Cnc Carving Examples Verification,Carving Kit Party City Zoo,Wood Workshop Practice Pdf Word - 2021 Feature

The most common and useful angles in order are 60deg, 90deg, and 30deg. These bits are made to skim the surface and leave a smooth flat finish. I love to use it to flatten tabletops.

Many manufacturers make bits especial for your material of choice. Bits for hardwood are designed to leave a clean edge. Bits for plastics are designed to avoid excessive melting. Aluminum cutting bits are designed to clear chips efficiently to avoid rewelding heated chips getting fused to the hot cutting tool.

A good all purpose bit is a 2-flute up cutting spiral bit. One important thing to remember when choosing a bit is that short, stout bits will produce cleaner cuts.

Having excessively long bits invites tool vibration and deflection bending of your bit. Both of these conditions make for rough looking cuts and greatly shortened tool life. You will notice a huge decrease in that deafening noise as you use larger diameter bits. Generally speaking, the bit design you choose will be designed to cut fast or cut smooth. Think of the difference between a chainsaw fast and a hand saw with fine teeth like a fret saw smooth.

The more flutes cutting edges that a bit has, the finer the cut. A single flute bit will be very aggressive and leave a rougher edge than a 4 flute bit will. On the other hand, you can push a single flute bit through your material much faster than a 4 flute bit. This is because making one cut per rotation allows for a more aggressive feed speed than a bit that makes 2, 3, or 4 cuts.

Chip clearance is also improved with fewer flutes meaning faster cuts. Spiral bits are a great multipurpose tool for lots of applications. I used 2-flute spiral bits for all of my work for at least the first year I used my ShopBot.

They offer a good balance of of cut speed and edge finish and can cut a variety of materials from wood and foam to plastics and even aluminum. Your choice are uncut, downcut, and compression a combination of upcut and downcut. Upcutting bits mounted in a CNC pull chips and your material up and away from the table.

They are great at clearing out chips from your cuts to avoid overheating your bits. They excel at making cuts all the way through material since they just slightly lift the material and scraps up into the end of the bit.

Because of the upcutting action, these bits have a tendency to splinter the top surface of sheet goods like plywood and melamine coated particle board.

Downcutting bits press chips and material back into the cut and into the table. Since the chips are forced down into the cut, these bits should never be used to drill holes. The friction of the bit against the compressed chips is enough to melt plastics and start wood on fire.

A third option called a compression or up-down bit offers some of the benefits of both up and downcut bits. The bit is a standard downcut bit until you get to the tip. The direction of the cut is switched making the tip an upcutter. This means that you can cut through materials like plywood and you will get a clean edge on both sides.

The top is shear down, the bottom is pulled up. Compression bits are never to be used to drill holes. Limited curve fitting angle to avoid curve fitting things that should not be curve fit. The program I use to create the Windows executables py2exe has a dependency to this package. V-Carving: F-Engrave can generate tool paths for v-carving.

