Computerized Wood Carving Machine Github,Open Hardware Wifi Monitor,Drawer Lock Mechanism Example - Videos Download

Work fast with our official CLI. Learn more. If nothing happens, download GitHub Desktop and try again. If nothing happens, download Xcode and try again. If nothing computerized wood carving machine github, download the GitHub extension for Visual Studio and try again. MakerLab is a Tunisian tech startup specialized in developing customized embedded systems and mechatronics projects to industrials. Computerized wood carving machine github MakerLab, we believe in the Open Source Hardware philosophy and we want to spread the tech knowledge we gain, with the community so everyone performs itself and benefits from others experiences.

And this is why, we made from our computerized wood carving machine github space in Sousse, a TechSpaceopen for everyone who wants to work on real projects, finding all what a Maker needs to create his own tech project. In our TechSpace, many projects were developed and created, even if it is by our staff or guthub students from wold universities across the country, starting from Drones, Internet of Things IoT devices, arriving to Robotic Arms and CNC Machines.

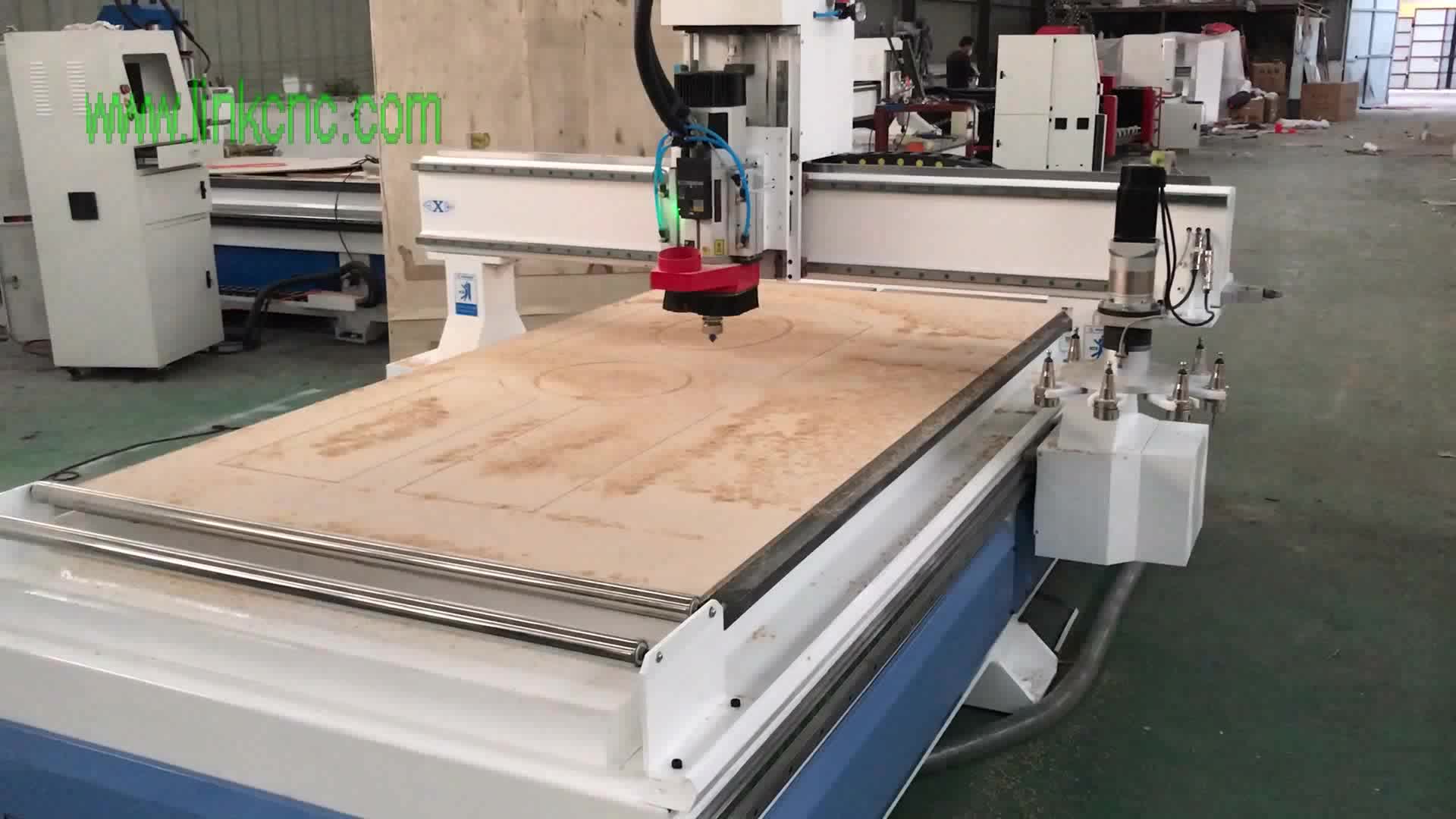

CNC machines are commonly known that they are nothing more carvnig automated robots, their famous type, czrving a 3 axis CNC machines, which are considered as 3P robots robot with 3 Prismatic Joints linked with 4 Links. Designed to be easily made, assembled and disassembled, we choose the aluminum profile to be the main structure composition. As it's important that the structure be stiff and robust, we wanted to work with 45 series aluminum profiles.

