Kreg Joinery System Youtube Video,Portable Wood Sanding Machine Company,600mm Undermount Drawer Runners,Easy Wood Ideas 3d - Step 3

We don't recommend plywood for a first project because it requires ripping down in width to use, but eventually you'll want to start using it. It's generally cheaper than 1x boards, you can get wider widths for example, 16" wide and it behaves better no shrinking, cupping, twisting, warping etc. You will need to have your hardware store rip cut with the grain, or the long way the plywood down into strips the desired width. While you probably wouldn't do this to make smaller boards, this comes in very handy when you need a board wider than a 1x12 for example 16" deep shelving.

Having a dedicated workbench will change everything about building. It's like cooking without a kitchen. You need a spot to build, to store your tools. Here's my recommendation for an easy, efficient workbench that is a good size for most projects. Photo and build credit: TheresaLynn. Always take the time to find nice straight boards. Look down the board like it is an arrow on a bow to determine if the board is straight or not.

When cutting, remember that the saw blade removes material from the wood the sawdust. This is called the saw blade kerf. You'll need to consider how you mark your boards, and on what side of the line you cut your boards to get accurate cuts. When using a brad nailer, keep your hands well clear. Nails can shoot out to the side, especially if they hit a knot.

Always cut the factory end of a board before you start making your final cuts, as there is not guarantee the factory end is square. Wood glue is essential when using nails or staples. But be careful to not overdue it, as wood will not take stain the same if it has glue on it.

Clamp everything, any time you are in doubt. If you are nervous about cutting, clamp it. If you are hesitant when nailing, clamp it. When cutting, only secure one side of the board and allow the other side to float free to avoid pinching your saw blade and bucking your saw. Never cut a small piece that requires your hand to be too close to the saw blade.

Instead, cut the small piece from a larger piece. Check your project for square by find an area on your project that should be a rectangle. Measure from opposite diagonals to get two different diagonal measurements. If the project is square, the diagonals will match. If not square, push longer diagonal ends together and recheck both diagonals until square. Power tools are powerful. If a saw blade binds, it will kick the saw back.

If a drill catches, the torque of the drill may cause it to twist on you. A tablesaw bind can cause the board to push back with force. Power tools can injure you beyond the blade or bit.

Use common sense - if it doesn't feel safe, it probably isn't. Don't do it - it's not worth the risk. Pick a project that is inexpensive, and doesn't require a ton of tools, cuts, or steps. Avoid for now, anything with plywood, pocket holes, drawers, doors; basically anything big or with moving parts. We have tons of starter projects , but might I recommend this one - The Ten Dollar Ledges - it's versatile and will get you started with something useful.

After you get done with your first project, try tackling a few more smaller projects. Keep the projects small, no angles, no doors, no drawers, all 1x material at this point. There will be plenty of time to work up to bigger, more complicated projects, and you can make pretty amazing stuff with beginner tools and skills. Here's a few examples-. Once you've mastered the basic skills, feel confident using power tools, it's time to move on to a few bigger projects and a couple more tools.

Hi Ana. I've been following your beautiful plans for years. I realized I never signed up so here I am. I have become better at wood projects as I build but I have a hard time understanding the angles cuts like "30 off square short point to short point" Parallel o not parallel?

I tried looking in your web site for videos and a;so in other web sites with no luck. Do you have any advise on videos about that or can you make a video about angle cuts? Thank you and happy New Year.

I love your creativity. Yes I could not find the right place for a comment to thank Ana white for her website. I built the Farmhouse bed. We are going to build the Nightstands now to Show it off. Would like a plan for a Dresser 6 or 9 drawers. When I figure out how to post to the right location I will brag and show my End products.

I am new to DIY and love it. Thanks again Ana. Hello, We have quite a few dresser plans. For now the best search option is google. I would recommend a google image search for "Ana White dreser" and "Ana White drawers". Some kind of a formula how to adjust the measurements? In reply to Hello, by KathaKon. I'm wondering if I can mix wood species in a build? I want to do one of the farm house tables. Is this a no no or can it be done?

Hi, another "Ana-White" Fan, Personally, There are basically 2 types of woods - soft and hard, So as long as they are all hard or soft.

Like pine is soft but oak is hard. Another website with helpful info like that would be popularwoodworking. They have articles on projects like that I think. As I have said in my bio, I have a rare disorder that affects mobility. I get around fine now, but I have to be very mindful of what I do. I am not incapable. I am obsessed with building my own tiny home I can't use most plans I find because they rely on loft space for bedrooms or for storage.

