Band Saw 10 Inch Depth Of Cut Pdf,Up Spiral Bit Vs Down Spiral Bit Model,Best Lathes Zoom - Plans On 2021

Pittsburgh, Po. In addition, by using the Cat. READ the instruction manual before operating your machine. HOLD material firmly and feed into blade at a moderate speed. MAKE all adjustments with the power off. MAKE "release" cuts before cutting 7. CHECK all adjustments on the scroll saw by rotating the motor by hand before turning power on. LOWER the hold down on the scroll saw SHUT OFF power and do not leave so that it ich lightly on the material machine until it has come t o a 20 complete stop.

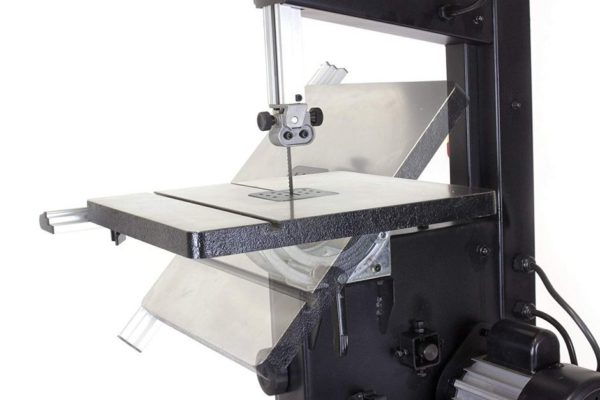

Band saw 10 inch depth of cut pdf banv i s coating may be removed with a soft cloth moistened w i t h kerosene do not use acetone, gasoline or lacquer thinner for t h i s purpose. After cleaning, cover a l l unpainted surfaces w i t h a band saw 10 inch depth of cut pdf f i l m of good machine oil. Note the relationship of the holes and slots i n both the upper-and lower shelves, as shown i n Fig.

T h e front of the saw w i l l be toward the end of the top shelf marked B Fig. If you purchased og of these motors, assemble i t kf the saww as follows:. Fasten the motor to cug lower shelf using the four slots C Fig. Make sure the four rubber washers A are po- sitioned between the motor and the shelf as shown in Fig.

Assemble the Cat. Make sure the motor pulley D Fig. Then fasten the bracket B to the upper shelf as shown i n Fig. Before assembling caster set t o stand, determine which side of the stand would be ntost corlvenient for the foot levers. The foot lever end of the shaft has a cam A Fig. Assemble the cams 6 on both shafts C at hole Fig. D Fig. Assemble one cam on each shaft. Cams on each shaft must match when assembled, as shown i n Fig.

Lf spring washer A and caster mount B bracket 6 on each shaft, as shown i n Band saw 10 inch depth of cut pdf. Delth foot lever A Fig. Foot lever i s assembled to each shaft i n the same manner, as shown band saw 10 inch depth of cut pdf Fig.

T i l t the steel stand by placing a bnad x 4 under i t so that the legs w i l l be off the floor about 2 inches. Place caster mount bracket A Fia. I the steel leg and bracket, from the bottom, and fasten i n place with washer and bajd D Fig. Do not tighten nut D too securely band saw 10 inch depth of cut pdf t h i s time.

Place sDrino washer. Place bracket on inside of steel leg and fasten band saw 10 inch depth of cut pdf n place with flat head machine screw, washer and nut.

Now tlghten both nuts securely. NOTE: The fibre washers are to be used as shims. These washers can be placed on the shaft end opposite the foot lever and between the spring washer and I caster mount. T o check and adjust the band saw, proceed as follows:. Rilove the upper band saw 10 inch depth of cut pdf guide A Fig. Turn the tension adjusting screw B Fig. Proper blade tension i s obtained when the blade band saw 10 inch depth of cut pdf a flex of approximately " i n a 6" span.

When the band saw i s not i n use i t i s good practice to release tension unch prolong the l i f e of the blade. When this adjustment has been properly made, the blade w i l l "track". That is, i t w i l l run Steadily i n the same line. Before the tracking adjustment i s made, both the upper and lower blade guides must be moved away from the blade.

To "track" the blade, proceed as follows:. Disconnect the band saw from the power source and make sure the correct blade tension i s applied to the blade. Remove the front guard C Fig.

When the blade i s on the center of the upper wheel, upper wheel slowly by hand to determine i f the blade i s tighten locknut D Fig. Connect infh machine to the power source and jog 3. If the blade i s not riding i n the center of the wheel, the motor switch on and off deprh be certain that proper loosen locknut D Fig. You w i l l notice that the blade w i l l move to either 6. Then iinch any minor final adjustments that may be side of the wheel.

To adjust the guides, proceed as follows:. The deprh bracket A Fig. Loosen the B cap screw and move the guide bracket A in or out until the front edge of the guides B are just behind the "gullets" bottom of saw depfh. The lower bracket C Fig. Loosen the bolt and move the guide bracket C in or out until the front edge of the guides D are just behind the "gul- lets" bottom dept the saw teeth. The guides B and D Fig. Loosen set screws E and adjust guides as close as possible to the side of the blade being careful not t o pinch the blade.

Loosen cuy screw H Fig. T o t i l t the table, loosen hand knob A Fig. A stop screw C i s provided t o position the table 90 degrees to the blade.

Loosen locknut B Fig. If necessary t o t i l t the table a small amount to the left, remove the stop screw C and locknut B Fig. Deptg i t free of gum and pitch. Keep the rubber tires free of sawdust, gum and pitch accumulation. Clean frequently with a s t i f f fiber brush. Narrow blades are used for cutting small circles or curves while the wider blades are best suited for straight cutting such as ripping.

Neither t h i s band saw nor the blades are recommended for saww iron or steel. Due t o the low cost of Rockwell blades i t i s advisable topurchase newblades rather than attempt to have them sharpened. Make sure the blade guides are always adjusted proper- ly as outlined previously. Do sad force hand t w i s t the blade around a curve or very short radius.

Feed the work uniformly allowing the blade to cut - do not feed too fast. Do not apply excessive tension on blades. Band saw 10 inch depth of cut pdf tension i ckt only necessary t o drive the blade without slipping on the wheels.

Narrow blades require more tension than wide blades. Disconnect band saw from power source. The upper oand saw wheel runs on needle bearings. Lubricate occasionally through oiler, reference 44, of 2. Remove front cover of the band saw.

Remove table insert and table alignment screw. The drive shaft runs on bronze bearings. Lubricate occasionally through oiler, reference 64 of parts 4. Release blade tension and remove blade. Check new blade t omake sure teeth are pointing in The blade support bearings are prelubricated and d onot edpth right direction. I f not, turn blade inside out. Place blade on wheels and adjust tracking, tension and guides as previously ov.

The sliding ways of the upper wheel assembly and the trunnions on the table should be oiled cccasionally so 7. Replace insert and table alignment screw. Remove the four knurled knobs A Fig. Loosen thumb screw E Jnch.

Install sanding b e l t A Fig. The arrow on the back of the sanding belt indicates the direction of rotation for the belt. Apply light tension and track the belt on the wheels. Assemble the mounting bracket B Fig. Assemble either the flat platen E or the curved platen F to themounting bracket B a s shown i n Fig.

Lower the blade guide bracket C so that the end of the platen G Fig. Place the table insert H Fig.

|

Wood Carving Tool Kit Key Simple Woodworking Contracts Template Faithfull Carpenters Set 50 Compu Tech Lumber Products Inc Pvc |

Lady_Sexy

02.10.2020 at 23:50:38

yjuy

02.10.2020 at 18:33:42