3d Wood Work Up,30 Minute Wood Projects Online,Diy Wood Sauna Video - Downloads 2021

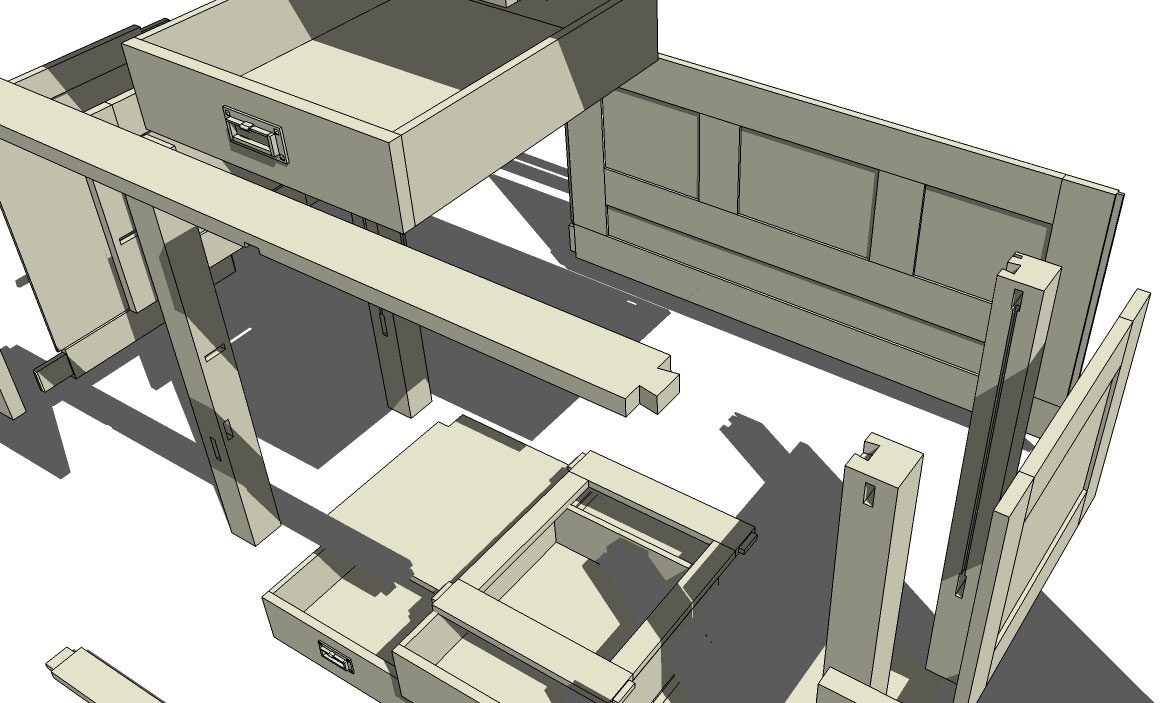

Moreover, this is a free 3D graphics software online you can easily download it for free. The software gets regular updates for bugs and errors and in terms of features, the software carries — rendering, modelling, sculpting, VFX, Video editing, pipeline etc. It is a simple but powerful 3d modelling software available on the web. Download: Blender 3D Software. With this software, you can visualize as many designs as you like without wasting a single piece of wood. When it comes to woodworking experts woodworkers recommends Sketchup because of its easy to use interface and outstanding features for creating woodworking projects.

With this free 3D tool you can design 3D models, electronics models, code blocks and other models. Website: TinkerCAD tool. Its an open-source and highly extensible free 3D CAD tool and its series of features and can even compare with commercial software like Inventor.

Moreover, due to the modular architectures this software invaluable in many 3D modelling industries like WoodWorking. For example, with the help of this software, you can perform sophisticated simulations with having a hassle. The software can installed into following operating systems Windows.

Mac and Linux. Download: FreeCAD software. Meshmixer is outstanding free 3D modeling software for woodworking its supports multiples features 3D CAD designing such as you can custom printers and also use your printer software at the same time. Wings 3D is an advanced subdivision modeler for 3D model designing. It is also an open-source 3D CAD software with multiple features for designing different types of 3D models.

It features a context-sensitive interface, configuration interface with hotkeys and much more. Allow yourself at least half an inch or more in the distance between Wood Workshop Warszawa Instagram rings, which will be your wall thickness before you turn. You will need all the room you can get to fudge the patterns to make them look good and consistent in the final product so thickness now will pay off later, but not to thick or you will be making a plate not a bowl, right?

A quick word about parting. Wear your face shield. I use at lease two parting tools. One used for cutting the other in water cooling. This process generates a lot of heat. The sharper your tools are the less you will have a problem with heat. Watch constantly for bad joints and pieces that want to spin off bad joints can be treated with super glue on the spot.

