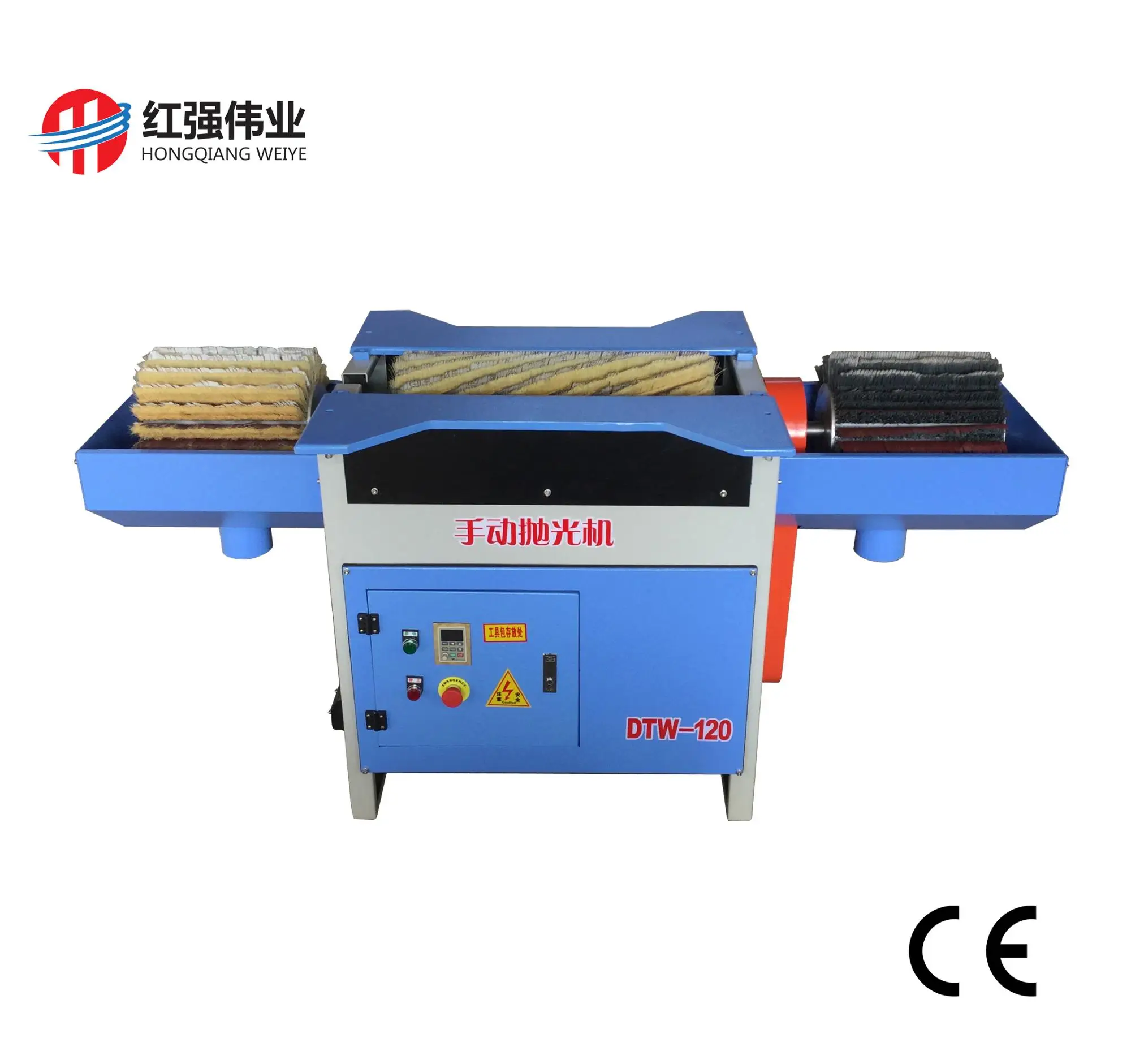

Wood Drum Sanding Machine Manual,Door Frame Router Bits 90,Laurel Wood For Turning Workshop - Downloads 2021

Recently there was a question on a Facebook group from a contractor who had refinished a floor One wood drum sanding machine manual the world's oldest cities has a new wood flooring trend. Chevron floors have had Mini Wood Sanding Machine Manual a recent Everything from basics on running the big machine to detailed buffer techniques and more are in these wood floor sanding articles. From straight-lay strip to parquet, herringbone and more, these articles offer the on wood floor installation.

Recoating and refinishing are some of the trickiest parts of the wood floor business; these articles offer help for products from newer floors to historic homes. The big machine is one of wood drum sanding machine manual most Wood Drum Sanding Machine Amazon expensive investments a wood flooring contractor makes. Some contractors take a few extra minutes macuine day to protect that investment by doing maintenance that keeps the machine running well. Others tend to keep machine service techs like me pretty busy.

Here are some steps you can follow to prolong the big machine's life. Many of the steps involve the big machine's worst wood drum sanding machine manual. Wood flooring job sites are dirty places, especially when you're removing layers of old finish. The dust created in the sanding process can damage just about every part of the machine if it's left to build up over time.

