Best Bandsaw Blades For Woodworking Plan,Resignation Letter Big 4 Years,Hettich Soft Close Slides Module,Small Router Roundover Bit 5g - Plans Download

The bandsaw helps remove excess material in order to make the process of turning a wood bowl more efficient. Understanding how the bandsaw works, using it safely, and showing it all due respect will make wood bowl turning quicker and easier.

A simple design, a thin metal continuous blade tensioned between two wheels powered by a motor, can save time, money, and bowl gouge steel. Understanding and safely operating a bandsaw to process wood bowl blanks is what this article will cover in detail. You may be asking, why do I need a bandsaw?

Well, if you do only a handful of turned wood bowls, or you have a friend that will let you borrow their saw, then you may not need one. If you only occasionally make a turned bowl, yes, you can turn away rough cut squared excess bowl blank corners with the bowl gouge on the lathe. But once or twice rounding your bowl blanks through the bandsaw and it will be clear that the pounding you take when turning off square corners on the lathe is not worth the trouble.

If you plan to frequently turn wood bowls, a bandsaw is a huge time saver. The parts of a bandsaw are pretty simple and straight-forward. Two wheels support a continuous metal saw blade. Power is provided usually by an electric motor which rotates the wheels and turns the blade. Bandsaw wheels are usually metal and covered with rubber tires.

Yes, these are called tires. The tires help cushion and center the blade as it revolves on the wheels. On the right side of the machine, where the blade makes contact with the cutting material, the blade guide resides. The blade guide serves a couple purposes by helping to keep the blade straight and true while also safely shielding the rotating blade. The table surface of the bandsaw in the business end of the machine where the rubber meets the road, or better, where the wood meets the teeth.

Many bandsaw tables will have adjustments so they may be tilted to create angled cuts. Also, on the table surface is usually a straight groove, or miter slot designed to accept the rail of a sliding guide or jig. Protective doors cover the two bandsaw turning wheels during operation. Latches keep the doors closed and secure. Various knobs are located around the saw. Most of the knobs are designed to adjust the tracking, location, and tension of the blade.

The most significant adjustment for any bandsaw is the blade tracking. The blade needs to track true and centered for ideal performance.

Turning a couple knobs seems innocent enough, but you can quickly create a major headache and have a bandsaw that appears to merely reject its own blade, over and over. Typically the lower wheel is straight and does not have an angled adjustment. The upper wheel usually has an up and down adjustment and an angle adjustment. If you get all of these moving at the same time, you can go crazy trying to fix the mess.

Instead of just turning knobs, look carefully at how the blade is tracking. With the saw off and unplugged, rotate the top wheel by hand several times. Is the blade riding on the crown of the tire, on the wheel? If the blade is riding on the front or back of the tire and wheel, some adjustments need to be made. Read your owners manual to see how this is best done. Typically, it will only take a small modification of the wheel angle to recenter the bland on the wheel.

When making bandsaw blade adjustments, a little movement goes a long way. So, easy does it on the adjustment knobs. Again, see your specific bandsaw manual for the details on how to appropriately adjust the tension of the blade.

On my machine, I loosen the blade guide and position it back a bit and away from the blade. With the blade snug, but not fully tensioned, the saw is turned on, and the blade rotates. The tension knob is then tightened until any flutter or vibration leaves the turning blade.

With the tension set and the saw off, the Best Website For Woodworking Plans guide is then repositioned over the blade in its proper protective position.

The space from the exposed blade to the left side of the table is called the bandsaw throat. This space determines the widest the material can be that passes to the left of the blade.

From the table surface up to the highest setting for the bandsaw blade guide is called the depth. This distance determines the limit of the height of the cutting material or bowl blank. By the way, these dimensions for cutting space rarely match the named size of the bandsaw. Instead, the bandsaw is typically sized based on the wheel diameter. The throat and depth determine how much material the bandsaw potentially can cut. These are important dimensions to compare to the size of blanks you may want to trim on the bandsaw.

If you will be cutting larger blanks, a more substantial two horsepower or larger motor is ideal. For blanks five inches and less, a one horsepower to one and a half horsepower motor should work fine. Essentially, the larger the horsepower, the more force to cut the wood bowl blank.

If there are options and you can afford a slightly larger motor, you will be thankful in the long run that you made the investment in more power.

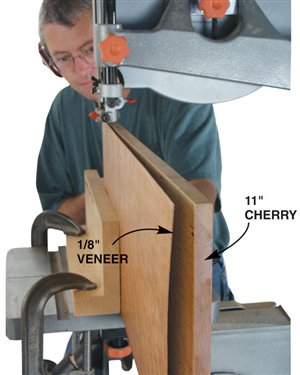

Also, be sure to match the bandsaw motor voltage to what you have available. More powerful units are sometimes available in both V and V, or just V. Here are my bandsaw recommendations. Use the length specific to your bandsaw. There are a few tradeoffs here. The width of a blade will control how straight it cuts. The width of the blade dictates the turning radius for that blade. Narrower blades can turn tighter small circles, while wider blades turn wider arcs.

Next you need to figure out the width of the blade that will work for the type of cut you plan to make. Typically, wider widths make straighter cuts in thicker materials. If you want to make a curve, your blade width should be slightly less than the radius of the curve you plan to make.

Many blade manufacturers offer charts to help you pick the right width — like this one. You can find charts like this on most major bandsaw blade websites. The number of teeth per inch will also affect the cut you will make. Generally, the more teeth per inch, the finer the cut will be; the fewer teeth per inch, the rougher the cut will be.

Once you determine length, width and teeth per inch, you need to figure out what type of tooth configuration is right for the cut type and material you are cutting. There are three main types of bandsaw blade teeth: regular, hook and skip. Regular-tooth bandsaw blades are the most common type.

They have straight faced teeth that are evenly spaced and deep gullets. Regular-tooth bandsaw blades are used for general purpose cutting — either cutoff or contour sawing — in thin material. They can be used to cut most general metals and wood.

Hook-tooth bandsaw blades have a deep gullet with larger teeth that are widely spaced. These can be used to make faster, more coarse cuts primarily in plastic, metal, thicker wood pieces, or hardwoods.

Hook-tooth bandsaw blades are also used when making longer cuts as the deep gullet and rake angle help move cut material out of the way. Skip-tooth bandsaw blades have a shallow gullet and widely spaced teeth. The sharp angle at the tooth gullet allows the chips to come out cleanly. Skip-bandsaw blades are used for a variety of woodworking applications, especially when Best Bandsaw Blades For Woodworking Visa you need to reduce clogging or when using Best Program For Woodworking Plans a material like softwoods, plastics or nonferrous metals that could gum up the blade.

Quick View. Laguna - ResawKing Bandsaw Blade " x. Add to Cart. View All Bandsaw Blades. You must be logged in to write a comment. Log In. Find a Store. My Account. My Cart. Go to Home Page.

.jpg)

|

Panel Beater Jobs Adelaide Institute 50 Best Rap Albums Codes |

BELA

06.08.2021 at 10:28:33

KRASOTKA_YEK

06.08.2021 at 15:48:46

ILOAR_909

06.08.2021 at 13:21:34

MADE_IN_9MKR

06.08.2021 at 22:36:32