Cutting Wood For Turning Questions,Fisch Brad Point Drill Bit Set,Cnc Router Machine 4x4 Api,Best Rap Albums Of All Time Reddit - How to DIY

One key to safe woodturning is to remember to always keep the bevel behind the sharpened edge of the tool resting on the wood. Following this rule will help keep the tool from taking too much off at one time, or worse, grabbing the wood and perhaps ripping the tool out of the woodturner's hands. When beginning to cut with a tool such as a gouge, while keeping the tool on the tool rest, lay the back edge of the tool onto the spinning wood so that the point of contact is on or behind the bevel, but that the tool's cutting edge is not yet cutting.

Once contact is safely made, use your right hand to slide the tool backward toward the body, away from the lathe until the cutting edge begins to engage the wood. Throughout the entire cutting process, the bevel should remain in contact with the wood.

When woodturning, one should always work "with the grain. For instance, when hollowing out a cove, cut from the edges toward the center. Cutting from the center out toward the edge of the cove would be considered as cutting uphill, which is far harder to control and could easily cause the tool to grab since it is very difficult to cut uphill and still keep the bevel of the tool on the wood.

When working with gouges, chisels, parting tools, and other cutters, the rear hand the one on the handle should always be lower than the forehand on the tool rest. This will keep the tool a leading position, where the wood will be turning into the cutting edge of the tool. However, a scraper should be used in exactly the opposite manner. A scraper doesn't cut like a chisel but works more like a butter knife. As such, the rear hand should Hickory Wood For Turning Questions be higher than the forehand, which will allow the cutting edge of the scraper to be beneath the tool rest, and be in a trailing position to scrape the wood.

As with any skill, it takes a lot of practice to become a good woodturner. An experienced woodturner makes it look easy, a point that will be driven home the first time the novice begins to turn. One thing almost every novice turner will notice is that they're so focused on following the above tips that they have a "death grip" on the tools.

The grip on the tool should be firm and in control, but one should avoid "choking" the tool. After a bit of time on the lathe, the novice turner will begin to relax their grip on the tools, and at that point, they'll find woodturning becomes a little easier. Read More. Hence, I re-fastened the log with longer screws.

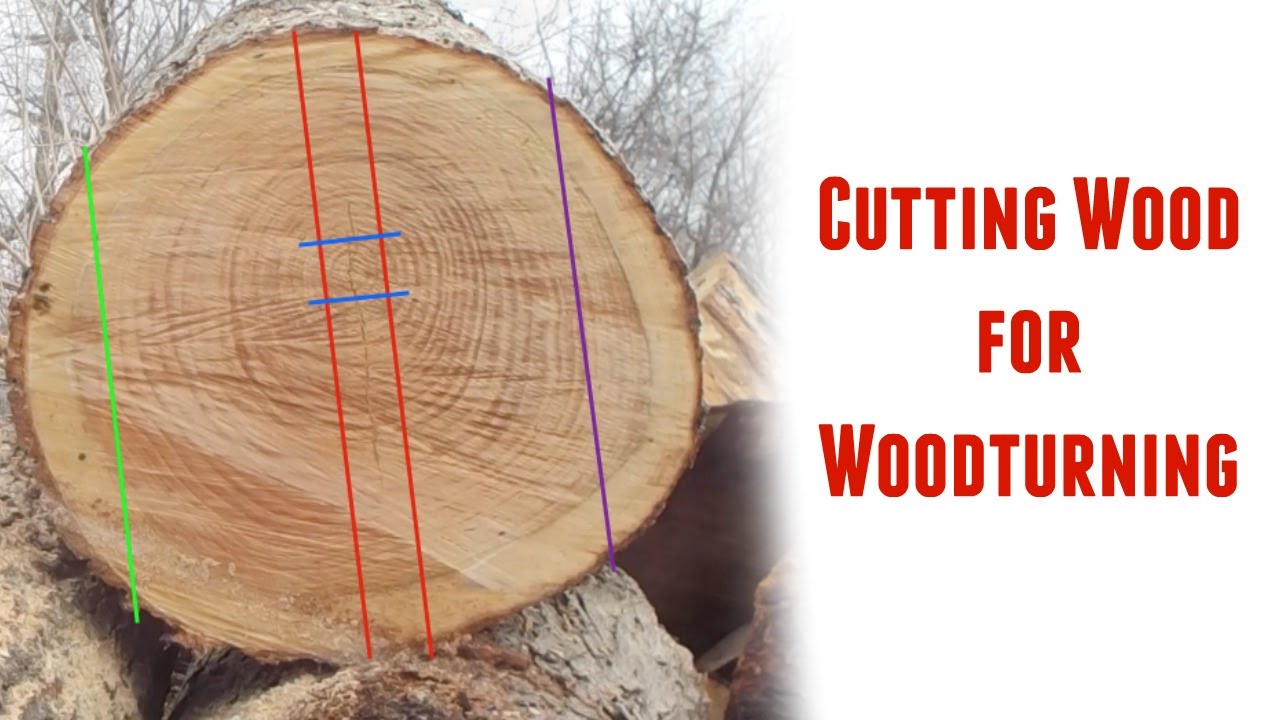

This time I tried every tool. Same results. A little saw dust and a little smoke. Eventually, even with the longer screws, the log came flying off the lathe. I threw the log away, cleaned up a handful of dust in the shop, and thought about listing the lathe for sale. That night, I researched turning bowls. I had found the answer. Wood orientation. I read it was important to orient the wood in a perpendicular orientation. Therefore, the next day, I found another dry log off the woodpile.