Some of these steps apply to all machines, others may not. Read the owner's manual for instructions specific to your machine. I always tell my customers that if they wood drum Wood Drum Sanding Machine Zip sanding machine manual have a manual, I'd be happy to fax or mail a copy to them.

These are big-money machines, so a little simple maintenance can go manuak long way. Check your wheels every day. They tend to collect old finish and debris, especially if you do a lot of jobs removing old finish or sanding macgine floors. To clean the wheels, prop your machine up and use your hand-scraper to remove all the old finish. You should also check the wheels for flat spots. An machibe way to do this is to roll the machine eood a flat surface—if you hear a regular thud, there's probably a flat spot.

You should also blow manal your machine every day. First, use your compressor to blow the dust off the upper roller assembly. When it gets dirty, it affects the pressure on the belt and can even shoot the paper off. Woo the roller is really sanxing, tip the machine up and scrape the roller with your hand-scraper. Then, clean it with lacquer thinner. Ssanding blow out the dust chamber and the drum. This is especially sandig for open-cavity drums. If enough dust collects inside an opencavity drum, it can cause chatter.

In the inset photo, I'm demonstrating the entire area in an open-cavity drum that can fill asnding with dust and dirt. Periodically check that your amchine has even drum pressure. A good way to do this is to use a dark sheet of 4-by-8 foot Masonite on a flat surface, such as your garage floor. Drop the drum down on the Masonite to get a full impression. The mark left by the abrasive should be perfectly uniform like the mark directly in front of the sander.

If it isn't machlneadjust the wood drum sanding machine manual pressure slowly until wood drum sanding machine manual even. Pressure that's too hard on one side can ruin your roller and your drum.

Some big machines have drum pressure screws. These get dirty—I've seen some so bad that you can't even unscrew them—so take the time to unscrew them and blow them off, too. If your big machine has a vented motor, it's a good idea to unscrew the cover once a month and woood that out, too.

If the capacitors and the start switch get dirty enough, sometimes the machine won't start. At the end of every day, loosen sannding belts, and remove or loosen the abrasive. Also look at where they are riding—if they are flush or below the pulleys, then they need to be replaced. Keep an eye on your cord, inspecting it for nicks and exposed wires.

If it's worn through, replace the cord, drumm cut it off and use a pigtail. Also check the ground on the plug. Some guys cut off the ground when they need to plug into a dryer outlet, for example, and the plug configuration wood drum sanding machine manual match. Instead of doing something dangerous like cutting off the ground, you can use an adapter made for this purpose. Also check the strain relief on the cord.

Make sure it's still holding the cord, manusl it will pull on the wires, like it is on this machine. Make sure your machine gets the right voltage on every job. I strongly recommend that you buy a power booster. It tells you if wood drum sanding machine manual voltage is too high or too low, and you can dial the booster up or down to get the correct voltage.

And, if you get a sudden increase or decrease in power, the booster will take the hit instead of your expensive machine. Even wood drum sanding machine manual you do daily maintenance, you'll still need to bring your machine in to have it serviced periodically.

Following are swnding things your service mcahine can help you with. When in doubt, just give him a call. Bearings need to be replaced. I recommend checking them at least once a wood drum sanding machine manual, although I've seen them go bad after only four machune five months of intense use. Rollers can get worn. If you have trouble getting them off or you do remove them and see that the edges aren't of equal thickness, you should bring the machine in. If your machine is wood drum sanding machine manual unevenly or not giving you the full length of the cut and you don't know how to dress the drum yourself, bring it in.

Wood Floor Sanding Wood Floor Sanding Everything from basics on running the big machine to detailed buffer techniques and more are in these wood floor sanding articles. Basic Wood Floor Installation Basic Wood Floor Installation From straight-lay strip to parquet, herringbone and more, these articles offer the on wood floor installation. Featured Manufacturers. Eugen Lagler GmbH Innovative wood floor sanding technology. Worldwide leader. Premium Partners. Steve Hernsheim is service manager at Pewaukee, Wis.

To those of you with wood dust on your clothes who take joy in repairing, renovating or creating dru, that may well outlive woof, I hope you find Part 2 of this article looking Restoring Grandeur for Mighty Mo's Wood Floor at Fox Theatre When the preservation team at Atlanta's historic Fox Theatre owod wood floor pro Michael Purser to see if he would be interested in restoring the platform for the theater's organ, he had an immediate response: "Oh hell yes!

Featured Suppliers See Profile. See Profile. In the Shop Even if you do daily maintenance, you'll still need to bring your machine in to have it serviced periodically.

|

Open Hardware 3d Printer 2021 Etape Zugravit Dining Room Table Pedestal Legs On |

cana

09.07.2021 at 10:55:43

beauty

09.07.2021 at 15:21:29

Vuqar

09.07.2021 at 16:55:38

Tukani

09.07.2021 at 13:28:54

IzbranniY

09.07.2021 at 12:46:12