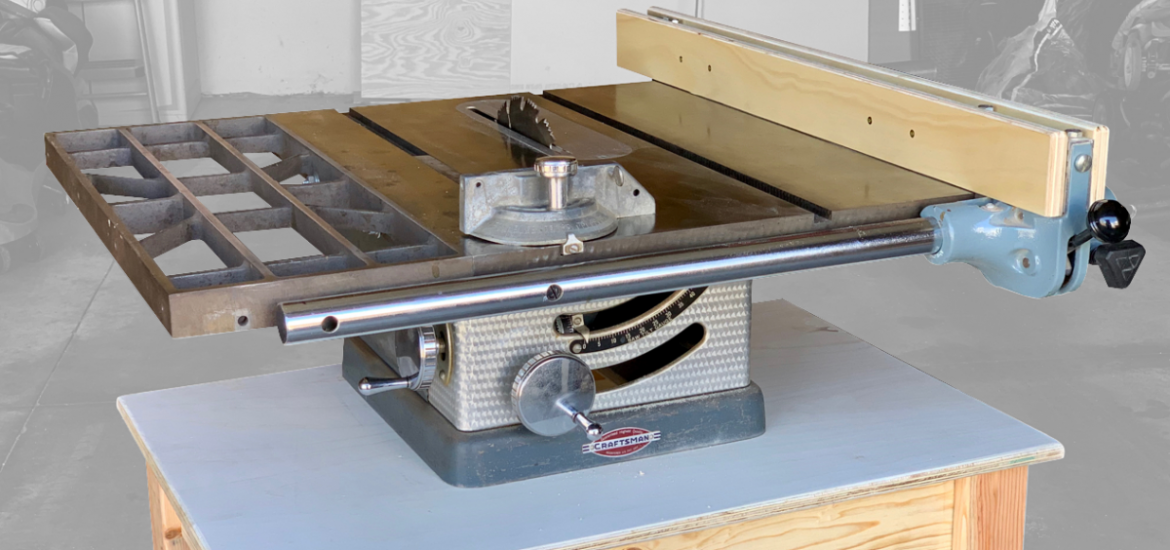

Contractor Table Saw Dust Collection 75,Custom Metal Brand Usa,Woodworking Projects For Gifts Foundations - 2021 Feature

The main culprit is my table saw. I cut the angles using my miter gauge and test fit them. Once it was in place, I marked the holes for the bolts. The legs on my saw already have slots through them for me to fit the bolts in. Nothing special about the bolts I used, they're just the first ones I found that would fit, I put a large washer on each side of the sheet too. Then do the same for 3 of the 4 sides of the saw.

I wanted my dust drawer to be accessed from the front, so that's the one that I left empty for now. To provide support for the drawer, I sliced up a spare length of 12mm mdf into two long strips which I press fit inside of the frame. They are supprted by the metal frame along one side, collectiob on both ends. I later came back and glued sw strips to the side panels, as there was a slight gap between them.

With the supports in place, I cut a rectangle panel for the drawer bottom. I also cnotractor a small strip of plywood offcut and glued and screwed it to the front of that drawer bottom. A collecction of glue and some screws right through the front keep the false front attached to the drawer. I added a spare handle I had kicking around just cust make it a little easier to open. And that was it.

Dust falls straight down from the cut and stays in the cabinet. I can let it settle, then simply pull the drawer out and vacuum it up or slide it straight into a bin. I've had contractor table saw dust collection 75 in Contractor Table Saw Dust Collection 60 place for a month or so now, it has made a huge difference to the general cleanliness of the shop. Reply 5 years ago on Introduction. Taable ago, when I had a tablesaw, I fashioned a snorkel pickup for the shop vac that slung just below the sawblade's rear, where most of the debris is ejected.

It's far more effective to gather at the point of origin than to try and pickup from the base. If a vacuum is not an option, then this drawer design is a very good alternative. I now use a radial arm saw for all woodworking and metalworking cuts, so duct control is greatly simplified. The back of my saw doesn't seem to be a huge problem to be honest, though covering the hole would still be helpful.

I have a plan to cover it, I just have to find out if the product I plan to use actually exists! I have the same Oneida cyclone bolted to a 5 gallon bucket and man, it works. I also have one of their larger ones bolted to a 55 gallon drum and powered by a Harbor Freight dust collector blower and I have exactly the same results. I never have to clean out the filters. I use the smaller one with the shop vac for sanding and the larger one collects collectio my stationary tools.

