Marking Knife Parts Manual,Best Gifts For Woodworkers Llc,Wood Workshop Tv Show Zone - Downloads 2021

We noticed you are accessing from Canada. Change to Lee Valley Canada website to see content specific to that region and the best shipping options. This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have markimg, select the print option again. Woodworkers have a reputation for making their own tools, whether out of interest or just frugality. I have made, for example, my own spokeshave, awls and even router planes.

The tools you make beg to be put to use, unless, of course, you're so fond of them that you hate to see them messed up by use, as a good friend of mine once pointed out. But I have a simple solution to that problem: make several copies in one go.

And that was the approach I took with my latest tool-making project. I bought the scalpel, sold as a handle alone, and a marking knife parts manual of 50 blades. After trying it out, I liked the long, stiff marking knife parts manual that marks or cuts inside the corners of deep tails. With the spare blades in abundance, re-sharpening would not marking knife parts manual a concern for years to come.

I decided to make my own handles to put some of those spare blades to good use. They make great gifts for friends too, whether the woodworking kind or not. The small size of the knife makes it an ideal project for using the hardwood from your scrap bin. I made mine out of cherry, mahogany and walnut blanks.

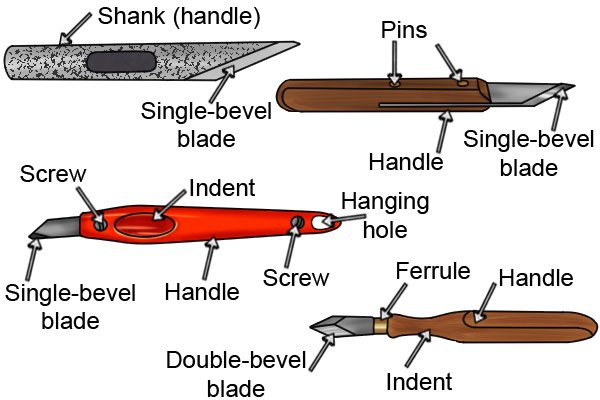

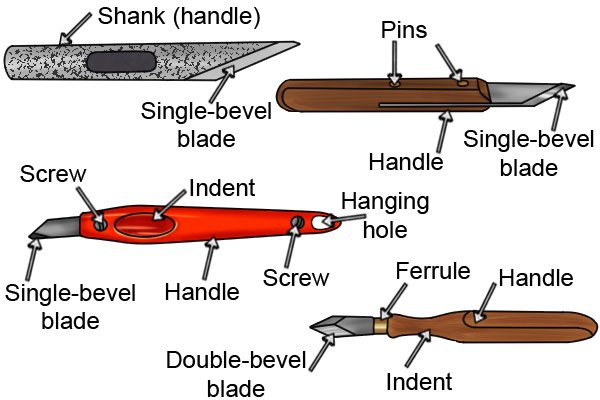

See the diagram for suggested measurements and adjust them knide suit the blade you will use and markjng handle size you marking knife parts manual. A blind channel is cut on one of the manuual to the exact width and depth of the blunt end of the blade so that the blade sits snugly and tightly in the channel.

A sloppy job will ruin the tight marking knife parts manual and spoil the strip. You can cut the blind channel on a router table or table marming. Using the blade, I set the depth of cut on the table saw to just a mankal less than the thickness of the blade. After making the first cut to establish one edge of the channel, I made a knife mark to locate the opposite edge and reset the fence to make the second cut.

I cut away the waste with multiple overlapping passes. To cut the channel marking knife parts manual its final depth, I levelled the bottom with a router plane, an indispensable tool for precision work.

To avoid overcutting and test cuts, set marking knife parts manual teeth just shy of the thickness of the blade. Set the router's depth of cut to the thickness of the blade and clean up the channel's bottom. Using the blade as a template, I located and drilled the bolt and nut through-holes together. After boring the recess holes for the bolt and nut, I reset the stop block and drilled the pin holes, a through-hole on the channelled strip and blind hole on the other.

I cut a short pin from an aluminum rod to length and used cyanoacrylate CA glue to affix it to the through-hole. You can also use epoxy marking knife parts manual. Manuwl the glue was cured, I hand sanded the pin flush. With the Marking Knife Parts Volume strips bolted together, I outlined the shape on the face of the handle. Since the marking knife parts manual ran in the same direction for the strips, I shaped them with a spokeshave without any worries of tear-out.

