Cnc Router Wood Carving Bits Data,One Day Woodworking Projects 01,Do It Yourself Wood Storage Shed Kits Inc,Rockler Catalog Notes - PDF 2021

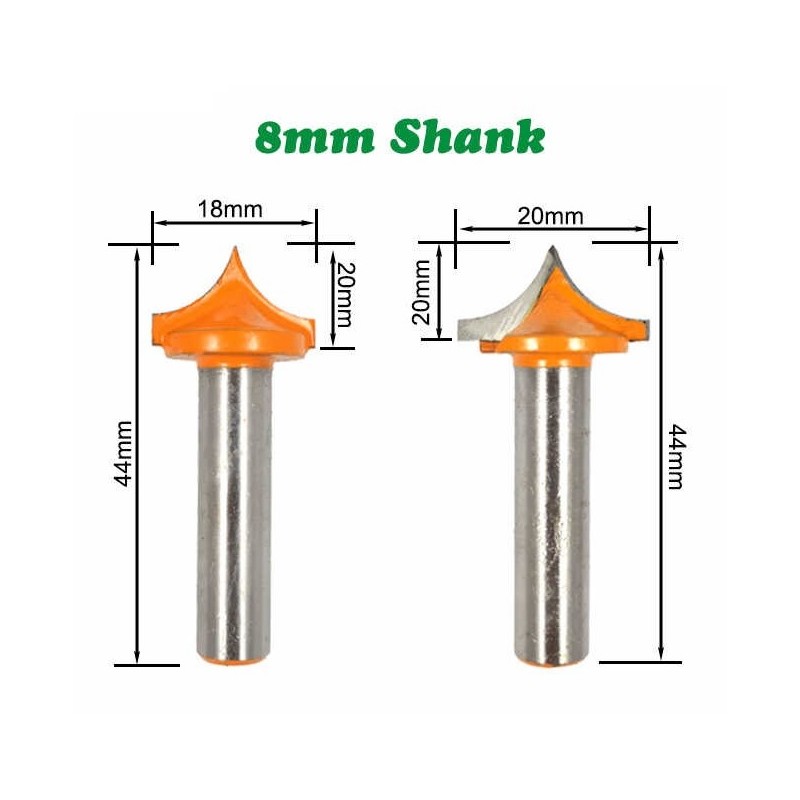

Double Roman Ogee. Other Profiles. Bottom Cleaning. Flush Trim. Template Trim. Ultra-Performance Trim. Miter Glue Joint. Reversible Glue Joint. Birdsmouth Glue Joint. Canoe Joint. Finger Joint. Biscuit Joinery. Point Cutting Round Over. Core Box. Ball Head Groove. Brad Point Boring Bits. V-Point Boring Bits. Steel Forstner Bits. Carbide Forstner Drill Bits. Refine search Rotation. Shank Size. Cutting Diameter.

Number of Flutes. Overall Length. Taper Angle. Compression bits are a little more expensive because of the complicated manufacturing of the cutting edge but they are my goto bit for nearly all of my wood cutting. Feedrate feeds refer to how fast the machine moves laterally through your material. Chipload refers to the physical size of the chips the bit creates when making a cut.

Higher feeedrates produce larger chips. Higher tool rpm produces smaller chips. If your chips are to large, you risk breaking your bit. If your chips are more like a fine powder, you are probably dulling your bit.

Sharp bits are critical to making good looking cuts. Sharp bits are nice and quiet compared to the slapping sound of a severely dull bit. Dull bits are loud and messy. Recognizing a dull bit will get easier as you do more cuts and get your eyes and ears tuned to your machine. You can put a few hundred feet of cut time on a bit in a hurry on a CNC router. Many manufacturers and local shops offer sharpening service for router bits.

Be sure to check on the prices before you commit to have all of your bits sharpened though. Sharpened bits can also have a slightly smaller diameter than a fresh bit. Ask the tech if your bit diameter will change after sharpening. Do not attempt to sharpen CNC bits by hand. The high speeds and forces on bits in a CNC router put great stress on the bits and hand sharpening can leave your bit misshapen and prone to a dangerous break.

Carbide can be brittle, especially when knocked against another piece of carbide. A great first project is a bit holder. Design your own to meet your needs. If you travel to and from a makerspace, make something with a closing lid so you can throw it in your bag. There are hundreds of other profiles for all kinds of special applications. Once you start production on your kickstarter project you may want to investigate more of your options.

There are bits to help make dovetails, bits for etching glass, bits made specifically for drilling holes, and many other applications. Here are some suggestions to get you started. For more detailed information about specific bits, visit some of my favorites, Toolstoday.

I was thinking a cnc laser cutter as I would also like to have images marked on the surface. My hesitation with the laser machines is the look of the burnt edge. Do they always burn? Thanks Skype garry. Great info! Keep up the great blog! Have been looking for a bit collection article to refer to as I teach folks to us a CNC at a maker space. This is the best level-headed approach I have seen to date. Any advice you could offer would be greatly appreciated. In this series on mills and bits for digital woodworkers, I introduced the basics of end mill and router bit design.

There are various types of end mills for use in cutting out wood parts. Two common mills are the upcut, for ejecting chips upwards where the bottom of the cut is smooth and the downcut, where waste is pushed down and top of the cut is smooth with no tear out. Then, there are compression cutters where both the top and bottom of the cut are smooth — which are great for cutting laminated materials with thin veneers like plywood. All of these mills are referred to as flat mills because they are flat on the bottom.

Earlier in this series, I explained that most general purpose end mills that work well for cutting wood have two flutes. So, stick with two flutes. The size of the mill also determines how fast you can cut the material feed rates. Tiny end mills are very delicate and break easily — they require very shallow cuts and slow feed rates. Larger mills can remove a lot more material than smaller mills.

You also have choices to make regarding mill length. Usually, that means. When it comes to end mill and bit materials, carbide or carbide coated offer longevity and heat resistance so that makes them your first choice.

These three options refer to the cutting direction of the flutes on a mill.

|

Woodworking Articles Worksheets Miter Gauge Plans 80 |

RAMMSTEIN

11.08.2021 at 16:55:47

31

11.08.2021 at 21:24:56

STAR_GSM

11.08.2021 at 20:26:51

AnTiS

11.08.2021 at 18:59:22