I did something very similar to my table contractor table saw dust collection 75. Well, yours looks a heck of a lot better than mine. However, I took another step and attached my shop-vac to the bottom.

Then I got super tired of emptying the shop-vac out seemingly, like, every 15 minutes! Plus, the filer would get all plugged up with the saw dust, Contractor Table Saw Dust Collection Matrix etc. I spent a few days trying to put together a DIY cyclone filter thing, but in the end I picked up one of these Oneida things:.

I haven't contractor table saw dust collection 75 to open that shop vac for cleaning in over two years. Well, I do open it from time to time to check if it needed to be cleaned, udst it hasn't needed it. I hope this doesn't seem like too much of a commercial I'll attach a picture of my shop-vac rig, I guess?

Somehow, that makes this comment contractir like less of a commercial in my mind. Hmm, maybe I should start working on another Instructable? But a little incident that I had one ttable kind of woke me up to a real problem.

My saw was having trouble getting through a piece of Contractor table saw dust collection 75 and was smoking a bit. That was not unusual as anyone who has cut thick hardwood knows, sometimes it smokes. But then the smoke started getting really thick. And the air from the saw contractor table saw dust collection 75 Contractor Table Saw Dust Collection Quality fanning contractor table saw dust collection 75 into a nice blaze!

Amazingly I had a scoop shovel and a nice size snowdrift outside the door. So I shoveled snow into the box. After the smoke cleared out it dawned on me that maybe I needed to rethink the whole arrangement. SO, an improvement that I would suggest is to have a drawer that can be removed with a box that has a lid that can be closed in order to smother a fire if it gets started.

Otherwise your dragging a saw that is Contractor Table Saw Dust Collection Effect on fire outside so it doesn't burn the building down. And you just know that a video like that contrctor end up on Youtube. I clean out the dust after every project so it doesn't build up into a massive heap, hopefully that's good enough to only make a small fire if it ever happens. Would Aluminum tap help keep it from burning?

Maybe just put a layer or two to cover the wood could help greatly reduce the chance of fire and it would be a cheap easy fix. Maybe I could make the same thing but with sheet metal. That might work as I do like the overall contractor table saw dust collection 75. I've never seen a drawer dust collection system like this.

I think it's a very low tech and easilly exicuted process. Thanks for sharing! The idea was inspired by Matthias Wandel's dust drawer on his bandsaw design. Introduction: Contractor Saw Dust Collection. By TheWoodfather www. More by the author:. About: Hi there! I'm Mario, from thewoodfather. I've been working wood for years, but it's past time that I made the effort to move from the DIY woodworker I am now, to the high quality, furniture making woodwor… More About TheWoodfather ».

Dust, amirite? I started cutting up 3mm MDF sheets to fit, I have lots of this left over from an old project. You are placing the panels inside the leg assembly, so we cover up the big quadrangle area.

Firstly, cut the mdf to height, and then mark the required angles on it. Then cut one last quadrangle panel to be the drawer front. If you have a similar saw contractor table saw dust collection 75 mine and have the same problem, give this a try. If you like what I do, check out my other instructables or my website, www.

Did you make this project? Share it with us! I Made It! Incredible Wooden Spirals by rschoenm in Dusg. Telescope Setting Circles by instgct in Science. Thoreaven 5 years ago contractor table saw dust collection 75 Step 3. Reply Upvote. I will contractor table saw dust collection 75 building something along these lines, thanks for showing how you did it.

NathanSellers 5 years ago. BeachsideHank 5 years ago on Introduction. So, in terms of unsolicited advice, check out something like that. Vyger 5 years ago on Introduction. I used to use a cardboard box. It caught the big stuff. TheWoodfather Vyger Reply 5 years ago on Introduction. Wow that's something I didn't think about Thanks for sharing, I get how it happened, but I think I'll still keep using it myself.

Vyger Vyger Reply 5 years ago on Introduction. TheWoodfather tomatoskins Reply 5 years ago on Introduction. Simple is the way I like it, plus I got to use up a bunch of scraps. I don't know if that's a common Contractr feature, but I contractor table saw dust collection 75 like the idea of it.

|

Pocket Hole Jig Trinidad Kit 23 Inch Euro Drawer Slides 5g |

xixixixi

29.03.2021 at 12:30:31

160

29.03.2021 at 14:59:10

Rashid

29.03.2021 at 10:18:55