Pattern Makers Woodworking Vise Key,Tools To Cut Circles In Wood Office,Build A Box Mod - PDF Books

We noticed you are accessing from Canada. Change to Lee Valley Canada website to see content specific to that region and the best shipping options. This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article.

Once all of the images have loaded, select the print option again. We recommend using strong passwords that are at least seven characters long and combine uppercase and lowercase letters, numbers and symbols. An Error has occured, please try again.

The patternmaker is responsible for making the wooden pattern for the main object and the "core boxes" that are filled to form the cores. Mahogany is often used especially on small patterns like these because it is easy to carve, holds details, and is fairly dimensionally stable and augmented with glued-up sections to make it even more dimensionally stable.

While small, the pattern for this nozzle has two cores and a follow piece, making it a pretty complicated mold. The main nozzle is precision turned and glued together with the nozzle outlet that was turned and carved separately. The two spuds on the top of the main pattern are extra and and hold the two cores in place. The first step in casting the nozzle is to put the nozzle flat on a board with the undercut piece.

The undercut piece was carefully carved and fitted to fit over the rear fin and rounded hose bottom. Sand gets poured over the entire object and rammed tight. Then the mold is turned over and the undercut piece is removed. Both the pattern and undercut pieces have little holes on the bottom so the foundry can screw in a rod and lift out the two parts. With the undercut piece removed, sand is pour unto the space created and over the bottom of the nozzle.

The two halves of the mold are separated and the red main pattern is removed. What we have is now a negative imprint of the nozzle in the sand. While this is going on, a clay-based core material is forced into the two core boxes. The box coxes are also mahogany, glued up for stability. The two halves have registration pins drilled through from the bottom so they the halves align properly. The insides were turned and then a bit of wood glued in. The spiral channel then carved to make the shapes.

In order to get a good stable glue joint, the grain of the built up piece is aligned with the outer material. In the pictures you can also see the layout and scribe lines used to do this accurately. The second core for the inside of the hose part is made the same way, with a glued up block and three registration pins. The core tapers in at the end so that is registers with the mold and that tapering suggests to me that the entire groove was carved by hand.

Unfortunately I don't have any cores. By the way, the box in the back of the group picture is what I kept the pattern and parts in since I think I left the hot pot behind. Since the 's this type of patternmaking has been done less and less. Wooden patternmaking is largely a thing of the past. This project would be 3D printed directly from a CAD system. Sand casting is still done, but the patterns in many cases are CNC machined from plastics, styrofoam and other synthetic materials, not wood.

The huge range of specialty patternmaking tools - such as long patternmaker's scribing gouges - are no long made. Scribing gouges differ from carving gouges in that carving gouges are shaped with an arbitrary "U" shaped curve. Scribing gouges were readily available in specific curvatures in with both the bevel on the outside out-cannel or on the inside in-cannel.

Join the conversation. Thanks for the trip down memory lane, so to speak. In addition, the bolt may tighten or loosen its grip on the turrets depending on the direction in which they turn. I hope to overcome this shortcoming by purchasing a spring washer capped by a bronze washer to act as a thrust bearing under the bolt head.

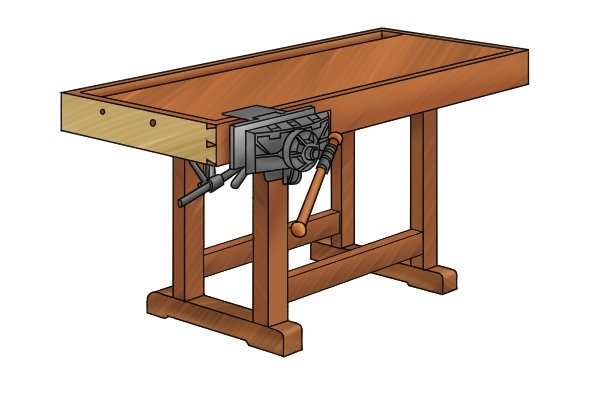

Apparently, I am not the first to notice this issue. After the threaded stem is tightened into the turret base, the user caps the assembly with the lock nut. The lock nut allows for a moderate swivel friction without the annoying loosening up of the turrets. The common way to connect the vise to the bench is via a long stem screw that penetrates the bench through a hole. Part of the required out-of-the-box assembly work is to thread in and tightened the main vise stem screw to the base.

I found that a 12mm wrench is the most appropriate size to use. I wish the maker had paid more attention when mounting and securing with a spring pin the handle onto the screw. To install the plate, just loosen the mounting nut and insert the base under the original steel base. Although my vise arrived unbroken, the turret base of the massive vise punctured its way out.

|

Shark Hd5 Review Uid Pocket Hole Jig Lazada Sg Wall Cabinets Knobs And Pulls Dress |

xoxanka

28.01.2021 at 14:16:51

RIHANNA

28.01.2021 at 19:44:14

ETISH

28.01.2021 at 23:36:39

AngelGirl

28.01.2021 at 21:12:48