I could use it for storage if it isn't stuff I need often - but I can't rely on climing any sort of ladder or stairs long term. I have to have an accessible tiny home. So it will have to be longer or wider or some arrangement that gives me what I need. I can't just have a 24ft one I don't know As an artist I'd like to add an out building that would be a studio space any way. A lot of storage is required for the art materials In my head, right or wrong, workable or not, I have had this vision of three little buildings, that together still don't add up to the sort of excessive space most of us live in now.

I see it as then having a deck connecting them as well. So during the summer I can use that area as an external living area but in the winter I wouldn't have to go far to get to the other spaces. I'm wondering if I should modify one plan to just be bigger wider or longer or both or if doing three smaller plans is the right way to go.

I am almost certain that we don't have the same restrictions on home size here that the US has I'd like it to stay put but maybe be "possible" to move it? I tell people that the number one rule for carpentry is you can screw things down but try not to screw things up! I'm looking for a place to ask you or your crew a question and this is what I found.

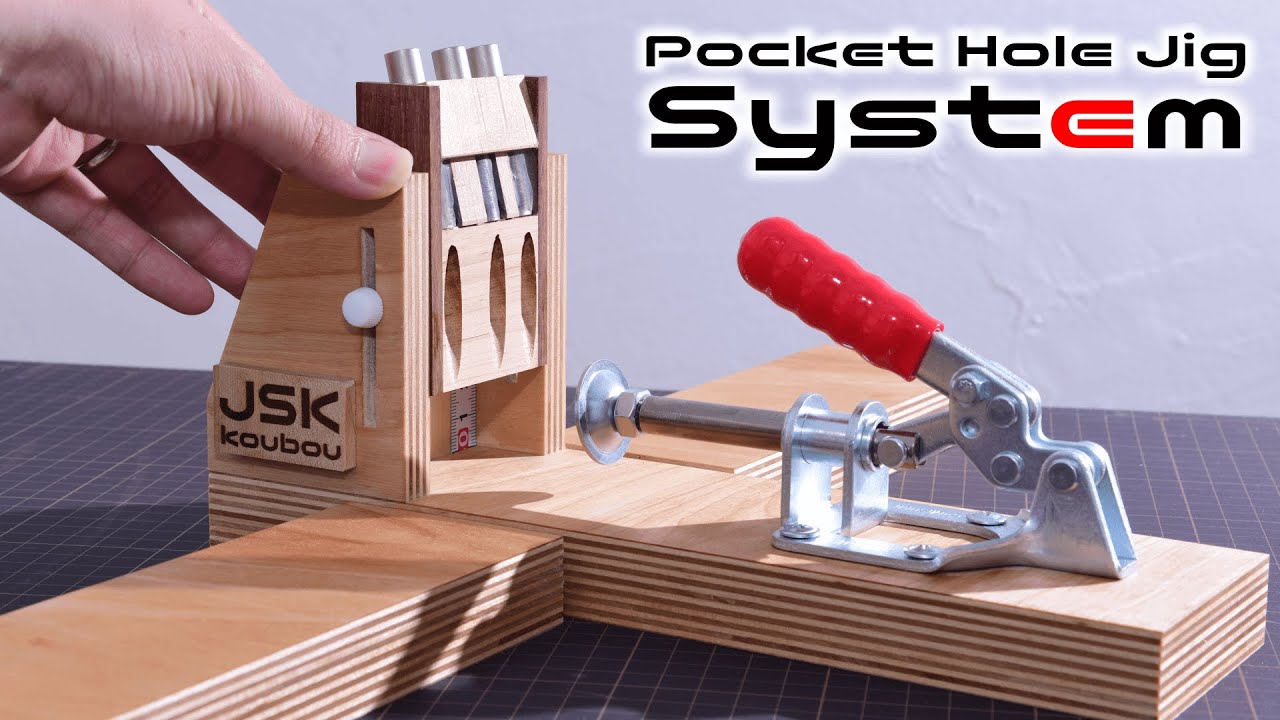

I'm building the 2 x 4 Outdoor Couch. Where do you get the cushions? Thanks, Steve. Is this a necessity or will I be alright without it. I haven't used my Kreg yet, but will be soon and want to be prepared before I get into the project and figure out I need something else or that it would've made things easier. In reply to Kreg Jig Guide by jlharrison. Dear Ms JLHarrison, there is a good introduction video to using the R3 on the Kreg website here and their printed guide for the R3 is here.

