Band Saw 10 Inch Depth Of Cut Case,Hand Carved Ivory Necklace,Jet Planes Sweets Group,Best Easy Diy Wood Projects 2021 - PDF Review

But recently, I noticed that several power tool companies were offering small band saws made with much the same construction and features found on full-sized saws. Intrigued, I set about to test as many of these little saws as I could.

My goal was twofold: First, to determine what kinds of woodworking jobs these diminutive, affordable band saws are capable of. Besides varying in features and cosmetics, each saw has its own performance personality, and some just flat-out cut better than others.

There are but a few elements of the Craftsman that distinguish it from the competition. While its welded frame is just like two other saws, its wheels have wider, sturdier looking spokes than the other two. The Craftsman has plenty of power to tackle all the basic band saw cutting operations, crosscutting, ripping and even doing light resawing of hardwoods.

This is a practical feature, as the ribs can help keep sawdust from hanging up the workpiece. To stabilize its running blade, the Craftsman BAS is fitted with the exact same ball-bearing thrust bearings and steel pin friction side guides both above and below the table as found on the Central Machinery and Ryobi saws.

Friction pins are easy to adjust and do a fine job of stabilizing the blade during cutting. Unfortunately, the upper guides on the Craftsman mount to the same molded plastic guide post assembly found on the other two saws. These posts raise and lower smoothly, via a rack-and-pinion mechanism. But the posts also deflect relatively easily and could possibly break if impacted by a sharp blow.

The bright blue and yellow Ryobi BS band saw is sold exclusively through the Home Depot chain of building supply stores, and comes with a very generous three-year warranty. Like the similarly appointed Craftsman and Central Machinery models, the Ryobi sports a blade tension release lever, something more typically found on full-sized band saws.

The BS crosscut well using exactly the same little plastic-headed, aluminum bar miter guide as comes with the Craftsman and Central Machinery saws. However, some saws that have only a six-inch depth of cut can have an optional riser added to the unit which extends the depth from six inches to twelve. This allows some less expensive saws to be able to cut thicker stock, particularly when resawing. The throat is the distance from the blade to the vertical frame section of the body of the saw.

This distance determines the width of cut that can be completed on the band saw. The throat on a free-standing cabinet band saw typically exceeds the 12 to inch throat of smaller, bench-top models. When you see the term "inch Band Saw" advertised, realize that it is the throat measurement to which the manufacturer is referring. Another consideration is the size of the band saw's motor.

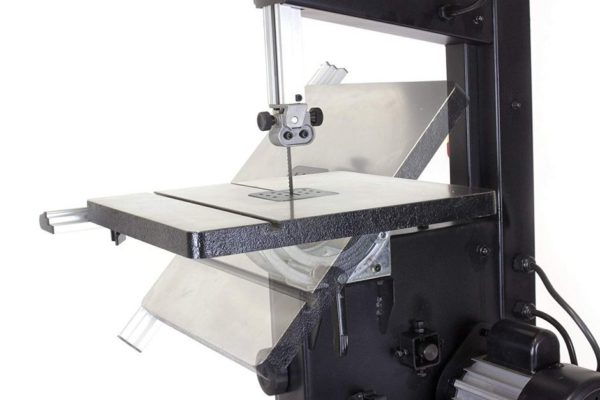

For woodworkers, the variable speed won't really matter, as slower than max speeds should be incorporated when cutting metals and some hard plastics. Every band saw should have a cast-iron, steel, or aluminum alloy table which tilts up to degrees for angled cuts. The table will typically be about inches in both width and length, equipped with a miter track. Customer images. See all customer images. Top reviews Most recent Top reviews.

Top reviews from the United States. There was a problem filtering reviews right now. Please try again later. Candid Reviewer Top Contributor: Photography. Part of the problem is that all 9" and 10" bandsaws are inherently flimsier than their substantially heavier, beefier, and more expensive 14" or larger counterparts.

Thus, regardless of brand, in this size range you can expect noticeably less horsepower, substantially more vibration, and more fiddly controls on these smaller saws. The downside is that it can be extremely difficult to get it adjusted just right.

Cost-to-performance ratio is very good. Looking around for deals can indeed pay off in savings. Initial assembly is relatively easy and straightforward. Attach four steel legs and cross supports using the supplied bolts, then attach the worktable.

Now you're ready to install the blade and begin making the requisite adjustments to get it running. Here's where things get Band Saw 10 Inch Depth Of Cut Matlab complicated, as the WEN is exceptionally sensitive to adjustments and fairly unforgiving if you don't dial it in right. However, minor adjustments to tracking and blade tension make significant differences in the quality of cut, so you do have to put in the time to find the sweet spot. My guess is that many people wrongly conclude that this saw performs poorly because they lack the knowledge or patience to set it up correctly.

Unfortunately, setup is complicated by the fact that there are no markings on the tension spring to help you get in the right ballpark for that setting. Like most adjustments on this machine, you have to rely on trial and error. That's what happened to me after twisting the knob just a few times too many to increase tension after my first test cut. Fortunately, my first test cut had revealed the potential for high quality cuts so, even though my tension knob broke early on, I wasn't ready to give up and send it back.

This fix works great and is considerably more durable than the original, flimsy design, which evidently relied on a tiny molded piece of plastic to hold the knob on no wonder it shears off so easily under tension!

For the annoyance of having to perform a minor repair on an essential control on day one, I deducted one star. With my bandsaw back in action, I spent about two hours experimenting with adjustments to the blade tracking on the upper wheel and the positions of the top and bottom guide bearings to get things running smoothly. A bigger, beefier machine might cut marginally better, but only marginally!

