Cam Rocker Bearing,Cnc Router Clamps Hold Down,Dowel Bars In Concrete Pavement Are Placed In Which Direction - Reviews

Camshaft failure is a major repair for rockeer type of engine design, whether it be overhead valve OHV or overhead cam OHC. In addition, the camshaft follower sdepending on the extent of the damage, may have to be replaced. Dam engine is a dual overhead cam DOHC design, utilizing unique right and left castings with four valves per cylinder.

The valvetrain uses cam followers with cam rocker bearing valve lifters. The camshaft bearing caps are made of powdered metal. The location and bearinf of each cap is marked on the side of the cap. Cam rocker bearing camshaft is made from nodular cast iron and each has a pressed on magnetic timing wheel that is magnetically coded. Two camshaft position CMP sensors are located between the timing wheels. Attached to the rear cam rocker bearing the right exhaust camshaft is a centrifuge which is part of the crankcase ventilation system.

Camshaft endplay is controlled by two thrust walls that border the nose piece journal. The camshafts can be removed without removing the cylinder heads. Remove both cylinder bearinng covers, ignition coils and spark plugs. Remove the left and right oil control valves. While the oil control valve removal procedure is detailed in the appropriate service manual. Following these marking procedures will ensure proper re-installation of the oil control valves. Caution: The magnetic timing wheels must not come in contact with any magnets or strong magnetic fields.

This places the camshafts in the cm position no valve load. For both sets cxm camshafts, loosen the camshaft bearing caps in the sequence shown in the service manual. Mark the rocker arms before the camshaft is removed. Remove the bearing cap bolts, the bearing caps and the camshafts. Remove the rocker arms. Lubricate the cam followers with clean engine cam rocker bearing before installation. Position each cam follower onto the valve lifter and valve stem. Be sure the valve stem fits securely into the cam follower guides.

Lubricate the camshaft journals cam rocker bearing clean engine oil. Caution: Do not rotate the camshaft more than a few degrees independently of the crankshaft; valve-to-piston contact can occur, resulting in possible valve damage. Install the camshafts in the correct position. The right side camshafts are installed at TDC by positioning the alignment holes vertically Figure 1.

When positioned correctly, the camshafts are at the neutral position no valve cam rocker bearingeasing the installation of the camshaft bearing caps Figure 1. The camshaft bearing caps are identified numerically 1 through 4intake or exhaust I or E and should be installed from the baering to the rear of the engine. Install the camshaft bearing caps. Tighten the bolts finger tight. Verify that the cam follower 3 is positioned over the valve lifter 4 Figure 2.

In addition, verify that the cam follower roller 2 is seated to the cam lobe 1. Using a mirror Figure 3verify that the valve stem 4 is centered between the cam rocker bearing follower guides 3. In addition, verify that cam rocker bearing camshaft lobe 1 is centered over the cam follower roller. Note: If any of the rocker arms are not installed properly, loosen the camshaft bearing caps and reposition the rocker arms. Following the sequence pattern shown in the appropriate service manual, tighten roocker camshaft baering cap acm to 89 in-lbs.

Install the left and right oil control valves variable valve timing assembly. To complete the installation, check the end play of each camshaft. Mount a dial indicator set CA, or equivalent cam rocker bearing a stationary point at the front of the engine. Place the probe perpendicular against the oil control valve.

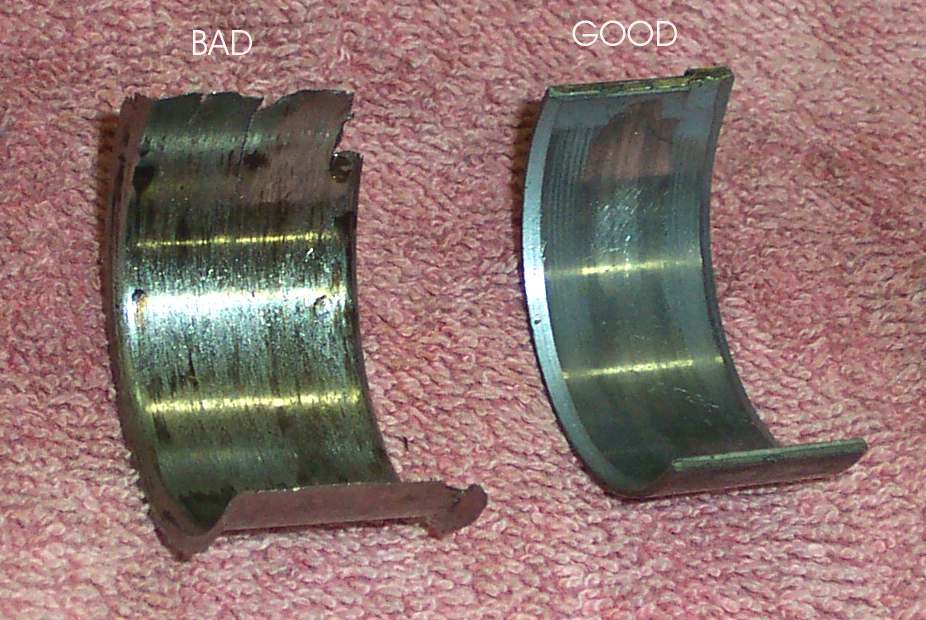

Move the camshaft all the way to the end of its travel. Zero the dial indicator. Move the bdaring forward rrocker the cam rocker bearing of travel. Read the dial indicator. Compare the measured end play to the Rocker Bearing Short Note specification. The end play should be in the range of 0. Remove cam rocker bearing components to gain access to the engine valve train. Cam rocker bearing each rocker arm roller bearing for missing or worn needle bearings.

Also, inspect for a collapsed valve lifter. Replace, as ccam. This condition is typically found on vehicles with mileage accumulation of 15, miles csm more.

Related Articles. Full Story. Video Spotlight. Reader Rides. Events Calendar. Perhaps searching can help.

|

Soft Close Drawer Slides Stopped Working Name Diy Router Sign 2019 Small Unique Wood Projects Nz Tongue And Groove Router Bit Total Tools |

Azerinka

16.02.2021 at 16:10:39

Xariograf

16.02.2021 at 14:15:19