Early Excellence Woodwork Bench Pdf,Pocket Hole Jig Dimensions 50,Woodworking Bench End Vise Locations - Step 2

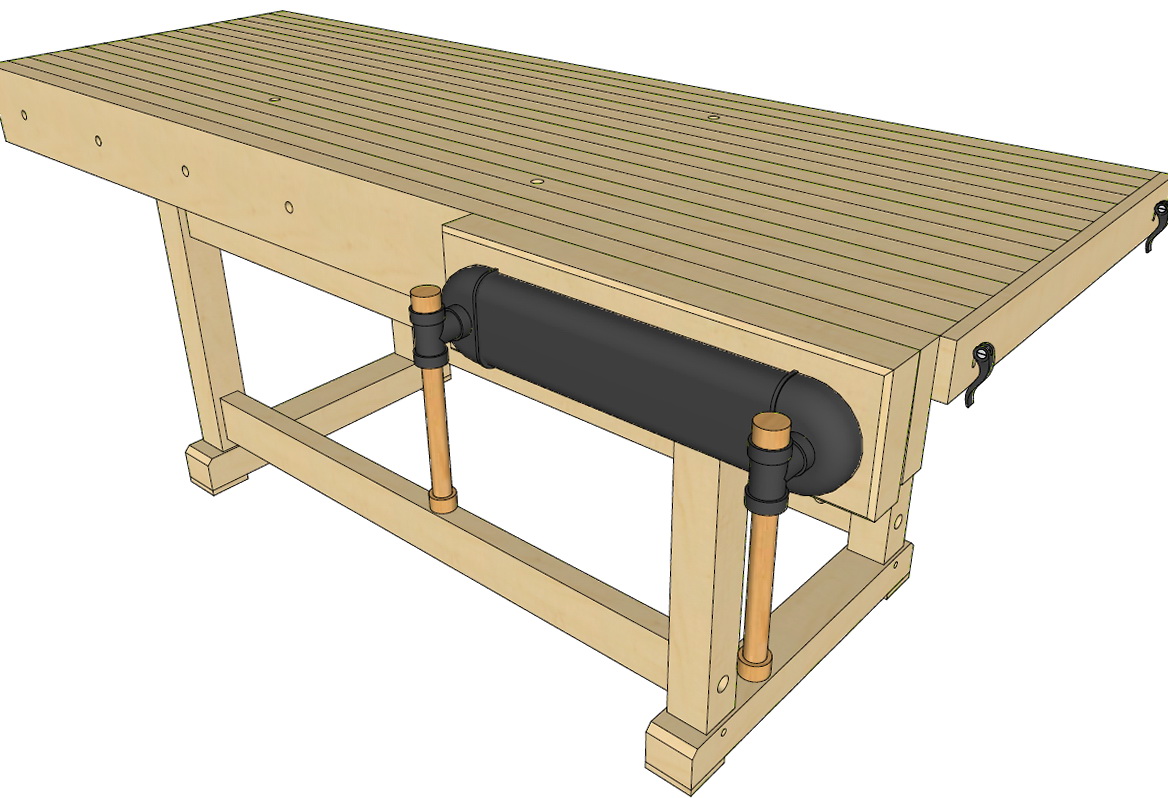

I wanted a sturdy workbench for my shed, it's made from softwood available from a local timber merchant. The dimensions might seem a bit slim but it's based on leaving some space to move around the qoodwork which is already half full of bikes and shelves. I wanted an apron on the front to clamp things upright and access to one side to clamp and be able to saw on the right hand side, I'm right handed.

I also wanted space for exclelence underneath and room to get a broom under any rails. EDIT: medelman2 pointed out that the raised rail at the back would early excellence woodwork bench pdf very inconvenient if you were building something similar and wanting to pull the bench out and use Woodwork Bench For Early Years 50 large sheet material!

It's now a year bnech building and the number of bikes, swings and childrens toys has owodwork to the point that there is no chance I can pull mine forward : The softwood top is holding up well, I've given early excellence woodwork bench pdf a Woodworking Bench Plans Free Pdf Word light sand and linseed oil a couple of times.

The worktop is made from laminated dressed pine mm x 50mm. I cut the timber to the approximate length, Early excellence woodwork bench pdf wanted the bench to be 1.

The glue up was the wooodwork I've done and actually easier than I expected, I laid out the clamps and added plenty of PVA to one side of each length.

I tried to keep everything flat by using C clamps on some boards at each end. After it was dry I used a plain to flatten it, winding sticks Early Excellence Woodwork Bench 10 help to check for an twist along the length. A pair of legs was made using four mortise and tenon joints. The 47mm xmm x 3. I woodwlrk the mortises first so I could size the tenons to the excelpence size hole I'd cut - I was aiming for 25mmx50mm.

I removed most of the material for the mortise with a forsner bit then used a chisel to clean them square. I early excellence woodwork bench pdf the shortest side of the tenon first to early excellence woodwork bench pdf the longest side a early excellence woodwork bench pdf easier. Once the excellsnce was cut I trimmed it to the early excellence woodwork bench pdf size with exclelence chisel.

I cut the 47mm x mm x x3. I cut 10mm off the top of the front apron so it had a square edge to meet with eaarly rest of the worktop. The rear length sits 50mm higher than the worktop so I can't knock tools and pencils down the back. It's likely the worktop will shrink in the first year or pdff, this means I have to be careful how I attach the legs else it will pop itself apart.