Most of the time bad joins will reveal themselves more through the sound of the turning than sight. Turn slow, to tops. At this point you also have another alternative for cutting and harvesting rings, namely the band saw. You can if you choose put your band saw bed at a 45 degree angle and cut your rings that way instead of on the lathe. Of course you will have the entry scar from where you entered the particular ring but with gluing that can be dealt with.

It is a much safer, easier way to handle it although you will have the glue line from entry. I have used both ways and both have worked, still there are many ways to accomplish the same result; this is just the one that I currently feel the most comfortable with.

So here is what we are looking for, rings at a 45 degree so that the bottoms will fit on the top of the previous ring. Well for one thing you would have a blast, but remember you can only swap if you have been very attentive to each angle being 45 degrees and each cookie the same diameter and each ring in that cookie the same interior and exterior diameter and thickness both on the bottom and top. It is a lot to keep track of but here is where is pays off, complex patterns that are simple to form.

And what is the down side? What if you mess up a bowl different from the rest? Still you can rotate the patterns of the same cookie and they will fit to get a great look or try a random look. Worst case you can always give it to your mother in law, right? The turning from here is pretty basic. After just make a jig to flip and finish the bottoms away from the chuck mount look and more into the bowl bottom look, sign and date always even if it is a sharpie.

Your kids will appreciate it. The pics below are how my 6 turned out. Notice that with close inspection the patterns are not perfect but merely close. The practice bowl never made it to finishing. It is in more pieces than I care to mention scattered across my shop floor the victim of bad joinery. Oh, by the way I found this glass inside this vase during the turn. The scrapes and waste of this style are almost more fun to play with than the original concept.

Creating these designs is probably the most difficult wood work I have ever done. It is not in the turning but creating the material. I might spend 8 to 10 hours creating material that takes 30 minutes to turn. Consistency is also a large problem along with minimizing cumulative error in the material.

Glue up jigs are a must to keep the glue up from sliding and moving on the triangular matterial. Running 8 inches of material through 4 inches of table saw blade is a scary proposition. So heads up, if you go down this path you need to be extra carefull. Be sure and count the of fingers you have before you start. After, if the number is in any way different be sure and tell your wife she was right. An easir solution would be a 12 inch table saw but who can afford that, right?

The problem lies in cutting on the bias. A 45 degree is nice, less is better. You can see this in the material next to each which are the scraps of the original material.

These vessels are created with 4 pieces with 2, 45 degree cuts each. Allowing the 4 piece construction is trickier to get perfect seams and connections perfect which gives you the most dramatic look but the longer slices of the pie make the slopes and curves more dramatic. Of course because you are turning a quarter of the round by the time you come to the end you are into end grain, augh as can be see in this close up. But using a more end grain sensitive matterial unlike this walnut can get you the best of both worlds as with the butternut.

The benifits with the 4 piece construction are well worth it. You can get the owl eye look or LA freeway look and and combination thereof depending on how you align the joining ends. It requires experimentation for sure. I often was suprised with what waited for me inside the wood by way of design. Try it and see if you can have as much fun as I have. From Wood bin to Wood Art. The Amateur woodworkers play ground. This Site is dedicated to the millions of basement and garage, amateur wood shop owners who have always wanted more than the 'Honey Do' list.

Let this play ground of wood shop fun improve your creative enjoyment. Designed by. For some time now I have wanted to try this design. It is a spinoff of the Multi Generational Diamond Lamination technique demonstrated in my last post.

All the basics laid out there are essential. Please do not take this post independently. Use the previous one and graduate up. As with the other it is simple but not easy. Be willing to get it wrong a couple of times before you take it to your critics. The most important aspect of this technique is without a doubt the jig. With this design you need the ability to cut at This cut is very dangerous.

Most miters go to 45 maybe 50 degrees but you need the full Also pay special attention to the vertical 90 degree angle of the blade to the bed of the saw or you will be making a shallow bowl. I feel the table saw is your best bet.

Here you can see my jig. You will have to come up with your own but be aware you will need stops on the front and rear to keep the jig from moving too far into the blade.

Also keep in mind your fingers are very close to the blade so spend the time to make a jig that protects them, slides even and true. Also, be sure and stop the blade from moving before you move the material forward to load up for another cut. Nothing can move, not the material that is loaded or your cut-off. Make sure everything is clamped down tight, and be sure and count your fingers before you start and write down the number. If the number is different when you are finished you may have to go upstairs and tell your wife she was right.

Humor aside, there is nothing more confidence building than the proper jig which gets you and your fingers away from the blade. This is the goal. Nice clean half diamonds made by flipping the material for each cut. Now we feel more comfortable and will move into the more Wood Work Holding Tools For Mac expensive material. Notice the jig holds everything in place, even the cut-off, and uses an oak stop block so each cut-off is uniform in length.

