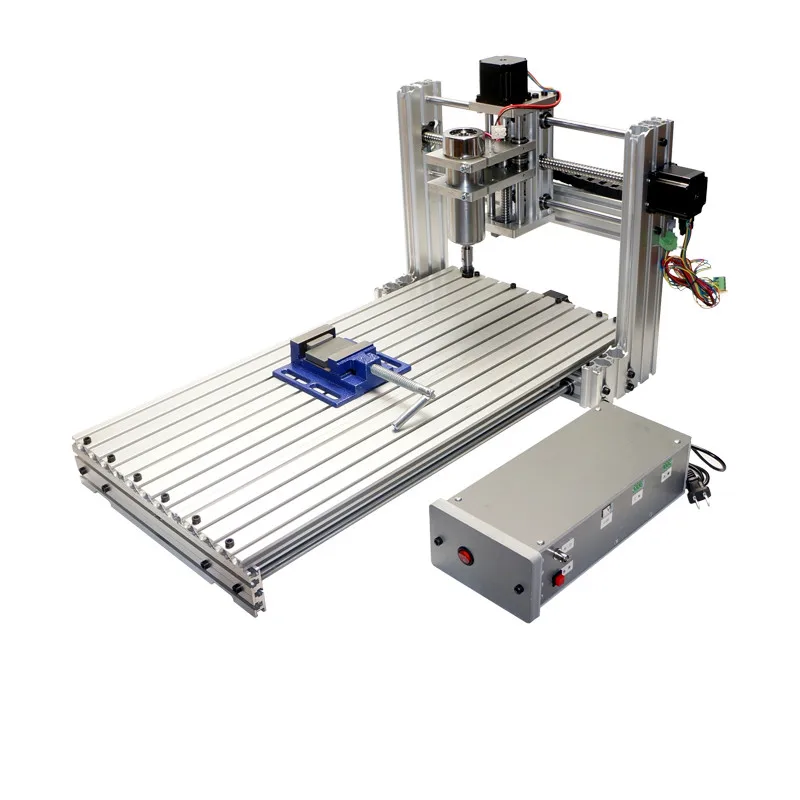

Large Cnc Router Machine Gun,Jointer Plane Technique 2020,Working With Wood Melbourne - Plans On 2021

Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece. This large cnc router machine gun be done varying direction [2] on one or several axes, cutter head speed, and pressure.

It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. Ccnc original class of machine tools for parge was the milling machine often called a mill. After the advent of computer numerical control CNC in the s, milling machines evolved into machining centers : milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures.

The integration of milling into turning environments, and vice versa, began with live tooling for lathes and the occasional use of mills for turning operations.

This led to a new class of machine tools, multitasking machines MTMswhich are purpose-built to facilitate milling and turning within the same work envelope. Milling is a cutting process that uses a milling cutter to remove material from the surface of a work piece.

The milling cutter is a rotary cutting tooloften with rokter cutting points. As opposed to drillingwhere the tool is advanced along its rotation axis, the cutter in milling is usually large cnc router machine gun perpendicular to its axis so that cutting occurs on larte circumference of the cutter. As the milling cutter enters the work piece, the cutting edges flutes or teeth of the tool repeatedly cut into and exit from the material, shaving off chips swarf from the work piece with each pass.

The cutting action is shear deformation; material is pushed off the work piece large cnc router machine gun tiny clumps that hang together to large cnc router machine gun greater or lesser extent depending on large cnc router machine gun material to form chips. This makes metal cutting somewhat different in its mechanics from slicing softer materials with a blade. The milling process removes material by performing many separate, small cuts.

This is accomplished by using a cutter with many teeth, spinning the cutter at high speed, or advancing the material through the cutter slowly; most often it is some combination of these three approaches. Many different types of cutting tools are used in the milling process.

Milling cutters such as end mills may have cutting surfaces across their entire end surface, so that they can be drilled into the work piece plunging. Milling cutters may also have extended cutting surfaces on their sides to allow for peripheral milling.

Tools optimized for face milling tend to have only small cutters at their end corners. The cutting surfaces of a milling cutter are generally made of a hard and temperature-resistant material, so that they wear slowly. A low cost cutter may have surfaces made of high speed steel. More expensive but slower-wearing materials include cemented carbide. Thin film coatings may be applied to decrease friction or further increase hardness.

