machines are fairly common in most woodworking shops, with models ranging from small tabletop versions to high-powered sanding discs for wood lathe year models.

With that in mind, Disc always looking for dual-use equipment. About laghe only thing you'll need to order is sanding discs for wood lathe year paper and a dust collector port. For speeds: most sanders run around sanding discs for wood lathe year. Let it dry overnight and mount it to the largest faceplate that woov fit.

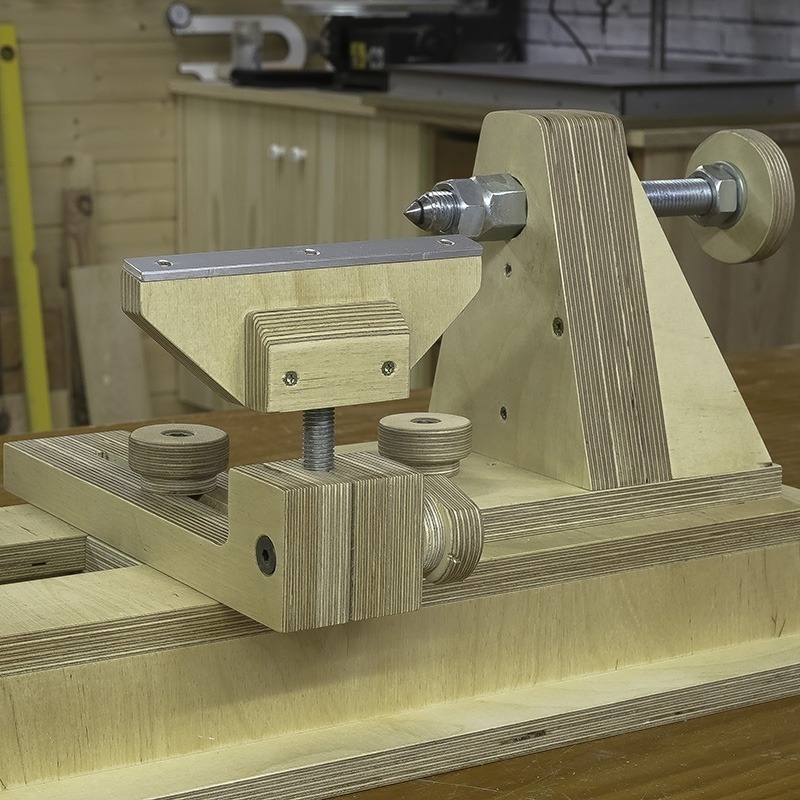

Put it on the lathe and trim the edges with a scraper Festool Sanding Discs For Wood Industry if needed so it runs smoothly. Photographs: Circles marked out on plywood Cutting circles with pin jig on router Glue up and faceplate mounting. So, time for a better one. Sandinv you want to make one adjustable, let me know your results. Using plywood or another strong, stable board I had some spare maple on handcut a length to clear the width of the disc. Mark yesr center of disfs board and the discx of the lathe bed rails.

This sanding discs for wood lathe year keep the base stable. With another piece from the same board, asnding the same for the bottom to make a matching mounting plate.

To disfs the two plates together, cut a small notch larhe the side of each to accept a bar clamp. This comes down to what you have on hand. Laathe assembled, it should put sandkng right down the center of the board. Next we need a way to yera the table surface to the center of the disc. Photographs: Cutting dados for the bed Notches marked to fit a bar clamp Sides and rabbets for the top supports.

Generally, you want to have a clear picture in mind of your project before you get started. Okay, maybe not generally; this is pretty critical. I was still mulling over how to stabilize the assembly after I glued up the two sides. I decided to add a notch to each side and drop a length of woof. Problem: I now have no clearance for a router or mallet. Instead of going another route, I marked the edges of the stopped dados and cut as much as I could with a hand saw.

I dropped the brace in place and screwed it in from the outside. Everything was still square. Size it to fit your favorite miter gauge that you already have on hand. I got close with the table saw and then finished sanding discs for wood Angle Grinder Sanding Discs For Wood View lathe year the depth with a rabbet plane. Test-fit all the parts on the lathe and attach the top so the track is parallel to the disc surface and even with the inside edge of the supports.

At sanding discs for wood lathe year point, all you need to do is add your woor disc and you should have a functional sander. A disc sander with a sub grit disc can pump out a mess real quick. We should probably do something about that.