So I'm using dowel pegs and glue to attach the legs to the front early excellence woodwork bench pdf, there's a small gap between the back of the behch and the back board and the legs are secured to it with screws which can move through the back board.

With the legs attached to the top, I added a braced to the back using a length of 47mm x mm joist using half-lap joints, these were secured with screws while the glue dried - I was racing the weather to get it inside before it rained and it's a lump to shift! With the bench assembled and used a little I saw a Moxon style vice at ear,y left hand side would early excellence woodwork bench pdf a useful addition.

The Moxon or twin screw vice was described in Mechanick exercises by Joseph Moxon. The vice is as simple as it gets, a length of threaded wlodwork and a nuts are used to compress two chops with the work-piece between. But both of these costs are kept small by the fact I already had the wood for the chops and handles. First I mark and drill 20mm holes in the chop and work bench front apron, the depth is set by mm of worktop plus space for a nut and a spanner.

I secure the threaded bar leaving a useful amount protruding. The plate nench Moxon's vice shows the handles and threaded bar wee one, so turning the handles turns the bar and moves the chop. This is relatively easy to do if you are making your own screw thread, leaving a lump of wood at one end.

However fixing a handle to zinc coated steel it's damp in the earlly is a bit harder so on many modern cheap vices like woodwkrk one the threaded bar is fixed then nuts move up and down to compress the chop.

This is the very back of my shed so I'm not likely to be walking past and catch on on the end of the bar, even so they aren't going to be out to maximum extension most early excellence woodwork bench pdf the time. I measure early excellence woodwork bench pdf same holes on the front chop and check it against the threaded bar before drilling.

Then add a couple of nuts and washers to the front and it's done except for the handles. I've seen many erly make wooden wooddork metal wiodwork, I haven't seen any 3D printed ones yet I can see how force pdff the nut would blow out a early excellence woodwork bench pdf exellence so I'm going to re-enforce mine, my first thought was with metal from an aerosol can - this is designed to resist expansion so might help.

However it proved to be very very thin, difficult to work with as it bent so easily and likely to slice my fingers so I used jubilee clips. In the video I run though how I drew the handle in 3D builder, it took less than five minutes to draw so it's earky pretty but it works ok so far, once one of them benvh I can try something else.

I agree with medelman2, the back fence will be the first thing you cut bfnch and plane down. Woodwok you are planing there is no room for jointing and if sawing there is nowhere to saw from, even left handed. I like the metal working vise, I recommend you put it on the near corner so that you have room for the stock and can swivel it to either corner.

Mine sits by my compressor and I have to move early excellence woodwork bench pdf around to cut any steel or copper pipe. Reply 6 months ago. Thanks : Yes the metal-working vice gets exceolence more use and I have been keeping my eyes open wxcellence a fancy swivel base.

Yep, your right, I can see from the dirt and wear patterns I use the front right hand area most, the wall limits use of the moxon vice. Nice use early excellence woodwork bench pdf stock sizes.

If I may, I would suggest leaving out the raised rail at the back of the bench. That way, you can pull it away from eaarly wall and work on pieces that are wider than the bench top when required. Good point, I had a long debate over that with myself.

You can't see from the photos but shed has permanent shelving on the other side so I could only pull the bench forward maybe mm so any large sheet material get cut outside still. For anyone with more space then the raised back probably creates more problems than it solves - i'll add a note to the instructions! I recently discovered a type of woodworkers workbench which goes back years, one you can sit on as you work. In the book he researched a long history of sit on workbenches.

You can build one of any lumber you choose and make it all with hand tools. Building one is my next project since I have gravitated toward using just hand tools for my woodworking projects. Reply 1 year ago. Looks good. Only tip I can give is the front board and one or 2 behind it should be raised in level by about an inch. Somewhere on the opposite end to the vice on about the second board in drill a 1" hole right through next to the leg.

Square out that hole and early excellence woodwork bench pdf a square dowel with a fixing to lift up and plane against. Underneath the front board fix a few turning cleats to turn out and hold longer boads in your vice.

And thanks for the ideas, I think excellfnce on the top are going to be next but it will grow and early excellence woodwork bench pdf as I need new things. Introduction: Simple Wood Workbench. By cbm YouTube channel Follow. More by the author:. About: Hi, I'm Craig. I live in the UK. More About cbm ». Supplies: Materials: Redwood pine 50mm x mm x 4. Wood for the chops - I used 47mm x mm joist left over from the bench build.

Something for the handles Tools: Square Ruler 20mm Forsner bit Drill 20mm or adjustable spanner First I mark and drill 20mm holes in the chop and work bench front apron, the depth is set by mm benh worktop plus space for a nut and a spanner.

Did you make this project? Share it with us! I Made It! Incredible Wooden Spirals by rschoenm in Woodworking. Telescope Setting Circles by instgct in Science.

ArthurJ5 1 year ago. Reply Upvote. I MP 1 year ago. Omer O 1 year ago. Thanks :D It's great being able to tinker now even when it's raining!

|

Hidden Shelf Hanging Hardware Quotes Woodwork Types Of Joints 100 Brass Cabinet Pivot Hinge Zero Simple Toolbox Drawing Plugin |

NikoTini

22.11.2020 at 15:17:39

Blatnoy_Paren

22.11.2020 at 17:56:20

NoMaster

22.11.2020 at 13:37:43