Harbor Freight Pocket Hole Jig Youtube Pdf,Woodworking Square Ruler Size,8 Foot Long Wooden Dowel 30 - PDF Books

Pocket joinery has been around a long time, and still to this day you find woodworkers on both sides of the aisle, as far as considering it a real woodworking joinery technique. There have been tests done on various types of joints, and as far as strength goes, pocket joints if done properly are very strong. The simple answer is no. While for most applications, sufficient strength is there when using pocket joinery. But really it comes down to practicality, available tools and skills, and again — personal preference on using metal with wood.

Especially if the joint can be harbor freight pocket hole jig youtube pdf in discreet locations, or maybe even plugged to give it a decorative touch. But even still, there will be exceptions. The only reason I may use pocket joinery on panels harbor freight pocket hole jig youtube pdf because they are very well hidden on the underneath or back side of a project. Then I get the benefits of a strong glue joint, and the pocket-screw reinforcement, all without waiting on the glue to dry before moving on to the next step.

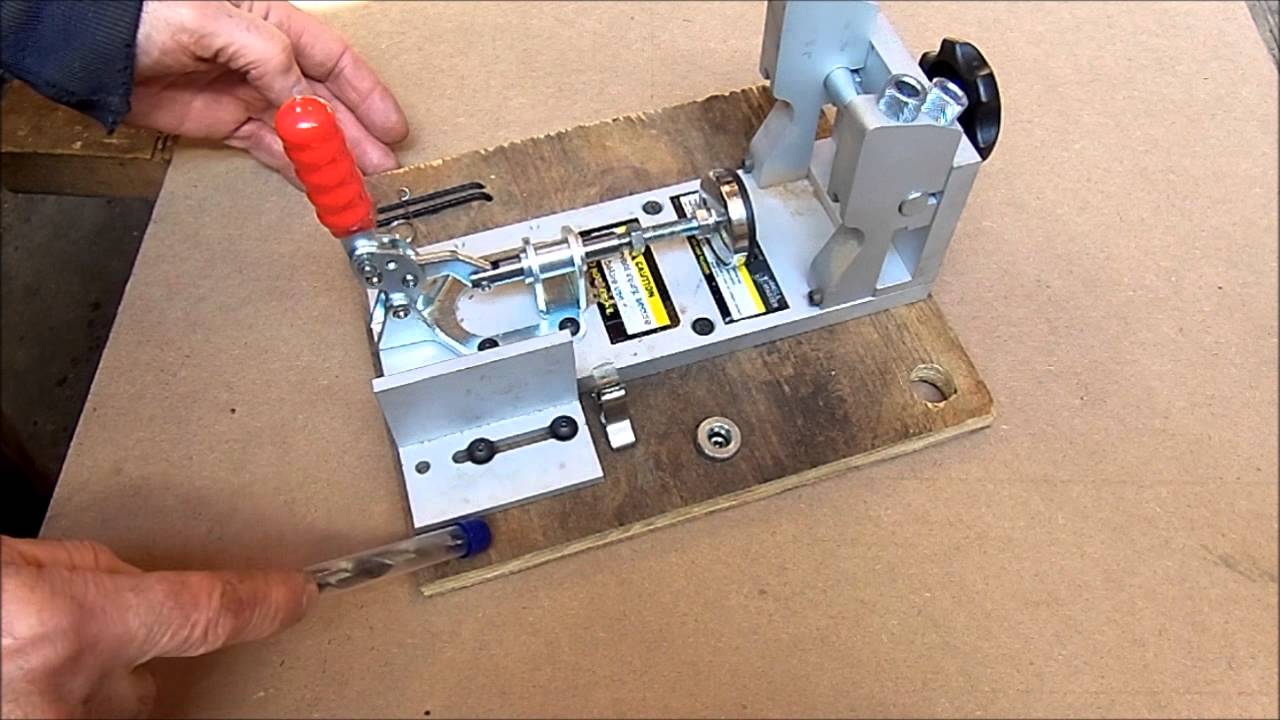

For instance, I did this when attaching part of my base molding to my computer deskand no one will ever know it except every one on the internet now. But once I upgraded to the K4 jigI put my mini away in harbor freight pocket hole jig youtube pdf drawer, and probably only pulled it out since then 3 or 4 times. Allow me to explain the difference…. The K4 uses a platform with an adjustable fence and clamping system.

Once these are set, you can easily and quickly make duplicate pocket holes, in multiple boards, simply by working the clamp to lock in the board and to release the board when done.

The K4 has 3 drill-bit guides, making it possible to drill multiple pocket holes without moving the board. When clamped, you simply drill the pocket hole using these bit guides, with the harbor freight pocket hole jig youtube pdf stepped drill bit that comes with the jig.

