Using A Router For Wood,Mallet Hammer Wood Zones,Free Standing Wood Planers - Easy Way

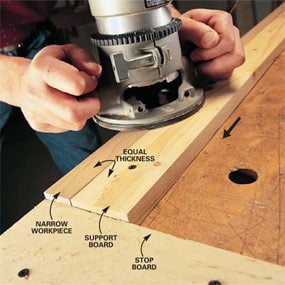

And you should, of course, as a standard protection procedure always Router Bits For Woodworking Library wear eye protection when using tools. Safety is the main consideration when using a router as the tool cuts with an un-guarded, high speed rotating blade. Preparation before use is essential. Always make sure the wood you are working on is securely fixed in place before you start routing.

Unsecured items can move hence damaging your work and potentially harming you as well. Wood router tables can be used with medium and larger sized plunge and fixed based routers. Router tables vary in sizes from stand-alone to bench-top. The router is mounted upside down on a special plate that fits into a hole cut into a table top.

Otherwise, it operates the same. The advantage of this is that it makes more accurate cuts and expands the use of a router. The most important Best Rated Routers For Woodworking 00 part of the wood router are its router bits. Without them, the router is basically just a motor that rotates. When you purchase router bits, you should keep an eye on the profile of the bits pictured below. If the bit is dull, chipped, excessively burned or has any other defect, it should be sharpened or replaced before use.

The cutting bit of a router rotates clockwise. For this reason it is important to hold the router firmly and router the piece from left to right, so that essentially the wood being cut is being fed into the cutting bit.

If the cut is being made along the grain it should be effortless and smooth. When a cut is made and cuts across the grain, place a piece of scrap wood at the end of the wood so that it does not blow-out splitting of wood at the end of the grain.

Unless absolutely necessary, never router wood from right to left with the cutting bit rotating clockwise. When beginning to work with a piece of wood, begin by making a series of several shallow cuts.

This will keep the wood from splintering and allow for greater control of the router. Making several shallow cuts will also compensate for inadvertent gouges made into the wood by the router. Sometimes this occurs because of knots or uneven pressure on the router.

Making a final cut, slightly deeper than the cut where the gouge appeared, will seamlessly remove the gouge or any burn marks caused by the router. The first thing to keep in mind is to use really sharp and top quality bits.

We say top quality because cheaper bits will likely have cheaper carbides, meaning that the bit may not cut as cleanly as a better bit would. To give you the best results, always purchase the best bit you can reasonably afford. This poses a bit of a problem when you need to route end-grain. Start cutting the ends first. Any tear-out on the edges will be cleaned up when you cut the side edges with the grain afterward.

If you find that routing the entire profile that in one pass of the router causes splinters, try making a few passes removing only a little bit of stock at a time. Your bit will be much less likely to grab and tear if it has less to grab onto. The speed at which you pass the router bit through the wood is important as well. Every experienced woodworker expects the possibility of a tear-out. Many router kits include a single motor that can be interchanged between a pair of bases for versatility.

There are hundreds of different types of router bits when one considers all of the shapes, shank sizes, bearing tips, and other options. However, there are ten basic router bit shapes or profiles that when used Wood Router For Sale Canadian Tire Events in combination, can shape a great many complex edge profiles.

If you're just starting and don't know what router bits profiles you'll need, these 10 bits are a great start. A proper edge profile requires the bit to turn smoothly as it is being applied to the edge of the stock. The first step to ensuring that the bit turns smoothly is to make sure it is installed properly in the router's collet. It's important to install router bits properly, no matter what shank size bit you're using.

A router's motor can rotate the spinning bit at speeds of up to 25, rotations per minute rpm , which is more than rotations per second. Most routers have the ability to adjust the motor's speed, as you certainly wouldn't want to use such high speeds with every bit and every routing application. If you take a long hard look at the router bit selection at any fine woodworking supplier, you'll find that the bits are available in two different shaft sizes, or shanks, that fit into the collet of a router.

The tool makes it easy to cut the two most common types of dadoes: a through dado, which runs through both edges of a surface, leaving the ends open; and a stopped, or blind, dado, which ends before one or both of the cuts meets the edge of the surface.

A rabbet is a recess or groove cut into the edge of the wood, usually used on the back edge of a cabinet or the sides of a bookcase. Rabbets are also used to create door and casement window jambs, and can be used with a dado to form a strong joint. Most routers can accommodate a variety of rabbet bits, which cut the grooves to the desired width.

Routers can be used to cut patterns, grooves, and designs across multiple pieces of wood. Routers can also be used on flat pieces of wood to trace intricate designs or lettering. Routers can be used with a jig to cut space for recessed door hinges or lock faceplates.

Recessed hardware yields a more finished appearance and smoother operation. The 10 Commandments of Buying the Right Tools. Clever project ideas and step-by-step tutorials delivered right to your inbox each and every Saturday morning— sign up today for the Weekend DIY Club newsletter!

|

Do It Yourself Garden Stones Lyrics Router Box Joint Jig Plans 12 |

naxuy

02.09.2020 at 23:25:45

123321

02.09.2020 at 17:47:26

SERCH

02.09.2020 at 10:32:48

streetracer

02.09.2020 at 16:10:34