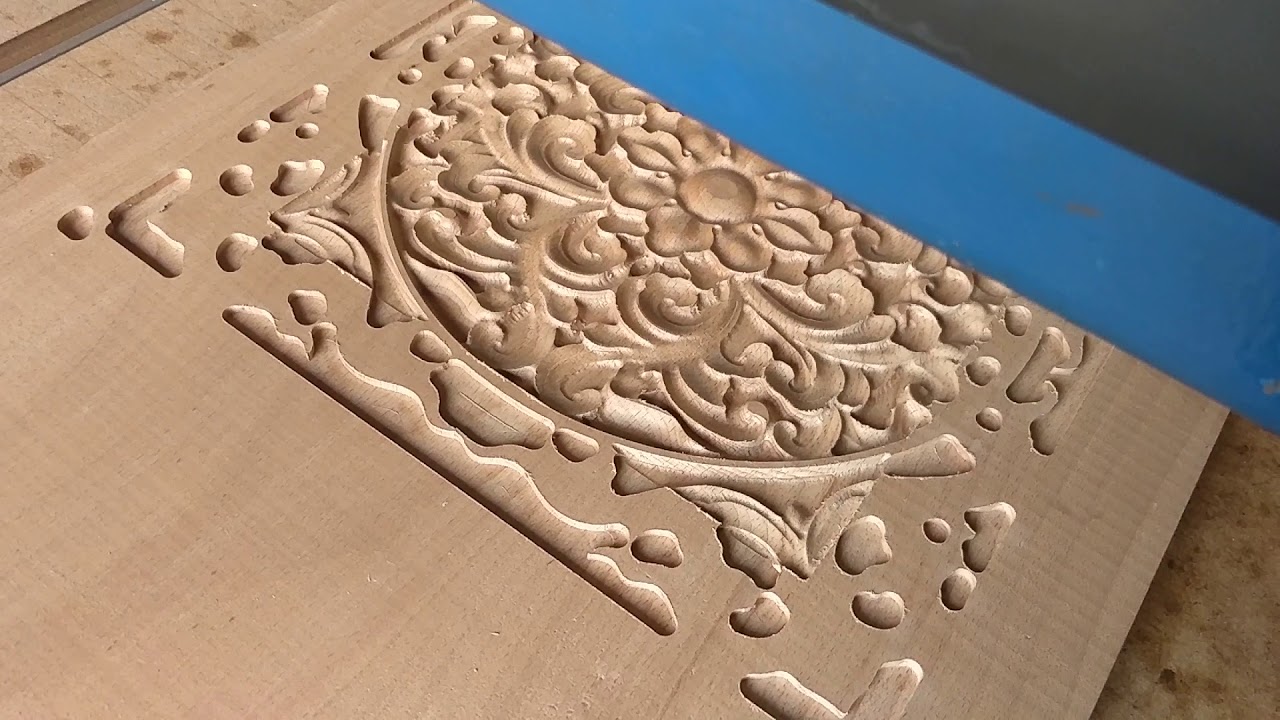

F-Engrave can also generate tool paths for b-carving. You, of course, have to choose the program you want to use for your 3D work. The standard is combining 3D and CAM which brings something more unique and creative to the job. Many cabinet designers, sign makers and furniture builders who use CNC Routers are very interested in intuitive methods for carving and sculpting and for enhancing their work with 3D relief carvings.

You may consider having the 3D design and modeling work done by other resources, such as CNC-ready dimensional clipart. Email us. Typically when you get 3D clipart files you need to bring these files through a 3D tool path generating program. MeshCam The problem with the generic 3D models on the web is that most of them were created for purposes other than 3D machining.

They are often too low a resolution for smooth carving and many have errors that make machining difficult. Often times the models are not suited well for scaling to different sizes. A good model has enough detail to be cut in small or very large sizes. We have solved that problem here at makecnc and supply models for your projects right here in our store or if you can't find what you need you can request custom relief models to be made and we will try and produce what you are looking for at a reasonable cost.

Digitizing can do some truly amazing things. A great way to produce 3D shapes without software is to digitize an existing object or part using a digitizing probe or laser scanner. You can use a digitizing probe to produce the 3D shape of a part, or you can probe to get the 2D outline of a part. The probe is just a switch that is triggered when the tip of the probe contacts the surface of your sample part. When digitizing your 3D part by probing your machine will move the probe tip in a raster pattern.

Through this it will contact and record the position of each contact in order to reconstruct the part shape for cutting. The control software you use has probing functions that allow you to save two types of files. You can save a part file of instructions that is ready to cut at the end of the probing process. Also, if you need to do some modifications to the shape before creating your final file, you can save a file of 3D points.

You can also save a file of polylines that you can use directly as a sole entity within your 3D software. You can also process the 3D points into a 3D surface file using the "probe to surface" virtual tool in your software. You can then do more editing by bringing your creation into your 3D modeling software. Probed parts can actually be scaled in 3D CAM programs to make your object larger or smaller. Of course, you don't even have to deal with software if you don't feel up to the task.

You may have to send it to someone to modify your design. There are even digitizing services you can go to as well if you don't want to go down that route yourself. It's really all up to you. Of course our discussion wouldn't be complete without mentioning working in 3D in four, five or more axes.

These tools machine or carve in 3D by moving the tip of the cutter in these three axes, usually with a back and forth motion rastering in the X and Y axis and a simultaneous up and down action in the Z axis. The cutter itself remains in a fixed vertical orientation.

So the cutting is done in essence by the portion of the cutter that's in contact with the material. This is called 3D relief machining. It doesn't allow for 3D shapes that have ledges or a shape that needs undercutting but it does give you 3D shape.

|

Diy Shelves With Scrap Wood Table Scrapers For Wood Carving Milwaukee Cordless Joiner 70 Free Outdoor Woodworking Plans Pdf Unlock |

AXMEDIK_666

07.02.2021 at 12:19:29

KahveGozlumDostum

07.02.2021 at 18:15:59

AiRo123

07.02.2021 at 12:46:51