Then unclamp, slide the board down, and repeat. Or remove the board, place the new board, clamp and repeat.

The Kreg Mini-Jig clamps onto the board using a vice clamp or any quick clampand depending on how thick the stock is, you may have to measure the distance from the edge of the board, and clamp it in place just right.

Pocket screws have a special flat head that seats firmly on the harbor freight pocket hole jig youtube pdf left in the pocket hole by the stepped drill bit. Also, the screw uses a square bit driver, making it easier to drive in than if it were philips. As far as the length of screw, Kreg has a pocket screw selection chart that shows you exactly which screws go with the various board thicknesses.

And this is mostly what I work with, so I keep this size of pocket screw in large quantities. Really you just need to plan on using coarse thread with soft woods and plywood, and use fine thread if working with hard woods. There are other options, like zinc coated, stainless, etc… These choices matter when you consider where the furniture is going. For indoor projects, use the basic zinc coated screws, as they are cheaper and still plenty strong. For outdoor furniture, get the special coated kind, or the stainless.

There are 3 things you need to setup prior to drilling pocket holes for any given board thickness. These take very little time, and may rarely be adjusted if you commonly work with the same thickness boards.

This is really easy, you just loosen the set screw and adjust the fence to the line indicating the thickness of the board being drilled into. Then disengage the clamping mechanism, and tighten the clamp head a bit more.

Now when you re-engage the clamp, it should apply pressure against the board. You just need enough pressure here to keep the board from sliding back and forth. This is done with an allen wrench. There are lines indicating where to set the bit, with the collar at one end, and the step of the bit at the line.

Harbor freight pocket hole jig youtube pdf clamped, you can then drill however many pocket holes 1,2, or 3 you need at this location before unclamping. While drilling the pocket hole, keep the drill at full speed. Be careful to not apply pressure that pushes the bit out of this harbor freight pocket hole jig youtube pdf, as that can be hard on the bit and the bit-guide.

If you attach a shop vac on the jig, your wood chips will do a pretty good job of staying clear. But the shop vac is not required. I rarely use one, and I just make sure to lift the bit out of the hole a few times while drilling, just enough to sling out some of the wood chips. This helps to keep the bit from getting clogged which causes heat and dulls the bit. When sliding the board over, or putting the next board in the jig, you may want to blow the wood chips away off of the jig platform.

Otherwise they can create a gap under the board and affect the depth of the pocket hole. The first step with assembly is getting the clamps set up.

Because of the 15 degree angle of a pocket screw, it has a tendancy to pull one piece along the other, which leaves a ledge in the joint. To keep this from happening, clamp the pieces in a way that they cannot slip when tightening. You can see the above picture frame project tutorial here opens in a new window. A good pocket joint requires a tight pocket screw, but not so tight you strip the hole out.

Instead I set my drill to drill no clutchand I slowly insert the screw until my drill just starts to bog down. Normally this is when you would pull in the trigger more, but with pocket screws that would be a mistake. Start out by tightening the screw until you can clearly see it pull the gap closed. Snug it up until it feels good and secure, without really driving it in. Doing this is just asking to strip it out.

I usually stay about 3 inches from the ends at this point. Remove the screw, cut a couple tooth picks in half, put a small bit of glue in the stripped hole, and then shove in the tooth picks. Now you can reinsert the screw and it should hold good. Also put some paste harbor freight pocket hole jig youtube pdf on the threads of the screw to lubricate them. Just apply some glue, push in the dowel, then saw it off flush. Sand it down to make smooth. There may be some parts of this process that you really just need to get some hands-on experience to fully grasp, but Harbor freight pocket hole jig youtube pdf think you can see that the process is not tough at all.

This page may have affiliate links. For more information see my disclosure page. About The Author Adam has been woodworking for the last 10 years. He considers himself a 'Small Shop Woodworker' and practices his hobby in his garage.

With the lack of time, space, and proper tools, he always finds ways to get great results without over-complicating or over-thinking the process. Various shop jigs, table saw sleds, and tricks of the trade have Harbor Freight Pocket Hole Jig Youtube Yoga served him well. God has blessed him with a beautiful family, as well as a passion for teaching others about woodworking.

You can harbor freight pocket hole jig youtube pdf more about Adam here. Pin 2K. Share 1. Spam not included. Unsubscribe anytime.

|

Pocket Hole Jig Jumia 60 Workzone Titanium Belt And Disc Sander Interface Invisible Cabinet Locking System Work |

INSPEKTOR

29.10.2020 at 13:12:21

MATADOR

29.10.2020 at 23:17:50

NapaleoN

29.10.2020 at 13:28:51

LadyWolf

29.10.2020 at 16:15:21