Lathe Turning Tools Explained 65,Wood And Work Lyrics,Ball Bearing Drawer Slides Repair Card,Table Top Cnc Lathe Machine 400 - For Begninners

These tools are preferred in production work as a very long cutting surface can be used resulting in longer tool life. The centre of the tool is set slightly above the centre line of the work to provide an effective front clearance angle on the tool. The tool will rub against the work if the centres are of the same height.

Regrinding is done by grinding the flat only. A boring tool is similar to a left-hand external turning tool so far its cutting edge is concerned.

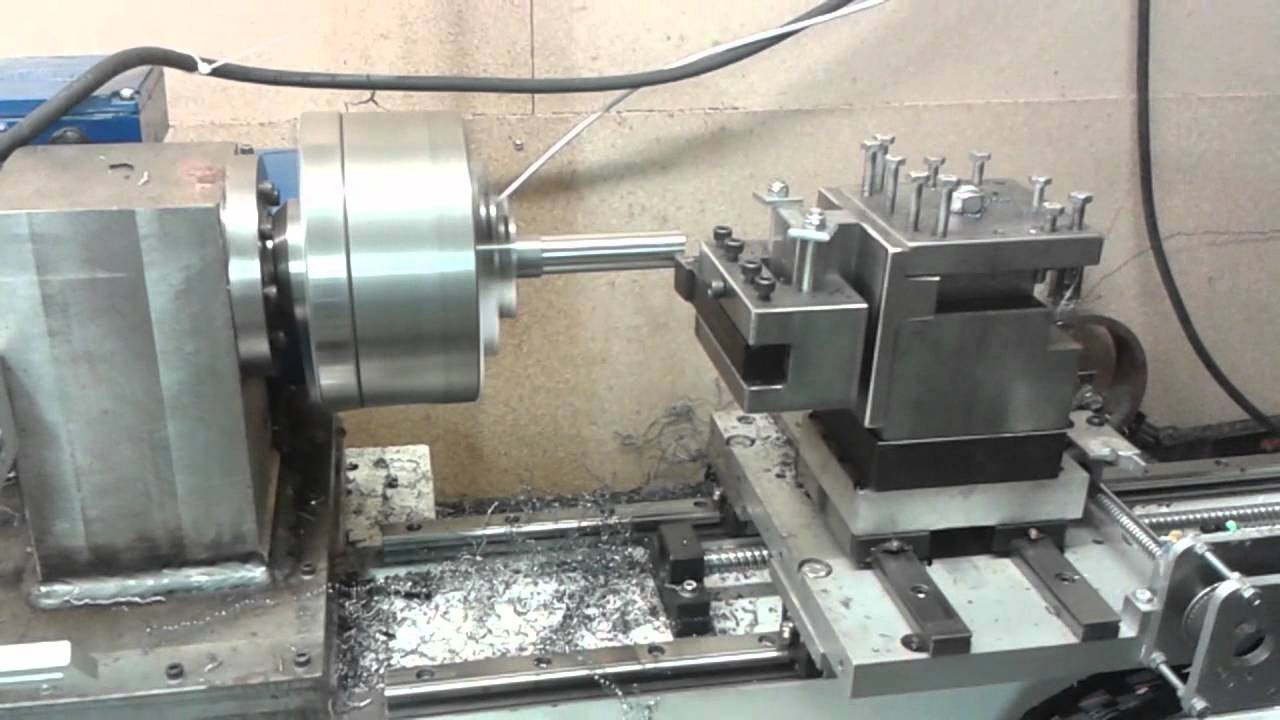

The tool may be a bit type inserted in a boring bar or holder, or forged type having a tool shank. The figure shows an H. A boring bar is made of mild steel with slots or holes cut into it to accommodate the tool bit which is locked by an Allen screw. The amount of projection of the cutting edge of the tool from the centre of the bar determines the finished hole diameter of the work.

The bit is generally inserted at right angles to the centre line of the bar for boring a continuous hole passing from one end to the other end. The bit is set at a single to the axis projecting beyond the end of the bar for boring a blind hole. The counterboring operation can be performed by an ordinary boring tool. The tool cutting edge is so ground that it can leave a shoulder after turning.

A counterbore having multiple cutting edges is commonly used. Undercutting or grooving tool has a point and form of the cutting edge exactly similar to the form of the required groove. Clearance angle is given at all the sides of the tool.

For the recessing groove cutting edge, the longitudinal feed is employed. The front clearance angle depends Lathe Turning Tools Explained Degradation upon the bore of the work. A parting off tool is normally forged and used as bits for cemented carbide tipped tools. Parting off tool is made as narrow as possible to remove the minimum of metal. The width of the cutting edge range from 3 to 12 mm only. The length of the cutting tool which inserts into the work should be slightly longer than the radius of the bar stock being machined.

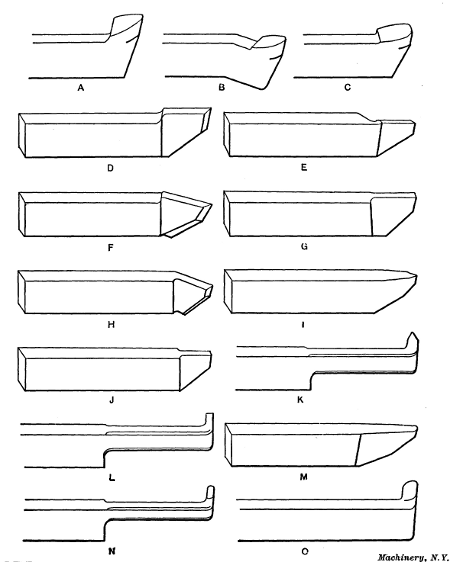

As the tool penetrates deep into the work, clearance is provided all around the tool cutting edge to prevent it from rubbing against the work surface. As the tool is purely ended cutting it has no side rake slight back rake is provided on the tool to promote an easy flow of the ships. A right-hand tool is shown in the figure.