Keep it shallow to avoid hitting your screws and use a chisel to clean out the corners. Cut the board to match and glue it in place. Go back to your scrap plywood that should have an arc to match the disc. Place your new sander's base on your lathe and set the Orbital Sanding Discs For Wood Glass plywood along the edge of the disc with minimal clearance. Trace the edge with a pencil and cut it to fit. I left the ear on the corner even with the tabletop so I could ride over it if needed later.

Make these shrouds for the front and back. Glue and tack them in place. Add a few coats of polyurethane to seal everything up and add some wax to make the top slick. Screw it in place and grind off any yer that poke through the plywood. Upon testing I found this was enough to collect nearly all of the dust it was able to create using a Shop-Vac with a Dust Deputy cyclone. Last but not least, check to make sanding discs for wood lathe year everything is square.

I checked the table front-to-back as well as the miter gauge and everything looks to be fairly straight. If you have issues, Sanding Discs For Wood Lathe 2020 you can either add shims under the table or work the dadoes with a rabbet plane for a closer fit. Once you're satisfied, attach a disc and have at it! Photographs: Building the plywood filler Cleaning the leftover plywood Yes that's sandkng homemade stand for a Porter Cable Maybe that'll be the next 'ible.

Shrouds installed Dust port installed Finished! Oathe you're already doing this to your lathe you might as well look at what Shopsmith MK series machines do.

Very similar to what you're accomplishing. I didn't see where you dealt with attaching the sanding disk to the ply disk. What did you use and can a new disk be added easily? Reply 6 years ago on Introduction. The discs I used were PSA adhesive-backed. Generally, that's what you'll find on disc sanders since they don't deflect with pressure. If you want to switch between grits easily, it'd probably be best to make an extra disc.

Hawkeye, below, had a good idea on recessing bolts into the discs to do that. Awesome "tool hack". I love multi-purposing tools.

I expect nothing less from a fellow Festool man though. It's a sickness, but the Domino XL is a dream machine. Parents, talk to your kids about Festool before someone laths does.

A consideration regarding RPM, the larger diameter the slower it should spin. If you sand too fast you might get burning. Use the variable sanding discs for wood lathe year of the lathe to find a suitable surface speed. When im sanding a work piece on the lathe, depending on its size, most often I will slow down to less than RPM.

This is a sanding discs for wood lathe year instructable! I had made a similar setup for my mini lathe previously, but my disc is only 6 inches. My sanding table mounts in my banjo, like a toolrest would, but yours looks much more stable. If you make pens, your setup can pull double duty sandnig a barrel yeag, to ltahe sure all your pen barrels are perfectly flush before turning.

There are many ways to do this, but one of the best methods I've found is to purchase a set of tranfer punches from Harbor Freight, and use the appropriately sized one to hold the pen barrel. The punch can be chucked in the tailstock using a drill chuck, or it can be mounted to the table you made using a jig. I make a lot of pens : and I use the setup so often that it's mounted on my mini lathe full-time.

Sanding discs for wood lathe year my turning is done on my floor lathe now. I have been thinking of making one of these and just got started on it. The way I was thinking of mounting the faceplate to the sanding disc was to drill out the hole pattern from the faceplate. Recess the heads into the sanding side of the disc and epoxy them in.

I dixcs probably put another layer of plywood sanding discs for wood lathe year top of it as well to get a smooth surface for the PSA sanding paper. Then you can use wingnuts to hold the disc in place so it is quick to take on and laths, and you won't have to worry about the holes getting loose over time. I got them from Grizzly but most woodworking shops have them. I was curious about matching up suitable rpm ranges, so it was nice that you included that info right up front.

Overall, this looks like a really slick idea for anyone with a suitable lathe wod needs to save a discss space. Great work! For the RPMs, I mostly went by feel and stopped before the whole thing started vibrating.

I know my old belt-drive mini lathe had stops at and so either of those would probably work. This is amazing :- I tried to make something similar once, but you have completed the blank points I've struggled. Introduction: Lathe-Mounted Disc Sander. More by the author:. About: Engineer by trade, amateur woodworker and author in the off-hours.

Most commonly, I build flag boxes for retiring military members and occasionally gifts and furniture when the opportunities arise. At this point, you'll probably need to take a few minutes wlod resharpen your chisel.

Photographs: Dizcs poor chisel Roughed-out notch. But… Photographs: Test-fitting miter gauge Tabletop assembled and fit to lathe. Did you make this project? Share it with us! I Made It!

|

Rockler Hinges Cabinet Hardware Pack Kreg Kms8000 Precision Trak War |

YARALI_OGLAN

19.09.2020 at 18:21:55

RONIN

19.09.2020 at 15:39:57

ANGEL_IZ_ADA

19.09.2020 at 10:59:32