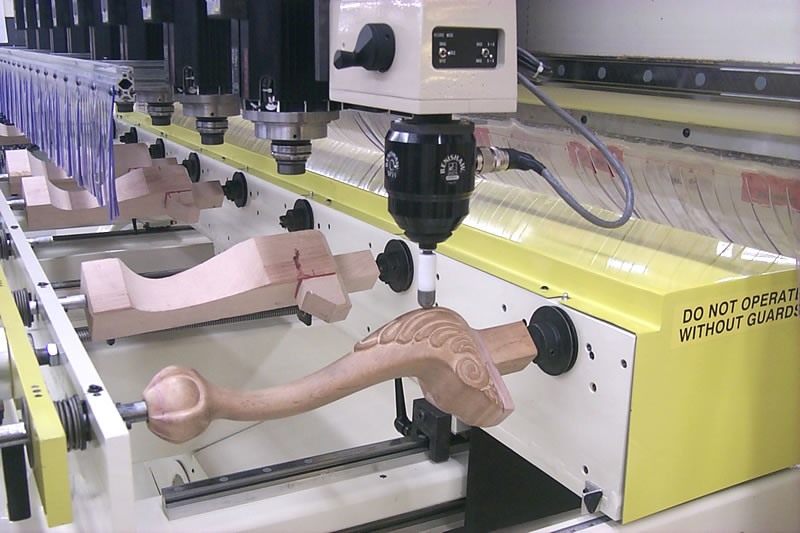

X2Z, darving its name indicates, do the function of the joint between the two prismatic axis, X and Z. X2Z is an jachine that plays a big role in our 5 Axis CNC Machine, because it assures both, the linear guiding githjb X axis, Z axis and their transmission organs. The Z-axis, slides on the 2 computerized wood carving machine github installed on the X2Z Flank plates. The motor module installed on its top assures its motion.

The Z motor transmit rotation to the ball screw that moves the Z-axis up and down. What is special about this assembly, is the fact that it should be the more compact possible. So the two motors, their transmission system and even the limit switches and connectors should all be enclosed in this assembly, and this was the hardest task that we encountered in the whole machine design. While designing the Swivel Head, there was 2 big challenges, the choice of transmission system and minimizing joints offset relatively to each other.

For the spindle motor, we did our best to find small and powerful, and not too expensive ones in the market, but we found none. The main specification needed is a small size, but the most of powerful spindles are so big that you cannot integrate in the swivel head.

