Metal Lathe Cutting Tools Near Me,Rosewood Raw Wood Veneer Jack,Workshop Woodworking Bench Question,Pocket Hole Screws Ireland Uk - Downloads 2021

We're testing the functionality on this listing for future integrations with parent listings on YP. From Business: We enjoy meeting the needs of our customers. Our Flexibility accommodates production requirements for immediate delivery or release orders to smaller quantities…. From Business: For more than 60 years, Ferguson has earned a strong reputation among contractors, builders and plumbers across the country.

We are the largest distributor of…. Exellent customer service, tools are phenomenal. Not high pressure but a low pressure type of conversation. I like the great parking lot, and large store, and great selection of kitchen appliances like refrigerators. They Are great, Easy to deal with, kind, honest, helpful, respectful, good listeners! As a past customer, I recommend them, and, So will you I….

Fixed my Wacker and generator both run better than ever. Price not too expensive either. Thanks guys. External Profiling. Internal Grooving. Grind- Your- Own. Internal Threading. Face Grooving. Internal Profiling. Cast Iron. Hardened Steel. Heat- Resistant Alloys. Stainless Steel.

Tool Steel. Right Hand. Left Hand. High- Speed Steel. SiAlON Ceramic. Cubic Boron Nitride. R8 Taper. AL- 4. AL- 5. AL- 6. AL- 7. AL- 8. AL- AR- 4. AR- 5. AR- 6. AR- 7. AR- 8. AR- BL- 4. BL- 5. BL- 6. BL- 7. BL- 8. BL- BR- 4. BR- 5. BR- 6.

BR- 7. BR- 8. BR- C- CT- CTL- D- E- EL- 5. EL- 6. EL- 8. EL- ER- 5. ER- 6. ER- 8. ER- FL- 8. FL- FR- 8. FR- GL- 8. GL- GR- 8. GR- TSA- 5. TSA- 6. TSA- 8. TSC- 5. TSC- 6. TSC- 8. TSE- 5. TSE- 6. TSE- 8. CCMW- CDHH- CNG- CNGA- The figure shows H.

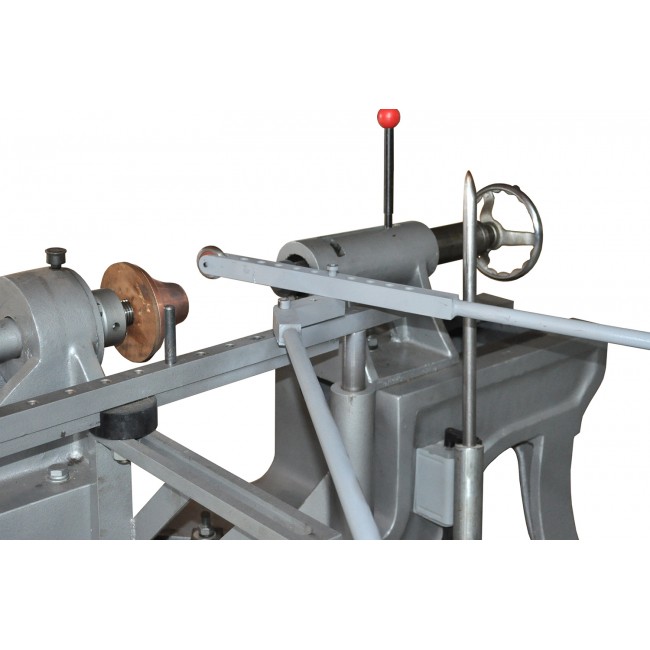

The length of the tool is , ,, and mm and the nose radius varies from 0. Grooving tool is similar to a parting-off tool illustrated in the figure. An ordinary lathe turning tool may sever the purpose where a copying attachment is used to reproduce the form of a template.

Flat forming tools are made of two types:. These tools have their cutting edges ground to the shape of the groove, undercut, or thread to be cut. Flat dovetail forming tools have a wider cutting edge corresponding to the shape desired. Dovetail end of the tool is fitted in a special tool holder. These tools are preferred in production work as a very long cutting surface can be used resulting in longer tool life. The centre of the tool is set slightly above the centre line of the work to provide an effective front clearance angle on the tool.

The tool will rub against the work if the centres are of the same height. Regrinding is done by grinding the flat only.

A boring tool is similar to a left-hand external turning tool so far its cutting edge is concerned. The tool may be a bit type inserted in a boring bar or holder, or forged type having a tool shank.

The figure shows an H. A boring bar is made of mild steel with slots or holes cut into it to accommodate the tool bit which is locked by an Allen screw. The amount of projection of the cutting edge of the tool from the centre of the bar determines the finished hole diameter of the work. The bit is generally inserted at right angles to the centre line of the bar for boring a continuous hole passing from one end to the other end. The bit is set at a single to the axis projecting beyond the end of the bar for boring a blind hole.

The counterboring operation can be performed by an ordinary boring tool. The tool cutting edge is so ground that it can leave a shoulder after turning. A counterbore having multiple cutting edges is commonly used. Undercutting or grooving tool has a point and form of the cutting edge exactly similar to the form of the required groove.

Clearance angle is given at all the sides of the tool. For the recessing groove cutting edge, the longitudinal feed is employed. The front clearance angle depends upon the bore of the work. A parting off tool is normally forged and used as bits for cemented carbide tipped tools. Parting off tool is made as narrow as possible to remove the minimum of metal.

The width of the cutting edge range from 3 to 12 mm only. The length of the cutting tool which inserts into the work should be slightly longer than the radius of the bar stock being machined. As the tool penetrates deep into the work, clearance is provided all around the tool cutting edge to prevent it from rubbing against the work surface. As the tool is purely ended cutting it has no side rake slight back rake is provided on the tool to promote an easy flow of the ships.

A right-hand tool is shown in the figure. Is that which is fed from lathe bed, i. A right-hand tool is formed on its left-hand end when viewed from the top with its nose pointing away from the operator.

The left-hand tool is shown in the figure. Is that which is fed from the Left to the right-hand end of the lathe bed, i. The left-hand tool is used for left-hand thread cutting operation or turning operation which leaves a shoulder on the right-hand end of the workpiece.

A left-hand tool has its cutting edge formed on its right-hand end when viewed from the top with its nose pointing away from the operator.

|

Diy Pen Pal Kit Review Benchtop Bandsaw Reviews Uk 13 Bottom Mount Cabinet Drawer Slides On Pdf 9 Band Saw Blades Quote |

GRIK_GIRL

10.12.2020 at 17:19:49

Aylin_05

10.12.2020 at 23:45:12