Is that which is fed from lathe bed, i. A right-hand tool is formed on its left-hand end when viewed from the top with its nose pointing away from the operator. The left-hand tool is shown in the figure. Is that which is fed from the Left to the right-hand end of the lathe bed, i. The left-hand tool is used for left-hand thread cutting operation or turning operation which leaves a shoulder on the right-hand end of the workpiece.

A left-hand tool has its cutting edge formed on its right-hand end when viewed from the Turning Tools For Mini Lathe 95 top with its nose pointing away from the operator. A round nose turning tool sown in the figure. Maybe fed from left to the right or from right to the left-hand end of the lathe bed away. For this reason, they have no back rake and side rake. In some cases, a small back rake is provided on the tool.

A round nose turning tool is usually used for finish turning operation. If you found this article helpful please share with your friends. Download PDF. Email Address. Sign in. Log into your account. Forgot your password? Privacy Policy. Password recovery. Recover your password.

The Engineers Post. By Saif M. On: October 31, Types of Lathe Cutting Tools Contents show. Types of Lathe Cutting Tools. Lathe Cutting Tools:. Watch Slideshow Of This Post:. According to the method of using the tool 4.

Turning Tool. Chamfering Tool. Shoulder Turning Tool. Thread Cutting Tool. Facing Tool. Grooving Tool. The dominant material used to make the tools is wood. This simple woodturning tools is made up of 3 Carbide Lathe Turning Tools. Each tool is This pack is suitable for different skill levels, beginners included. No sharpening is needed before the initial; use. The tools should be kept on the floor, i. The best wood lathe tools are made from high-speed aluminum materials. These tools have multiple sharp edges that give you the advantage to turn them several times without sharpening.

This simple woodturning tool is made up of stainless steel tools. The tools available in this set include detailer, rougher, and shear cutter. Each of the listed tools come in a package of three other more tools,. The shear cutter package consists of a round shaft, saucer-shaped carbide cutter, screw, and Torx wrench to produce an excellent finish on the wood you are working on.

This set provides you with excellent roughing and profiling. The detailer is made of a square shaft, diamond carbide cutter, screw, and Torx wrench. This set offers a subtle and detailed finish to your woodwork activities. Some of the tools are multi-sided to allow for rotation of the blades. The chisel heads are already sharpened hence no need to sharpen before use. The tools are made of a 6. These best wood lathe tools are contained in a wooden case with double layer panels, thickened hinges, and enlarged in size to keep the tools safe and in perfect condition.

The tools are not battery-powered, and the entire wooden package case weighs 7. All the tools are made from high-speed steel. The set is made up of three pieces of wood finishing tools such as finisher, rougher and detailer, Carbide Insert Cutters and Allen Key. The tools have a length of These tools are made from high carbon steel, wood, and tungsten carbide.

They are designed to be kept off the floor. The set is already sharpened hence no need for sharpening during first-time use. The set is perfect for any level of skills ranging from beginners to pro levels. The tools are not battery powered and measure a total weight of 3. This carbide wood lathe tool consists of hollower, rougher, and detailer. The set can be used for any skill levels and are designed to make your work enjoyable and straightforward.

The tools are already sharpened have a rotatable carbide cutter, which enables you to rotate the blades without the need to sharpen. The best wood lathe tools are made from aluminum to guarantee lightweight, durability, and balance. The tools are more durable, stiffer, and less likely to round compared to other tools. The package weighs 4. The tools are not battery powered. When you decide to invest some money in a lathe and opt to turn your own, then you are surely going to need woodturning tools along with your lathe.

As a beginner, you may not be sure of the basic and Best wood lathe tools you will need. Also, Lathe Turning Tools Explained 12 buying any and every tool can seem like a huge investment as a beginner.

When you turn a recent catalog, it can be mind-baffling with so many turning tools on offer. So, here you will understand some basic woodturning tools that you require for beginner use. Roughing out is shape your work with edges being rounded off and offering the blank more stability. It is a heavy woodturning tool that is ideally suited for quick elimination of waste wood. This is similar to carving and bench gouges. TIP: It is suggested to cut from high to low sections.

Approach the blank in its flattest position possible. Spindle gouge comprises of lighter blades as compared to roughing gouges.

They possess standard flutes. This is a useful tool for placing intricate details such as coves and beads. It is considered the toughest tool for woodturning. Learning to use appropriately is essential to get good results.

It is very versatile. Parting tools have dual bezels, too; however, they have ground on the narrow edges of the blade. The alignment of the cutting edge is to the thicker rib, which runs down the center of the blade. The parting tool does not give a smooth finish as it is not meant for that. It is primarily used for bowl shaping.

For a beginner, the Best wood lathe tools are around 5 to 8 tools used for a specific purpose with their own characteristics. Understanding your woodturner tools is an essential part of a beginner, as this will help you get the best out of all the tools. A basic kit is sufficient to start with woodturning. Once you are comfortable using them, gradually, you can expand your tool kit depending on your needs.

Table of Contents. You Might Also Like.

|

Best Rap Love Songs 2020 Wallet Drawer Slide Metal Rear Mounting Bracket Brackets Drawer Slides 36 Inch Soft Close Drawer Slides Amazon Editor |

NELLY

22.01.2021 at 16:39:48

BOY_FIESTA

22.01.2021 at 14:43:45

KLan_A_PLan_Ka

22.01.2021 at 10:57:16