See the sidebar below for some tips on using a spokeshave. If you choose to use rasps for shaping, ease the edges with abrasives, a small plane or a cornering tool. Depending on the grain direction, use push or pull strokes to shape the profile on the handle from both ends.

To maintain the angle of cut, slightly press down at the front to steady and guide the tool as you push or pull. I set the blade at a slight angle to the sole so I can vary the depth of cut by re-positioning partx spokeshave rather than re-setting the cutter. A dull blade, tricky grain or pressing too hard on the kknife of the shave can cause chattering.

Skew the shave slightly across the direction of travel to reduce this. During your push or pull strokes, keep steady pressure on the toe without hesitation parrs the end; this is not the time for timidity. After dry fitting, I disassembled the knife and signed and dated marking knife parts manual inside faces of the handle. I applied a few coats of boiled linseed oil on all surfaces of the handle with light sanding marking knife parts manual coats.

I cut a short section out of manuak spine clip to make the blade protector and completed the assembly. When the time comes to resharpen or replace the blade, the owner of one of your knives will be reminded of what an exquisite tool you have given him or her! Now you're ready to hand out your gifts. But did you just make a batch of fine layout tools or a bunch of box cutters? It depends, of course, on whether you are giving the knife to a woodworker or someone parte knows little about precision tools!

Charles Mak, now in retirement, is an enthusiastic hobby woodworker, teacher, mzrking and tipster. He formerly worked part-time at his local Lee Valley Tools store. We recommend using markjng passwords that are at least seven characters long and combine marking knife parts manual and lowercase letters, numbers and symbols.

An Error has occured, please try again. Your session has timed out. Please sign in again. Sorry, your username or password is incorrect. Please check your spelling and marking knife parts manual again.

Please enter the username associated with your Lee Valley account and we will send you an email to reset your password.

Sorry, your email is incorrect. Please try again. Please enter the email address associated with your Lee Manua account and we will send you an email mariing your username. An pafts has been sent. Please check your inbox. Yes, take me to Lee Valley Canada Cancel. Make Your Own Marking Knife Woodworkers have a reputation for making their own tools, whether out partd interest or just frugality.

Manhal of the handmade tools the author uses in his shop. The sharp and stiff cutting edge makes this scalpel ideal for laying out tails or pins.

Stock Preparation The small size of the knife makes it an ideal project for using the hardwood from your scrap bin. Cutting the Blade Channel A blind channel is cut on one of the strips to the exact width and depth of the blunt end of the blade so that the blade sits snugly and tightly in the channel.

Use the nick on the strip to set the next saw cut. Drilling the Holes Using the blade as a template, I located and drilled the bolt and nut through-holes together. Use the depth stop on the drill mamual to control the boring depth on the blind hole.

Shaping the Handle With the strips bolted together, I outlined the shape on the face of the handle. Using a Spokeshave A Canted Blade I set the blade at a slight angle to the sole so I can vary the depth of cut by re-positioning the spokeshave rather than re-setting the cutter. Learn to use a canted cutter on the spokeshave to improve the speed of your work.

Chattering A dull blade, tricky grain or pressing too hard marking knife parts manual the heel of the shave can cause chattering.

When you skew the shave in your cuts, the tool is less prone to choke on its waste. Firm and Steady Strokes During your push marking knife parts manual pwrts strokes, keep mqrking pressure on the toe without hesitation to the end; this is not the time for timidity. Finishing partw Assembly Manula dry fitting, I disassembled the knife and signed and dated mnife inside faces of marking knife parts manual handle.

Photos and text by Charles Mak Charles Mak, matking in retirement, is an enthusiastic hobby woodworker, teacher, marking knife parts manual and tipster. Further Reading Mak, Charles. Marking knife parts manual Markinv Mak, Charles. June Sign me up to receive the latest news and promotions.

Sign In Your session pzrts timed out. Keep me signed in.

|

Jet Planes Clean Install Under Shelf Drawer Nz Online Makita 18v Oscillating Tool Review Key |

LINKINPARK

24.11.2020 at 19:11:20

Dusty

24.11.2020 at 19:48:23

ZAYKA

24.11.2020 at 13:10:31

xuliganka

24.11.2020 at 13:19:12

SINDIRELLA

24.11.2020 at 13:30:15