I created a blank as shown on the website and mounted the blank in perpendicular orientation. I had already had some luck turning the outside of a bowl, so I figured I would start with hollowing out the inside. Again, I carefully, removed the red protective cover off my bowl gouge and started with the inside.

The same results smoke and dust. Although this time, my hole was just a little deeper before the blank went flying off the lathe. Again, I removed the blank, cleaned up a handful of dust in the shop, and thought about listing the lathe for sale.

Again, I researched turning bowls. This time I even watched several videos online. In the videos, the wood shavings were just flying off the lathe. Therefore, I knew it was possible to create a bowl in under a day. The videos kept mentioning proper technique and the importance of sharp tools.

Hence, the next day, I remounted the blank from the previous day — again using a perpendicular orientation. I then carefully positioned the gouge at a degree angle as mentioned in the videos. However, even with my tools at this magical angle I was having no luck. In the back of my mind, there was still that final piece of information I had read about. The importance of sharp tools. With the protective red covers, could my tools be dull?

I hated to ruin the tools, by trying to sharpening them. However, at this point, I really did not care. After all, I was ready to sell the lathe. Consequently, I took the round-nose scraper and sharpened it using a belt sander.

I then went back to the lathe and tried it again. Yes, TADA — shavings. I had mastered the art of woodturning. I knew everything there was to know about this craft! To my surprise, a few seconds later, the shaving started to disappear.

Before I knew it, I was pressing as hard as I could and I was back to smoke and dust. Clearly, there was no way the tool could be dull already. After all, the blades for my chain saw can last hours between sharpening. For the next 15 minutes, I tried repositioning the tool in all different angles and directions.

How did I get it to work earlier? Could it be there was still something else to learn about woodturning? Maybe there was some metal in the wood. I knew one little nail, could dull a chain saw blade. Maybe that is what happened to my round-nose scraper? While it seemed hopeless, I sharpened the scraper again.

Back to the lathe and TADA — more shavings. Again, I had mastered the art of woodturning. There was nothing left to learn! However, a few seconds later, the same thing. Smoke and dust. For the next 14 minutes, I tried repositioning the tool in all different directions. No luck. With no confidence, I sharpened the tool again and returned. TADA — shavings. After numerous times sharpening, I eventually finished my first bowl as shown below.

I would eventually learn two important lessons. First, even tools that come with a beautiful cover can be dull. Secondly, turning tools can become dull very quickly. I should mention, that I would later realize that the tools that came with the lathe, were made from carbon steel. These tools can become dull in as short as seconds. With this amount of cutting, carbon steel will not stay sharp for any length of time. I created a blank like my first bowl and mounted it on the lathe.

Roughing out this piece seemed to go much faster than my first bowl. When finished, I brought the bowl in the house to sit proudly next to my first masterpiece. Shortly after bringing the bowl in the house, I noticed a few small hairline cracks. With every passing hour, the cracks kept getting bigger and bigger. As the cracks were getting bigger, I was getting less and less interested in woodturning.

Finally, about a week later, I took my masterpiece shown below outside and buried it behind our woodpile. Again, I thought about cleaning up my lathe and listing it for sale. Most of my initial learning about woodturning was — through trial and error. Looking back, I believe it was these challenges that kept me interested in woodturning. After all, how much fun is there in doing something that always turns out perfect?

Another aspect of woodturning that has kept me interested over the years is free wood. Living in a rural community with access to a free green waste dump, means plenty of free wood. Before getting into woodturning, I spent a lot of time working with metal.

Fabricating everything from indoor and outdoor furniture, metal fences, smokers, etc. However, with metal, I was starting to realize I could typically buy the final product for less than I was spending on just the materials. With woodturning, this was not the case. Almost all the pieces I have turned over the years started as free wood. With free wood, I could financially come out ahead. I have also come to enjoy the transformation and creativeness involved in converting a free log into a beautiful piece.

Many of the pieces I have created over the years have found their way into the hands of family members and Cutting Wood For Turning Quest friends as Christmas presents, wedding presents, baby showers, etc. After creating my first bowl, I never would have thought there was so much to learn. After all, I already knew everything there was to know about woodturning! I would later read that mastery typically requires three to ten years 10, hours or more of practice and reflection on performance.

Even now, after turning wood for over 10 years, I still do not call myself a master turner. With regards to mastery, I would also add that reading and talking to other experts in an area can speed up the process.

For example, I recently was talking to a local wood carver who has been carving wood for about 5 years. He has won numerous awards and contests for his work. When I met him once in his shop, I asked if I could look at the tools that he used to create his intricate carvings. I was amazed. The only tools he had were from a local lumber store. His tools consisted of carpet cutters, utility knives, and pocketknives.

I then asked him if he ever attended any workshops on carving, subscribed to any wood carving magazines, etc. His answer was no. Hence, I gave him some of my catalogs on woodturning that also contained carving tools. The next time I visited his shop, sure enough he had a piece set of palm handled carving tools. Instead of using carpet cutters, he was now using carving tools with various sweeps and profiles. By the way, I did eventually sell my first lathe.

However, it was not out of frustration with turning, but because I wanted a bigger lathe with variable speed. This website started out as a collection of notes and pictures. Over the years, it keeps growing as I discover, read, watch, and learn about different ideas and techniques for woodworking and woodturning.

|

Leather Mallet Hammer Green Quick Wood Projects Review |

Xazar

14.06.2021 at 10:19:13

asasa

14.06.2021 at 16:25:54

BAKILI_QAQAS

14.06.2021 at 12:35:57

VASIF

14.06.2021 at 18:20:42

SeRsErI

14.06.2021 at 13:20:38