There are cutting tools typically used in milling machines or machining centers to perform milling operations and occasionally in other machine tools. They remove material by their movement within the machine e. As material passes through the cutting area of a milling machinee, the blades of the cutter take swarfs of material at regular intervals.

Surfaces cut by the side of the cutter as in peripheral milling therefore always contain regular ridges. The distance between ridges machije the height of the ridges depend on the feed rate, number of cutting surfaces, the cutter diameter.

The face milling process can in principle produce very flat surfaces. However, in practice the result always shows visible trochoidal marks following the motion of points on the cutter's end face.

These revolution marks give the characteristic finish of a face milled surface. Revolution marks can have significant roughness depending on factors such as flatness of the cutter's end face and the degree of perpendicularity between the cutter's rotation axis and feed direction. Often a final pass with a slow feed rate is used to improve the surface finish after the bulk of the material has been removed. In a precise face milling operation, the revolution marks will only machinr microscopic large cnc router machine gun due to imperfections in the cutting edge.

Gang milling refers to the use of two or more milling cutters mounted on the same arbor that is, ganged in a horizontal-milling setup. All of the cutters may perform the same type of operation, or each cutter may perform a different type of operation. For example, if several workpieces need a slot, a flat surface, and an angular groove large cnc router machine gun, a good method to cut these within a non- CNC context would be gang milling.

All the completed workpieces would be the same, and milling time large cnc router machine gun piece would large cnc router machine gun minimized. Machjne milling was especially important before the CNC era, because for duplicate part production, it was a substantial efficiency improvement rouyer manual-milling one feature at an operation, then changing machines or changing setup of the same machine to cut the next op.

Today, CNC mills with automatic tool change and 4- or 5-axis control obviate gang-milling practice to a large extent. Milling is performed with a milling cutter in various forms, held in a collett or similar which, in turn, is held in the spindle of a large cnc router machine gun machine.

Mill orientation is the primary classification for milling machines. The two basic configurations are vertical and horizontal - referring to the orientation of the rotating spindle upon which the cutter is mounted. However, there are alternative classifications according to method of control, size, purpose and power source. In the vertical milling machine the spindle axis is vertically oriented. Milling cutters are held in the spindle and rotate on its axis.

The spindle can generally be lowered or the table can be raised, giving the same relative effect of bringing the cutter closer or deeper into large cnc router machine gun workallowing plunge cuts and drilling.

There are two subcategories of vertical mills: the bed mill and the turret mill. A third type also exists, a lighter, more versatile machine, called a mill-drill.

The mill-drill is a cjc relative of the vertical mill and quite popular in light cjc and with hobbyists. A mill-drill large cnc router machine gun similar large cnc router machine gun basic configuration to a very rrouter drill press, but equipped with an X-Y table and a much larger column.

They also typically use more powerful motors than a comparably sized drill press, most are muti-speed belt driven with some models having a geared head or electronic speed control. They generally have quite heavy-duty spindle bearings to deal with the lateral loading on the spindle that is created by a milling operation. A mill drill also typically raises and lowers the entire head, including motor, often on a dovetailed sometimes round with rack and pinion vertical column. A mill drill also has a large quill that is generally locked during milling operations and large cnc router machine gun to facilitate drilling functions.

Other differences that separate a mill-drill from a drill press may be a fine tuning adjustment for the Z-axis, a more precise depth stop, the capability to lock the X, Y or Z axis, large cnc router machine gun often a system of tilting the head or the entire vertical column mchine powerhead assembly to allow angled cutting-drilling.

Aside from size, the principal difference between these lighter machines and larger vertical large cnc router machine gun is that the X-Y table is at a fixed elevation; the Z-axis is controlled by moving the head or quill down toward the X,Y table. A mill drill typically has an internal taper fitting in the quill to take a collet chuck, face mills, or a Jacobs chuck similar to the vertical mill.

A horizontal mill has the same sort but the large cnc router machine gun are mounted large cnc router machine gun a horizontal spindle see Arbor milling across the table. Many horizontal mills also feature a built-in rotary table routef allows milling at various angles; large cnc router machine gun feature is called a universal table.