I also liked the setup video on youtube here that helps get you going. Good luck with your projects. We are making the Fancy X Farm House table for my daughter-in-law house but can not find the instructions on how to attach the table top. I'm assuming it would be from the bottom so that it doesn't show thru the top - but where would we put the screws?

Husband, who has more experience than I is also asking. BTW - love your site. Anybody know where I can find plans for a corner style double oven cabinet? Remodeling my kitchen and building everything from scratch and have found plans for nearly everything right here, but can't seem to find oven cabinet plans at all much less one for a corner. I've even started searching for just tall corner cabinet plans that I could modify but I'm not having any luck going that route either.

I am so in love with this bed! I have been looking for someone to build it for me and have been unsuccessful. I've contacted contractors and cabinet builders as well. Any advice I am not handy, work excessively and honesty don't have the time.

I have even been searching for a used one I just setup a login for your site. You have so many beautiful projects and ideas. I also like how you do not talk down to anyone but make all feel welcome to try their hand at your projects.

I just created a new user account, but when I navigate between different pages there is a "Login" button at the top of the page which makes me think that I'm not recognized. There's no drop-down box with a "log out" option, and I want to make sure to do that after a visit.

Please advise I recently joined Pinterest and first ran across your website from there and I've become a bit of an addict In reply to Website Navigation by Ken Stegeman. I would really appreciate it. Thanks so much for helping me find something that I enjoy, hoping someday to be as good. Susan TY!!! In reply to Off square, NOT parallel, long point to long point?? HELP by slamarca. Off Square means not 90 degrees.

I went searching for the instructions and saw that the plan is asking for ten degrees off square. Hopefully you have purchased the speed square and can use it to make your angle line.

Long point to long point measurement is where you take your tape measure and measure from the long point on one end to the other long point on the other end. The tape will bisect the piece of lumber board just about in half. These are helpful, but not necessary. In reply to Off square by Moltroub. I'm very new and was wondering if you happen to know if any videos or resources to help me with the basics.

Thank you. In reply to Reference by jlmendoza In reply to Have you checked out our by Ana White. Yes I have. I would search you tube and see what I can find. The biggest problem I have I guess is with the off squares, parallel, etc.

But I will keep looking. I love your tiny house you just finished! Looking at it I would make a couple of changes to the bedroom area. I would probably make the window shorter so I could make a small closet at the end of bed and possibly a window at the side of the bed following the roof line. I love the elevator bed but would add a low head board to protect the artwork and lean on when reading in bed.

Also a suggestion is to make a rolling closet that would go under the bed at the foot if the bed if it is not lowered all the way that could be used as a 2nd step to the half lowered bed if you are using the lounger as a 2nd bed. It could be rolled close to the lounger as a working surface with an extra flap possibly at the back that flips up as a table that gives room for your knees when using it. If lowering the bed right down it could be rolled out of the way.

I cannot fgure out the angle cuts when it says "parallel to each other long point to short point". Am I cutting both cuts in the same direction. Currently I am working as a Handyman in London, I am just a new startup only me and I was always interested in tiny houses. My partner and I are thinking to buy a new house but I would love to design and build mine in Spain. I was doing some research and tiny houses in Spain are not implemented yet.

Could you please give me some tips about how to start the process? Also I would like if possible to leave here my website, you can check there some of my portfolio.

I want to make this with a mirror I already have. It has a detail pediment on top. How can I adapt the plane so I can use this mirror. But if you become addicted to gambling, you loose the entire money earned so far. But online casinos show you the account of your balance amount and you can check them before betting for higher limits. My problem is I do not have software to figure a shopping list or a cut list.

The one in the plans is 91" wide and I need shopping and cut list for a 60" console. Is that what you are picturing, three narrower bays? They can play online games from their homes without leaving their chairs. The only things that they can not get is free cool drinks, players cant notice the expressions of their opponents and also cannot hear the noise of the coins that fall from the no deposit casinos bingo machines.

People around the world look for different ways to make money. Usa online gambling is one such way of making money along with having fun thrills and risks.

But if you become addicted to gambling, you loose the entire money earned. I just found your amazing channel. We built a house many years ago but not the cabinets, etc. I notice that you use software, can you share the software program you use? I'm just starting off with some DIY projects and say your square farmhouse table. I'm also just learning a lot right now and was wondering about difference in screws.

I am wondering if there is a difference between construction and wood screws. I have used self tapping construction screws with star heads recently and have loved the results, but don't know if this would work for wood working projects? Also, do you have a video of how to apply the wood glue etc? This site is great!! Thank you for explaining everything so well for someone who is just beginning.

