Making Pens On A Lathe 60,Carbide Cnc Router Bits 55,Best Cast Iron Router Table Top Jp - Reviews

Your workspace is the thing you should always keep in mind. You must not be looking for a wood lathe that fits in your toolbag. So, analyze the area in your workshop and get the pen turning lathe that fits in that comfortably.

If you are frequently moving the machine from here to there, then look for the lightweight options. You should also know your budget boundary. The best woodturning machine may even come with a hefty price tag. So, if you are not thinking about the payday loans, then always check the price of the tool before making your mind.

The midi or small lathes, in most cases, come in affordable price ranges. Whether you are buying a pen making lathe for your hobby, professional life, or just for enthusiasm, getting the right tool is the most effective factor for your success. And I am sure with the help of the above shortlisted best midi lathes and the buying guide; you will get the real value for your money. Which lathe will you buy for your pen turning project? Which other types of woodworking job will you do on that?

Share your inputs in the below section. Your email address will not be published. Save my name, email, and website in this browser for the next time I comment. Notify me of follow-up comments by email. Notify me of new posts by email. Lorena Kent I am a carpenter by profession.

So I come across different types of job needs and have handled various types of tools for that. In all the machines that I have used, I found a lathe machine one of the most exciting units. It helps to correct and make the desired shape of an object such as a pen. My passion for this machine led me to create this website dedicated to the different types of lathe machines. I hope you will enjoy it and find it useful. Related Articles.

August 12, July 14, Is Ashley Iles a good company for this or should I be looking for something smaller? Honestly, I pretty much just make my own tools now, but when I buy a lathe tool off the shelf, I go to Woodcraft rather than Rockler. They tend to have better prices and a little more variety.

I like Rockler for a lot of things, but they just seem to be a bit light in the turning department. Something ele to keep in mind is that if you can, try to buy individual pieces rather than the sets.

The sets will get you going, but they always have some shortcoming, so you end up replacing them in the long run anyway. Sounds like if you just start with a gouge you should be good to go. Just take some extra stock and try turning some pen shapes.

Don't bother with the tubes or anything: you just want to see if you can make the shapes. That should give you a good indication of whether or not you need more tools.

Actually, thinking about it, the other thing that may be useful is a thin parting too. It does tend to make a few things easier, but you could probably get by without it for a while. That's it. The advice I was given was to get a bowl gouge first because you can do spindles with a bowl gouge but you can't do bowls with a spindle gouge. I still prefer to use the bowl gouge over the spindle gouge for pens though.

I am a fan of the Woodcraft European Deco pen kits I have seen some of the other ones where the shaft is a fixed length I have done LOTS of things on this mandrel because I can shorten it's length my moving more of the rod into the headstock I would think the fixed length ones would be too limiting.

Word of advice: do NOT over tighten the tailstock onto the end of the mandrel You can also jack up your live center pretty good by making them too tight. I have only been turning pens Making Pens On A Lathe Yellow since April of this year and have turned over pens now. Here is a link to the easiest pen finish I have ever used.

Oak is not a very good wood to learn on. It is very open grained and requires that the grain be filled to give a nice finish. It also is a rather "plain" grain. I have made some pretty oak pens, but they were from areas with knots or other highly figured areas like crotch wood.

Most of my pens are turned from "found wood" Local firewood piles are a good source if you live where there are a lot of hardwood trees growing. Here in Arizona I turn a lot of mulberry, chinese elm, mesquite, texas ebony, olive, even some paloverde. I also frequent the local specialty wood store and pick up small pieces of offcut exotic lumber in pretty grain patterns.

I would suggest you get some slimline kits to learn with. I get my slimline kits from Woodturningz. One thing you really need to do is get a grinder to sharpen your tools. They have to be sharpened frequently. I use a Porter Cable rpm grinder with a Wolverine jig. If you Making Pens On A Lathe Zero are going to be doing about 25 pens, you would probably be better off buying a couple of "bulk bags.

Keeping the kits similar helps cut your tool requirements down, like mandrels, bushings, tools, and kit parts. If you can get to a Woodcraft near you for a turning class, I'd recommend it.

The experience alone will help speed up your confidence. I took a class on the Circuit Board pen a while back, and learned quite a bit. I only used three tools, and spent quite a bit of time with the micro mesh pads. One thing I was cautioned on was that the micro mesh sanding foam pads were not required for wood pens, but acrylics and resin pens absolutely require them. As for pen presses, you don't absolutely need one.

You can use your drill press carefully , a couple of the handscrew clamps, or a variety of other methods. The benefit of the press is that it is consistent. Depending on the type of kit you get, you will need a drill bit of a certain size. Most of the kits I've seen at Woodcraft take metric sizes, and seem to be either 6, 7, or 10 millimeter. And bushings vary depending on the type of kit you get.

Unless you are extremely frugal and very good with your aim while turning, I'd recommend getting two or three sets of the bushings at the beginning. Nothing sucks more than going out to buy another kit, forgetting what bushings you already have, and purchasing one, only to discover it's what you already have.

Be sure that you vary the pens for everybody. I know this should be obvious, but a variety of pen blanks will keep it from feeling like you just purchased a bag of pens at the discount store. A drill press with at least a 3" quill stroke and something to hold your blanks while you drill them is always handy For just starting, the HSS lathe tool set from Harbor Freight is fairly inexpensive and surprisingly good quality.