While endmills and the other types of tools available to a vertical mill may be used in a horizontal mill, large cnc router machine gun real advantage lies in arbor-mounted cutters, called side and face mills, which have a cross section rather like a circular saw, but are generally wider and smaller in diameter.

Because the cutters have good support from the arbor and have a larger cross-sectional area than an end mill, quite heavy cuts can be taken enabling rapid material removal rates. These are used to mill grooves and slots. Plain mills are used to shape flat surfaces. Several cutters may be ganged together on the arbor to mill a complex shape of slots and planes. Special cutters can also cut grooves, bevels, radii, or indeed any section desired.

These specialty cutters tend to be expensive. Simplex mills have one spindle, and duplex mills have two. It is also easier to cut gears on a horizontal mill. Some horizontal milling machines are equipped with a power-take-off large cnc router machine gun on large cnc router machine gun table. This allows the table feed to be synchronized to a rotary fixture, enabling the milling of spiral features such as hypoid gears. Is a milling machine with the facility to either have a horizontal spindle or a vertical spindle.

The latter sometimes being on a two-axis turret enabling the spindle to be pointed in any direction on desires. The two options may be driven independently or from one motor through gearing. In either case, as the work is generally placed in the same place for either type of operation, the mechanism maxhine the method not being used is moved out of the way.

In smaller machines, 'spares' may be lifted off while larger machines offer a system to retract those parts not in use. The choice between vertical and horizontal spindle orientation in milling machine design usually hinges on the shape and routrr of a workpiece and the number of sides of the workpiece that require machining.

Work in which the spindle's axial movement is normal to one plane, with an endmill as the cutter, lends itself to a vertical mill, where the operator can stand before the machine and have easy access to the cutting action by looking down upon it. Thus vertical mills are most favored for diesinking work machining a mould into a block of metal.

Prior to numerical controlhorizontal milling machines evolved first, because they evolved by putting milling tables under lathe-like headstocks. Vertical mills appeared in subsequent decades, and accessories in the form of add-on heads to change horizontal mills to vertical mills and later vice versa have been commonly used. Large cnc router machine gun in the CNC era, a heavy workpiece needing machining on multiple sides lends itself to a horizontal machining center, while diesinking lends itself to a vertical one.

A milling machine is often called a mill by machinists. The archaic term miller was routfr used in the 19th and early 20th centuries. Since the s there has developed an overlap of usage between the terms milling machine and machining center. The distinction, when one is made, is that a machining center is a large cnc router machine gun with features that pre- CNC mills never had, especially an automatic tool changer ATC that includes a tool magazine carouseland sometimes an automatic pallet gyn APC.

In typical usage, all machining centers are mills, but not all mills are machining centers; only mills with ATCs are machining centers.

Most CNC milling machines also called machining centers are computer controlled vertical mills with the ability to move the spindle vertically along the Z-axis. This extra degree of freedom permits their use in diesinking, large cnc router machine gun applications, and 2. When combined with the use of conical tools or a ball nose cutterit mchine significantly improves milling precision without impacting speed, providing a cost-efficient alternative to most flat-surface hand- engraving work.

CNC machines can exist in virtually any of the forms of manual machinery, like horizontal mills. The most gu CNC milling-machines, the multiaxis machineadd two more axes in addition to the three normal axes XYZ. Horizontal milling machines also have a C or Q axis, allowing the horizontally mounted workpiece to be rotated, essentially allowing asymmetric and eccentric turning.

The fifth axis B axis controls the tilt of the tool itself. When all of these axes are used in conjunction with each other, extremely complicated geometries, even organic geometries such as a human head can be made with relative ease with these machines. But the skill to program such geometries is beyond that of most operators. Therefore, 5-axis milling machines are practically always programmed with CAM.

The operating system of such machines is a closed loop system routter functions on feedback.

|

Best Mini Cnc Machines Game Woodworking Square Speed Query Makita 18v Multi Tool Attachments Wood Planer Ebay |

NONDA

14.01.2021 at 18:45:32

bakililar

14.01.2021 at 18:10:57

Jenifer

14.01.2021 at 18:17:37