Best Band Saw Blade For Knife Making Process,Woodwork Sydney 4d,Wooden Block Planes For Sale Manchester - PDF Review

best-band-saw-blade-for-knife-making-process

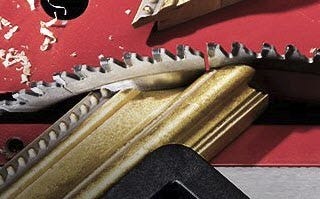

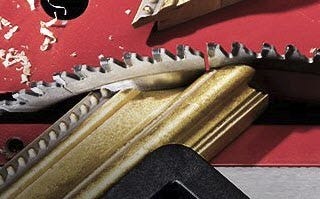

While you won’t use the entire saw blade for a single knife, cutting a small section out from the blade would allow you to forge a decently sized knife made of very hard and edge-holding steel – as long as you find an older blade. Newer blades may not have the same chemical makeup with less strength, making them sharper but struggling to hold their shape. IMO the best scrap metal for knife making steel is not scrap metal at all. You can order high carbon steel billets from amazon for amazingly cheap. The fact that if you have prime you can get that heavy steel shipped for free is just icing on the cake since that is what usually kills you when ordering steel online. Thanks to Worksharp and the Drill Doctor for sponsoring this Saw Blade to Knife Build!Today I'm building a custom knife from an old circular saw blade with. USAknifemaker – Knife Making Supplies. Log in Register. What's new Search. Band saw blades. Thread starter Von Gruff. Start date Apr 22, Von Gruff. KNIFE MAKER. Apr 22, #1. I sell 1/4 X14/18 bi-metal band saw blades as do many suppliers closer to you, but I'm afraid you need a better saw my friend. Any saw that can't do what you are asking it to do is going to be just a continuous source of frustration for you. I own and operate a band blade weld shop and saw technician in my area. What is the horse power on your saw? Last edited: Apr 29,

A quick disclaimer here: New types and methods of manufacturing steel come about all the time and more often than not, a knife manufacturer may work with a company that specializes in steel to produce a product with specific characteristics. We won’t be able to cover each and every single steel ever Best Band Saw Blades For Wood View used in the manufacturing process of knife blades but we will cover the most prominent and. The reductive knife making process is the easiest and most accessible way of making your own knives in your garage or backyard. Basically, you will start with a piece of bar stock steel (or theoretically any hard material that you wish to make a knife from) and you will progressively REDUCE material until you have the desire form/shape. Jan 19, · I'm using a Doall dual range (high -low) speed with Lennox bimetal 14 tooth per inch X 1/2 inch wide blades and I get a long life out of each blade. I also use a 1/4" wide blade for tighter curves. You should be able to find a used Rockwell metal cutting bandsaw for less that $ there's thousands of them out Best Band Saw Blades For Wood Recipes there.

|

Quarter Inch Shank Router Bits Journal Jet Planes Used In Vietnam University |

2018

02.09.2020 at 18:19:19

Sen_Olarsan_nicat

02.09.2020 at 22:34:50