I have had problems with less than that taking my material out of square simply by the force of the hold down clamps. Substitute more clamps for less pressure on them to avoid this. When I do my wood working lectures one of the most liberating aspects I talk about is safety. A little bit of safety goes a long way toward enjoying and having fun in your shop.

The opposite is also true. If you are unsettled or unsure of your new jig or equipment — Do not use it. Just stop. Take the time to increase your confidence level by getting a friend involved or taking a course through your local wood working store. Do whatever it takes to turn this liability into an asset. You can always send me an email and I can help point you in a direction.

Here it is forming diamonds. For me, the previous post on MGDL diamond technique is safer and easier, but this one affords you the possibility of including vertical runs of laminate within the diamond. Also notice how the grain orientation is better with this I have fun with all these shapes before I commit myself to a particular look and bring out the glue bottle. Here is another look you can get by simply sliding everything to the left or right.

When I was making many backgammon boards I had lots of leftover elongated triangles so I glued them up. The more pressure I put on them the worse it got until I had glue on me the dog and a 2 foot diameter mess that sloped to the left horribly.

So I let it harden up only to find one of the most curious and wonderful pieces I have ever produced. I turned it into a clock whose hands turn clockwise but the wood oriented counter-clockwise. Believe it or not the more I stare at it the more my hair grows back.

Do not be afraid of making mistakes as they sometimes are the gateway to unique and wonderful creations and ideas. Look at these last two pictures closely and see if you can pick out the subtle differences in design. When it comes to clamping these, less is always more.

If you do not have a tight fit do not force it. Stress in wood is a lot like stress in people, it will find its expression like water flowing through the path of least resistance. Work on better joinery rather than forcing a bad fit. Forced fits, generally speaking, crack within the first year or so. I use a lot of rubber bands. You should not need more than that. If you do, try hose clamps, they work great. Graingers sells them in the 16 in diameter but lots of smaller ones put together also work, in some applications even better because you have multiple tightening positions around your circle rather than just one.

You will be putting together the stars in one glue up so be careful not to damage the points with your clamping. One way to protect the fine corners of the diamonds is by using caul blocks cut from scrap to distribute the clamping forces to the broad faces of the diamonds rather than the sharp points see picture below. Also using rubber bands as clamps gives you a bumper so to speak if you choose to use other clamps. After the star we begin to add on the walnut triangles.

The great thing about this project is the design possibilities are endless. You could use squares or 2 separate colors of triangles in both a horizontal or vertical orientation as you build out around your central pinwheel design. It is important to remember you are adding as you go. If you let glue dry in the trough of the diamond it will act as an obstacle to your next fit-up. I use a tooth brush as you see here to remove any wet glue so that when it dries I have a nice fit for my next piece.

So there you have it, another fun, fun, fun 3D-ish design that has many different applications. Weather a lazy Susan, cutting board, trivet, hot pad or wall decoration, it will get you lots of Oooohs and Ahhhhs through the years. Trapezoide becomes a Triangle becomes a cutting board.

Here is another design on the right, with many of the same characteristics in the tumbling block design. I call this design the tumbling triangle design although I am sure it has many names. Since many of the techniques are similar I will spare you a lot to the comontary and try to move through the project with more pictures and less chit chat.

If done correctly the above traiangles can be glued in place with the help of rubber bands. Remember to clean off any excess glue from the exterior of the triangle so the next one will fit snugly along its side after the glue has dried. Notice there are two rows. These rows may look the same but believe me they are not. To make the final product you will need equal amount of triangles both your first one and then its opposite. These are like gloves.

They are identical except they are opposite or face one another. Experiment with your shapes and you will get it. I assure you that none of your wifes friends or their friends friends have anything remotely like this in their kitchens.

For some time I have been experimenting with designs in wood art. The 3D concept is a fun project and although it has particular challenges, they can be overcome with practice and determination not to mention a lot of wrongly cut pieces in the scrap bin. As you can see this design is made up of diamonds. These diamonds take some time and lots of scrap to get just right. You will need a very accurate mitre box or cutting tool to get these just so. Proceed only after you have a very tight uniform result or you will be chasing gaps and spacing in the glue up and never get a good result.

Start with pine before you get into the expensive stuff. Here you see I have chosen ash, brazilian walnut and brazilian cherry.

|

Horizontal Slot Mortiser For Sale 64 Woodworking Jig Making Supplies |

Elik_555

27.12.2020 at 11:39:58

RAZINLI_QAQAS_KAYFDA

27.12.2020 at 16:49:19

NEITRINO

27.12.2020 at 22:16:23

665

27.12.2020 at 23:55:35