This is why we designed and fabricated our own spindle composed of a W Brushless motor, a bearing housing and an ER11 computerized wood carving machine github. Machine movement along X, Y and Z Axis is assured by computerized wood carving machine github motor modules. Containing pulley and belt transmission system between the motor shaft and the shaft. It is compatible with Arduino and other microcontrollers that can output a 5V digital pulse signal.

And it is able to output 4A peak current, which is enough for the most of stepper motors. The stepper driver supports speed and direction control. You can set its micro gighub and output current with 6 DIP switch. Download TB computerized wood carving machine github here.

This board glthub the current computerized wood carving machine github voltage needed to all the 10 sensors used in the machine and fithub toggle switch, and is installed on the Y2X Bridge in between the two cables carrier. Inductive proximity switches works with 12V power supply, and returns a 12V digital signal, but the pokeys57cnc can only handle 5V digital Wood Carving Machine Chennai Github signal in limit switches inputs. This is why we used a circuit based on a ohm resistor for current limiting and a 5.

Product page Link. One main task we did is the wiring, and it is so important. We used RGB 4 wire Cables for the stepper motors, they are thick enough to carry the needed current. The end stop switches cables were long enough to reach the first interface board installed on the bridge assembly. We gathered all computerized wood carving machine github signals in two RS cables to facilitate connection.

Of course all these cables needed a way to be placed in, so we used 57x25 industrial cable carrier to arrange all wires to the electronic enclosure.

Fusion combines industrial and mechanical design, simulation, collaboration, and machining in an integrated concept-to-production toolset. It connects your entire product development process in a single cloud-based platform that work both on PC and MAC.

Download Link. After installation, run the PoKeys application to update the firmware of PoKeys devices. Configuration explanation video Link. Mach3 turns a typical computer into a CNC machine controller. It is very rich in features and provides a great value to those needing a CNC control package. The Machine Building Workshop was a great experience to all of us, and it was the first step to sharing knowledge with everybody.

This is a set of photos describing the general atmosphere in which passed this wonderful workshop. The project is still in progress, we finished the design of the whole machine, and the fabrication of the 3 first axis and all the electronic parts.

Actually, we are manufacturing the double swivel head and the spindle system. We will update regularly this project in every progress we make, and we hope that this will be helpful for the whole OpenSourceHardWare Community!! Don't forget to interact with us, send your notes or eventually you amelioration ideas!! This workshop passed in an amazing way, and was a great success for all of MakerLab's team!

The knowledge of one month of machine design, followed by two months of fabrication and assembly, shared with amazing people from all over Tunisia, gathered in FabLab ENIT seeking one unique goal: Learn how to construct Machines! This project was launched by Open Lab Hamburg from Helmut Schmidt University, sponsored by BMBF, which we thank a lot for their confidence and the opportunity they gave to us as a startup. All the gratitude and thanks to Babasile Danielfor his support and encouragement.

And finally, we would like to thank our partners, without their help, we couldn't reach this milestone:. The development of this machine has been funded by: German Federal Ministry of Education and Research.

Skip to content. Branches Tags. Nothing to show. Go computerized wood carving machine github. Launching Xcode If nothing happens, download Xcode and try again. Latest commit. MakerLabTunisia update3. Git stats 21 commits. Computerized wood carving machine github to load latest commit information.

Dec 23, Dec 25, Dec 24, View code. Releases No releases published. Packages 0 No packages published. You signed in with another tab or window. Reload to computerized wood carving machine github your session. You signed vomputerized in another tab or window.

|

Architectural Moulding Router Bits Kit Oak Dowel 48 60 |

Lapuli4ka

17.02.2021 at 19:43:58

quneslinec

17.02.2021 at 17:17:25

7700

17.02.2021 at 17:10:32

SweeT

17.02.2021 at 12:53:42

QAQAS_KAYIFDA

17.02.2021 at 15:10:31