I have that set and a set of Sorby tools and I keep them all together. I don't notice who's logo is on the handle, they all work equally well. I find different materials like different tools Also, Sorby makes a tool that is sort of a scraper and sort of a skew I forget what they call it You'll need a grinder or something to keep the tools sharp.

I use a WS and it works great with the see through disks. I started out with a cheap Harbor Freight lathe the smallest one they had , the cheapest lathe tools I could find, a small benchtop drill press, a single mandrel, 7mm kits and matching drill bit and bushings.

Cranked out a pile of nice pens with that cheap setup. I learned what better tools and whatnot do and have since upgraded, but it doesn't require a huge investment to start up. I use a chuck sometimes if I am turning smaller parts. Its easier to just take the rod off the mandrel and chuck it up as deep as needed rather than drill out wood and try to make properly sized spacers. The only other advice I can give is a I am looking on rockler and woodcraft websites and they seems to have to styles of mandrels.

Does anyone know the difference between the 1 and 2? How do you know which one will attatch to your lathe? Generally you can tell by checking the manual or spec sheet that comes with your lathe, or finding one online.

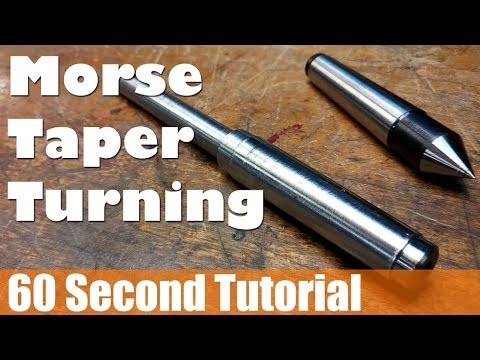

What kind of lathe do you have? If it's a modern one odds are that it will be a 2MT Morris Taper. That is the larger one. By the way, some folk seem to pronounce it as "Morris" taper, but it's "Morse" named after Stephen A.

Morse who also evidently invented the twist drill. Take a peek at Wikipedia My lathe is a cheapy, i think the brand is Tool Shop, its a menards specail. I didnt want to put a lot of money into my first lathe because i wasn't sure how well i was going to do at it.

I didnt want to sink hundreds of dollars into it if all i was good at making was tooth picks. I havent been able to use it much since getting it so i will have to dig the manual out as see if it say. After reading Alan Z's link below i am a little worried.

Thank you for the link, After reading through it i am a little worried now. My lathe is on the cheaper side of prices not sure if it has anything to do with it but my "head stock" i think its called doesnt look like the pictures in that wiki post. Mine has a small point in the center with 4 even smaller evenly spaced points around it. I believe that piece is threaded onto a shaft but all that comes out of the box where the motor and pullys are at is a threaded shaft maybe inch or inch and half long, is that bad for me?

I'm not sure how much you're wanting to invest in each pen, but PSI has some good deals going on right now. There's also quite a few good sales going on right now on kits which might help you give some higher quality pens without spending your whole christmas bonus. As for finish, imho this depends on the quality of pen you're giving. For my slimline pens, I sand up to , burnish, throw on a coat of tung oil, and seal it with one quick coat of CA, buff, and I'm done.

I don't see the point in spending more than a few minutes on a pen that's only worth a few dollars. Again, the quality of pen dictates the quality of finish.

I'm not trying to push PSI over any of the other stellar online vendors out there, I just recently came across these good deals and wanted to share the wealth. And I'm def not an authority on the subject, but I dabble. I have some recent pens posted in my gallery if you want to take a look to see what I'm talking about.

Any chance you can post a photo? Hopefully what you describe as a center point with 4 other points is actually a drive center that's been inserted in the headstock. On the opposite end of that shaft where it sticks out the left end of the lathe, is there a hole in the middle? If there is, then normally you would get the center out by inserting a rod in the hole and tapping on it.

If it's one solid piece though, that isn't going to do any good and I would guess there's some sort of adapter that goes on those threads so that you can attach things to it.

It's possible that the unit is so basic that it isn't meant to have other centers put in it, but I'd have to see it to know more. Is there any kind of model number or other info so that we could look it up online? My link. The part can be taken off and it came with a plate mount that i assume would be for turning bowls but it threads on too.

The MT taper doesnt not have threads right? I was able to unthread the drive spur and take it off but what it was on is just a solid shaft that is threaded as far as i can tell.

Does anyone know if there is some sort of adapter to go from a male thread to a MT? I was looking at this mandrel from Penn State and it looks like it has a threaded portion on it but i cant tell if it is the same type of thread. The thread on the lathe is pretty course. Anyone have this mandrel or know what its threads are? You can post now and register later. If you have an account, sign Making Pens On A Lathe Yoga in now to post with your account. Paste as plain text instead.

Only 75 emoji are allowed. Display as a link instead. Clear editor. Upload or insert images from URL. There are no registered users currently online. What do I need to make pens? Reply to this topic Start new topic.

Prev 1 2 Next Page 1 of 2.

|

Pocket Hole Machine Home Depot 12 Etam Yerevan Sign Into Spectrum Router 80 Diy Live Edge Wood Projects 500 |

mulatka_girl

22.04.2021 at 11:17:38

seymur

22.04.2021 at 14:45:23

zemerald

22.04.2021 at 20:48:49

AskaSurgun

22.04.2021 at 11:33:25