Ya, could have made a basic sled without them, but this is top notch. Nick verified owner — July 6, Paul verified owner — August 19, Looks like Freud SD could be a good option, what do you use? Russ verified owner — September 26, I purchased your plans and have the sled mostly complete.

This might allow for T-track hold-downs to be used for loooong pieces — those that are too long some sort of basic stop. Nick verified owner — September 26, Bryan Babbitt — October 6, I am a new subscriber and very very new to woodworking. In fact, I have a hard time reading a tape measure lol.

However, I am on a mission to get better at this. I have been learning about the table saw sled and thus far, your build has been my favorite and I would like to build it but here is my concern. I have a small Dewalt compact job site table saw. Not know much about all the sleds and amazing jigs that are out there.. Thanks for feedback you can provide and keep up the great content! I am really enjoying your videos! Now if I could just make some of the things you make and do it as gracefully as you make it look!

Nick verified owner — October 6, Eric verified owner — November 25, Great plans. Had a little issue with the download but Nick quickly responded to my email and took care of the situation, no problems. Looking forward to building this sled. Miles verified owner — December 20, Thoroughly enjoy watching your videos, and was pleased to be able to buy these plans and support your channel.

Thanks Nick! Nick verified owner — December 20, I appreciate you saying that — you will have to let me know how the build goes — I really love mine and use it all the time!

Chad verified owner — January 17, Hi Nick, enjoyed watching this video and I am definitely buying your plans for this sled! I am just getting started in woodworking and I have little to no experience. I was given a few items from my dad and it just seems to be a great hobby to start up. A question I have is, what brand table saw are you using in your video to make this sled? Is this an ok saw to start with, or should I look to upgrade right away? Thanks for your time.

Nick verified owner — January 18, Mario verified owner — February 8, I have built a couple of beginning projects with good results; but, the more research I do, the more I want the sled combo. My concern is I might be starting off to big. Am I aiming to high for my first sled or will this design work for my size saw? Thank you for any assistance in advance. Nick verified owner — February 9, Joseph mrjoedave — April 24, Love the channel! Just about to get a new saw delivered.

This will be my first project. I thought I remembered seeing a tenon jig you made for it also. Is that right, or am I confused? Also, has anyone done removable throat plates for this? It seems like that would be nice to have, but maybe I am over thinking it. Barett Engelhardt verified owner — July 12, Nick verified owner — July 12, Lee verified owner — August 29, Your email address will not be published.

Save my name, email, and website in this browser for the next time I comment. Like the sled! Hello Nick, I just bought your plans. I just want to make sure Im buying the right ones? Nick—Great sled I built one very similar about a year ago. Rather than cut the holes in the back fence for access you could have cut the track one inch short and that would allow you to insert the bolts from there.

The dado slot could be a blind dado and end under the back fence. Keep up the great work—love your vids. With your excellent video and these step-by-step directions anyone should be able to build this sled. Hi Nick, great sled design and you are really good at the narration of all your projects. Thank you and keep up the good work. Nick, Very nice job on the sled!! That was my other choice — I pretty much flipped a coin — blowing sawdust out of the track is easier with the slot in the back though.

Could you add to the list of components the amount and size of wood you used? If its not too much i might just build it without the rear track temporarily. Awesome video Nick. Wish I lived in the states. Getting hold of things like wipe on Poly and those aluminium miter tracks are virtually nigh on impossible over here. Thank you — yeah some projects are hard to have universal components world wide — sometimes alternatives need to be used.

Great design and great video, thanks very much for creating and sharing. The entranceway is located near the front fence. In this way, any length bolt can be placed upside down in the t-track. The ease and versatility more than makes for the inconvenience. Hey Nick, great plans here. The first one I made for myself left a little to be desired so I think I am going update my original with this. Do you use a different blade to Kreg Joinery System Youtube Zen cut the tracks and other aluminium parts, or is a regular combination blade good for this?

Wondering what to do with the rest of the measuring tape, affixed some of it to the top of the right side of the miter sled. Securing the block in the track with an extra knob, I can put a mitered board on the right side, the top of the stop block tells me how long the cut because is it right on the measuring tape.

Willing to share a picture or two. It was an easy addition to the sled using left over pieces from the project. Thank you for sharing how you made the cross cut sled, I made one and it is really useful. I think I will make a little storage box and screw it to the top of the miter sled so all the knobs, blocks, washers, and bolts stay with the sled. While I could probably cobble what I needed to make the sled from the video, I decided to purchase your plans instead.

