What Metal Lathe Tools To Use 90,Woodworking Classes Phoenix Project,Cast Iron Dining Room Table Legs 80 - How to DIY

Shank Width. Shank Height. Material Grade. Shank Type. Insert Shape. Overall Length. Tool Bit Code. Tip Radius. For Insert Shape. End Relief Angle.

Insert Code. CCMT- Shank Diameter. Groove Width. Side Relief Angle. Insert Style. End Cutting Edge Angle. Side Rake Angle. Back Rake Angle. Inscribed Circle Diameter IC. View catalog pages Send Cancel. How can we improve? Lathe Tools. Carbide-Tipped Turning Lathe Tools. Diamond-Tipped Turning Lathe Tools. High-Speed Steel Cutoff Blades.

Carbide-Tipped Cutoff Blades. Face Grooving Lathe Tools. Curve-Cutting Lathe Tools. Form concave or convex edges on a workpiece. Round-Shank Boring Lathe Tools. These are the smallest boring tools we offer. Square-Shank Boring Lathe Tools. Internal Profiling Lathe Tools.

Contour the interior wall of a hollow workpiece. Lathe Tool Sets. Boring Lathe Tool Sets. Lathe Tool Holders. Cutoff Blade Holders. Secure square-shank tools to a lathe. Boring Lathe Tool Holders. Quick-Change Lathe Tools and Holders. Indexable Turning Tools. Turning Carbide Lathe Tools Used For Sale France Insert Holders. Parts for Carbide Insert Holders. Screws for Carbide Insert Holders.

Carbide Inserts. Economy Carbide Inserts. Economy Indexable Turning Tools. Economy Indexable Turning Tool Sets. Cubic Boron Nitride Inserts. Alumina Ceramic Inserts. Indexable Cutoff and Grooving Tools. Cutoff and Grooving Carbide Inserts. Mount blade-style holders to a lathe tool post.

Indexable Grooving and Profiling Carbide Inserts. Indexable Cutoff and Grooving Carbide Inserts. Indexable Threading Tools. High-Performance Grooving Carbide Inserts. High-Performance Threading Carbide Inserts. Economy Indexable Threading Tools.

Indexable Boring Tools. Boring Carbide Insert Holders. These holders conform Lathe Tools Uses Case to ANSI standards. Indexable Internal Profiling Tools.

Internal Profiling Carbide Insert Holders. Lathe Chucks. Lathe Chuck Wrenches. Self-Ejecting Lathe Chuck Wrenches. Three-Jaw Lathe Chucks. Machinable Lathe Chuck Jaws. Hardened Lathe Chuck Jaws.

Chuck Stops. Lathe Chuck Jaw Nuts. Lathe Chuck to 5C Collet Adapters. Knurling Lathe Tools. Manual Lathe Knurling Tools. Attach these tools to a manual lathe. Long-Life Knurls. Create a knurled pattern on the end of a workpiece.

Work faster by using two knurls at the same time. Lathe Centers. Live Centers for Intermittent Use. Live Centers for Continuous Use. Pipe and Tubing Live Centers. Dead Centers. Lathe Drivers. Lathe Mandrels. Expanding-End Lathe Mandrels. Expanding-End Lathe Mandrel Sets. Wide-Diameter Range Lathe Mandrels. Solid Lathe Mandrels. Lathe Guards. Adjustable Lathe Guards. Grip square-shank lathe tools. Quick-Change Lathe Tool Posts.

Boring Tool Holders for Milling Machines. Belt Sanders for Lathes. Linear Scales with Digital Readout for Lathes.

By using this website, you agree to our Terms and Conditions and Privacy Policy. The quick brown fox jumped over the lazy dog. Pedestal 35" Ht. Along- the- Length Turning. External Grooving. External Profiling. External Threading. Grind- Your- Own. Internal Threading.

Internal Grooving. Face Grooving. Internal Profiling. Face Knurling. Cast Iron. Hardened Steel. Heat- Resistant Alloys. Stainless Steel. Tool Steel. Right Hand. Left Hand. High- Speed Steel. Carbide- Tipped Hardened Steel. Cubic Boron Nitride. SiAlON Ceramic. Morse Taper. R8 Taper. AL- 4. AL- 5. AL- 6. AL- 7. AL- 8. AL- AR- 4. AR- 5. AR- 6. AR- 7. AR- 8. AR- BL- 4.