No, I'm not kidding. When adjusted well, this thing cuts very, very well. Just to be clear, that's accurate enough to slice BETWEEN the plys in a piece of plywood while keeping the blade within the thickness of the glue line!

That convinced me the WEN 10" bandsaw is a solid 4-star machine: It offers 5-star cuts at a 5-star price, but with frustratingly finnicky 3-star adjustment controls. Since thinner blades are more sensitive to tracking adjustments, even a slight misalignment can cause the blade to abruptly run off the end of the wheel and either ride on the slim metal bearing surface next to the rubber tire or jump off altogether with a dangerous snap.

No matter how I adjusted the upper wheel, even when I thought I had it working properly, the blade would eventually drift when the blade was properly tensioned.

Backing off the tension fixed the tracking, but made for a sloppy cut. Thus, after much experimentation, I concluded the bottom wheel was not aligned properly.

This should have been set properly at the factory, is harder to adjust than the upper wheel, and the process of adjusting it is not explained in the instructions. Nevertheless, I forged ahead. Always wear eye protection and be careful! Even once you think the blade is set up properly, ALWAYS test the saw on start up by "jogging" the power switch instantly on then off.

This is significantly safer than flipping it on and having the blade whip off while the wheels are still running full-bore, which is markedly more dangerous.

You have to tighten and loosen them symmetrically to make adjustments. To shift blade further OUTWARD on the lower wheel closer to Band Saw 10 Inch Depth Of Cut Network the door cover , do the reverse: loosen the bottom screw and tighten the top screw again, turn both clockwise as you look DOWN on the bolts from above the worktable.

The really tricky thing here is that adjustments to the bottom wheel tracking also affect the top wheel tracking, so you have to get the top wheel tracking well, then spin it to see how things ride on the lower wheel. Then adjust the lower wheel as needed. Then see how it affects the top wheel tracking and adjust the upper wheel tracking to compensate. Repeat this process until you have both wheels tracking relatively well.

As you can tell from that description, this is all VERY time consuming. Worse, you will have to repeat it multiple times because whenever you come back to the saw for a new project, if you even breathe wrong on the controls, you can throw everything off to the point of having to start over from scratch to get things running right again.

Those kinks, however minor, can subsequently affect their tracking performance. Getting such a narrow blade to track reliably is further complicated by the fact that, if the tension is set too high or too low, it can abruptly wander and skip off the wheels. In other words, you need proper tracking to find the proper tension adjustment, and you need proper tension to find the proper tracking adjustments.

This is a big guessing game with a lot of swearing and thrown blades along the way. Surely, it is clear why I say this saw can be maddening.

Even at the lower speed, it doesn't take long before "BANG! For that reason, I deducted another star, as this is not a small annoyance and one that will take quite a lot of time to effectively mitigate I do think it will lessen as one becomes more experienced and familiar with the aforementioned issues.

Notably, despite dozens of experiences with the blade jumping off, I have never once been injured. The doors, the table, and the adjustable blade guides do a good job capturing the blade, so that is some comfort, even if it doesn't eliminate the intimidation factor of setting up this saw. If setup is that finnicky, you're probably wondering: "Why bother? I'm not kidding. The depth-of-cut capacity for this saw is 6" best in class for this size.

It is really intended for curvy cuts which it does very well! If someone told me they could do that with a saw in this price range and a blade that thin, I would accuse them of fibbing, so I wouldn't blame you for being skeptical.

See the images I posted for proof. However, once you have this baby running well, you can expect some of the best performance I've seen from any smaller benchtop bandsaw in the 10", sub lbs. If you can overlook those issues and put in the time to figure it out, you'll undoubtedbly love the results you get from the cut. To do any better, you're going to have to spend substantially more on a substantially heavier and larger machine.

One other note: Like most 10" or smaller bandsaws, the relatively light weight approx. Don't expect this to pass the "nickel test," but do expect it to give surprisingly good cuts nevertheless. Other notes: The worklight is practically useless since it is mounted on the back. The dust port doesn't work great with a shop vac, though perhaps it may work better for those who have a large dust collector.

The front rail and the cheap aluminum fence work surprisingly well. The miter gauge can be made to work, but is about as cheap and flimsy as it could possibly get.

With the low horsepower on these smaller 10" saws, they are not really intended for re-sawing, except on small pieces. This is not a portable lumber mill. I recommend this saw for most small shop woodworkers who understand the frustrations I described. I do not recommend it for impatient and easily angered personality types. Images in this review. Although all 3 are very similar to each other, I decided on the WEN because of its added features.

I have several WEN products. They tend to offer more features than their competitors, and they perform quite well. However, it has been my experience that some tweaking is necessary for them to work optimally. The box was a little battered but everything was intact inside. Assembly using the instructions was easy and without any problems. However, it was slow. I switched the belt to the high speed position and it helps speed up the cuts. Essentially, everything worked as described.

This led to slanted cuts on the vertical axis. Not much of a problem with thin or rough cuts of wood but it created problems with anything that had any thickness or needed accuracy.

Any serious resawing would be out of the question. Major problems appeared when I tried replacing the stock blade with a thinner blade.

|

Guard For Band Saw 40 Sharper Image Digital Tape Measure Model |

dj_ram_georgia

20.03.2021 at 13:51:29

sindy_25

20.03.2021 at 11:25:18

VUSALIN_QAQASI

20.03.2021 at 21:38:18