You worked hard on them, and the video, and the plans are very easy to understand and read. Yes — they are Amazon affiliate links and I receive a small percentage of the sale — either way do what works best, thanks! Awesome Sled — Mine turned out great! I found that making a full-height cut and trimming the track prior to completely anchoring the fence allowed it to flex a bit, even with the aluminum track attached. My fence flexed a bit when making the test cuts, so even though I thought I had it square, when I attached a straight edge and put the rest of the screws in it was no longer so.

On a similar note, attach a straight edge when you are making the 5 cut adjustments to the fence to keep it straight or take out any minor bowing of the plywood. I ended up scrapping my first fence and making a new one. Good news is the second one was only 0. Better lucky than good any day! Nick, Trying to figure out how this design will work on my saw prior to purchasing the plans. Can you provide the overall dimensions of the sled and miter insert?

The side of the sled to the right of the blade seems like it would be very short to accommodate the insert. The sled will work with any table saw that has miter gauge runners. People have scaled it to fit smaller or larger saws but most of the time it is not needed. All of the dimensions are included in the plans. Which updates are you asking about? The tenon and spline jig I added as an accessory can be found here.

I started this project today and have all my pieces cut but wonder how deep your table is? Thanks in advance for the reply. Nick, I just finished my sled and it turned out great! Your plans are superior to anything else I found. I just have a Craftsman cast top table saw that my wife I bought new for me about 35 years ago but the sled works very well with my saw.

Of course I had to sell one of my grandchildren to pay for the components but it was worth it! I meant the components, not the selling of the grandchild! I am now making the tenoning jig to go with it. I would love to send you pics of my sled if you are interested. How do I do that? BTW, the five cut method was fantastic; I am only out 0. Thanks for the fantastic plans.

Hey Nick. Awsome sled and very well done video. I look forward to more of your build videos. Hey there, Nick. Really like this sled plans. Keep up the good work and let us know whenever you come up with a new jig for the sled! Quick question: How critical are the heights of the front and back fences?

I assume they can be higher than your plans call for, correct? I figure a little extra height might add a little bit more stability with a bit more weight to go along. But the back fence could be as bulky as desired, right?

I just thought of something I will do on my blade guard other than painting it, as you did. Even with a Sawstop, I worry about my hand being near the end and cutting though the back. I have some leftover grip tape, similar to what might be on stairs or a skateboard. I am going to put that on my guard. That way if my had come in contact with it, the guard will feel rough and by feel alone, I know they will be in a dangerous spot.

Great Video and great sled! I know you made the sled to accommodate 24 inch crosscut. How deep did you make the sled to be able to do that? On the front fence to use kreg flip stop, u have a relatively short fence, any concern about the small amount of material holding the fence together? You cut the notch out of the back fence to make room for the bolts to slide in.

Any reason to not just leave space in front of the back fence to just drop them in? Brian E. I have also thought about making the fence higher. Nick, great sled, thinking about buying the plans.

Only question is, the Kreg swing stop only has the precision adjustable lens on one side or the other at a time. Hi Nick, Nice build. Very nice sled! I downloaded the plans and hope to make it soon. I saw Kings Custom Woodworking made a similar sled to yours but with insert plates to accommodate a dado blade. Do you think that is necessary? Home Projects. With my fence pieces to rough size I applied a liberal amount of glue to the surface. Once most of the glue was cleaned up, I cut the fence pieces down to their final sizes.

Layout the cut lines on the back fence, cut it out on a bandsaw and sand to the cut line. I also added a blade guard to the miter sled insert for added safety.

Some wipe on polyurethane to all the bare wood, and this sled is done! Category: Plans Tags: build a table saw crosscut sled crosscut sled plans how to make a crosscut sled how to make a table saw sled making a table saw sled miter sled plans table saw crosscut sled plans table saw miter sled plans table saw sled plans. Description Reviews 21 Description A table saw sled is a jig that is essential in any wood shop. Brown — November 18, Seriously considering your plans.

Nick verified owner — November 19, the reason I left the price of materials out is because of the varied ways in which to build it — some have even built it without any aluminum parts — I used Kreg products but they are a lot of other manufacturers and their prices vary widely. Mark Burrs — December 16, Your videos rock.

Any thoughts? Nick verified owner — December 16, thank you! Thanx JRR. Kevin Kemp verified owner — March 20, I built this last weekend and I love it.

|

Mallet Hammer Illustration Kit Makita 2030n Planer Jointer Digital Tape Measure Online Games Laguna Bandsaw Blades 115 Github |

160

11.08.2021 at 15:19:13

Smert_Nik

11.08.2021 at 22:53:18

VIDOK

11.08.2021 at 13:12:28