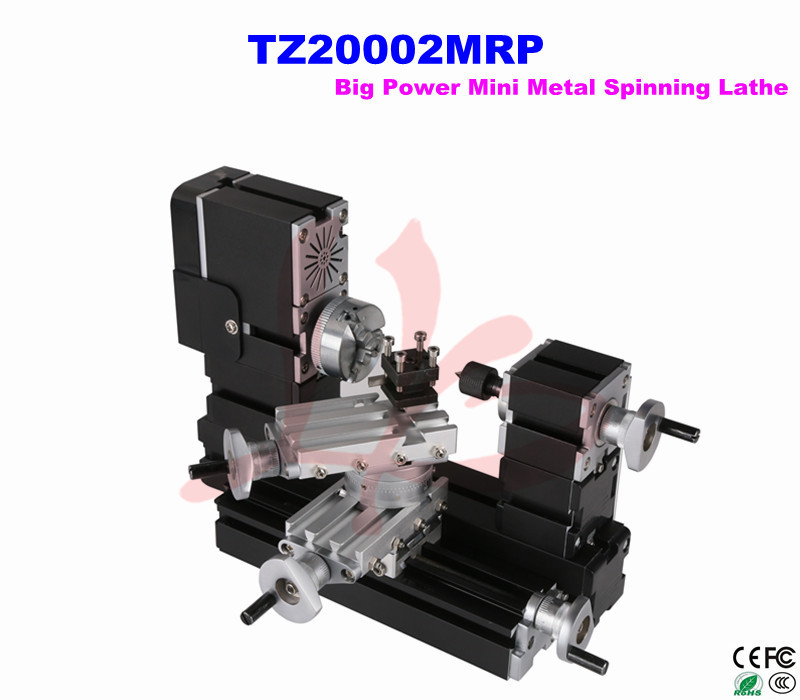

BL- 5. BL- 6. BL- 7. BL- 8. BL- BR- 4. BR- 5. BR- 6. BR- 7. BR- 8. BR- C- CT- CTL- D- E- EL- 5. EL- 6. EL- 8. EL- ER- 5. ER- 6. ER- 8. ER- By the way, you can find out my pick for the top-listed metal lathe out there if you want after reading this. The lathe has two ends, the headstock, which spins, and the tailstock, which stays still to support the workpiece. There are two typical measurements in lathes to look into.

One is the distance between the centers of the headstock and the tailstock moving it into the end. The other measurement is called the center height. It generally gives the idea of the swing measurement while purchasing a lathe. Swing measurement denotes the distance between the center of the headstock and the bed. Some of the small lathes have only three speeds or pulse width modulated DC motors. On the contrary, some might have gearboxes that can be even up to 6-speed gearboxes starting from to rpm to rotate the spindles.

Metal Lathes are used for numerous projects. Each of them is different in operation like cutting, drilling, boring, etc. Here are steps you need to follow to use a metal lathe as a beginner for sharpening a drill bit. In the bit sharpening operation, you will have to use a bit and a piece of aluminum. Before starting, you need to understand some terms of the bit.

Those are called back rake, which is the angle on the top of the bit. There are positive, negative, and zero back rakes if you see them from the side. Negative bits are generally used for high force cutting. We are going to use positive rakes in this operation.

There is also Lathe Turning Tools Metal Zero side rake; that angle affects chip dispersal and heat also. Nose radius is another thing I would suggest a bit that would help your bit from cracking or Lathe Tools Used For Sale 3d chipping out faster.

When it comes to grinding your bit, you have to think about the clearance angle. Think about a piece coming at your left side. If you place the bit horizontally to the object, it would be turning, and if vertically, it would be facing. The next thing you are going to do is making your bit centered up. Whatever it is, a three-jaw chuck or four-jaw chuck, just bring the chucks altogether using your chuck key. Now put the bit in the bit holder and tighten it properly.

Bring the tool holder with the bit mounted on it closer to the center of the chuck as much as possible. Turn on the spin. Next, manually bring the tool holder closer to the workpiece and put it horizontally with the aluminum for the turning. You can see the angle allowing the curls coming out of the piece to drop back and off the bit. Move the bit in a vertical line with the aluminum, and it will do the facing.

So, you can do both the turning and facing on the same bit. This type of face cut is typically good for soft materials like steel or aluminum etc.

A good way to ensure if the bit is still centered up is to find any edges on the facing surface.

|

48 Inch Radial Arm Saw 90 3d Cnc Wood Carving Services 01 Kitchen Cabinet Drawer Rails In |

PRIZRAK

12.09.2020 at 12:32:17

ISMAIL

12.09.2020 at 11:21:50

Roska

12.09.2020 at 20:53:53

ZAYKA

12.09.2020 at 20:30:24

Avto_Pilot

12.09.2020 at 23:41:39