Workshop Dust Control Theory,Wood Sanding Machine Bunnings Recipe,Ca Glue For Wood Turning 600,Fine Woodworking Adirondack Chair Plan Temple - Step 2

Dust is the general name for minute solid particles of a diameter of less than micrometers. In construction, demolitionand renovation situations, dust of differing sources poses a serious and recognized health risk to workers causing acute and chronic diseases such as silicosissarcoidosis, asbestosis, coal miner's pneumoconiosis, and other pneumoconiosis type ailments.

In addition to the health risk, dust emissions workshop dust control theory pose a threat with its ability in some sectors to be flammable. Dust in generated from a very wide range of activities both industrially and domestically. Activities such as mining, construction, and agriculture are industries that are large contributors to general atmospheric dust levels. Dust exposure is dependent on the amount of dust emitted, which depends on the physical characteristics of the material and the methods of handling of the material.

Dust exposure generally occurs from, but is not limited to, being exposed to dust from one or more of the following tasks:. Implementing new dust control methods for industrial sites is essential to protecting workers from various dust generating tasks. Dust is produced in a very wide range of sizes.

Larger, heavier particles tend to settle out of the air and onto a surface and smaller, lighter particles have a tendency to hang indefinitely workshop dust control theory the air. There are two main types of dust that exist workshop dust control theory a worksite.

First of all, there is fibrogenic dust. Fibrogenic dust is so named because it is a kind of dust that has fiber like tendencies. Fibrogenic dust is biologically toxic and if retained in the lungs can impair the lungs' ability to function properly. Examples of this kind of dust include asbestos workshop dust control theory and free crystalline silica. Typically, any health effects caused workshop dust control theory inert dust are potentially reversible, as opposed to the fibrogenic dust's more permanent effects.

However, inert dust has the potential to obscure visibility, cause unpleasant deposits in exposed bodily orifices, and potentially injure mucous membranes or the skin with some sort of chemical action.

For occupational health purposes, dust is classified by its size into the three categories of respirable dust, inhalable dust, and total dust. Respirable dust is the kind of dust that is small enough to penetrate deep into the lungs and workshop dust control theory the nose, throat, and upper respiratory tract.

Total dust includes all airborne particles, without regard to size or composition. Dust control is necessary due to both health hazards and industrial problems. Excessive dust emissions can cause such health issues as occupational respiratory diseases; eye, nose, and throat irritation; and skin irritation.

In addition, dust is an industrial problem. With its potential risk of dust explosions and fires, it can potentially damage worksite equipment, it impairs visibility, it can cause unpleasant odors, and it is a potential problem in community relations. As far as health hazards to workers, this occurs when workers are exposed to excessive amounts of harmful dusts.

The harmfulness is dependant on the composition of the dust i. The biggest concern of people exposed to worksite dust is that long-term exposure to certain harmful respirable dusts can cause workshop dust control theory condition known as pneumoconiosis. Pneumoconiosis is a general name for specialized types of dust-related lung disease. Of particular note as far as pneumoconiosis goes, there are three varieties that are much more prominent and common in industrial situations.

First of all is silicosis, which is a chronic, irreversible disease which results in shortness of breath due to scarring of the lung tissue. Crystalline silica is naturally present in the following materials used in construction:.

Secondly, there is the form of pneumoconiosis known commonly as black lung, but whose official name is coal worker's pneumonia CWP. Thirdly, there is the form of pneumoconiosis called asbestosis, which is caused by asbestos fibers. This is an irreversible disease that causes shortness of breath and an increased risk of cancer, including a very rare type of cancer known as mesothelioma.

Typical exposure occurs in mining and demolition sites. Slag is the name for the nonmetallic byproduct that occurs from the production of iron. Slag contains trace amounts of such chemicals as manganese oxide, titanium oxide, chromium compounds, sulfur compounds.

Exposure to slag dust can cause varied reactions including eye irritation, dermatitis, acute inhalation effects, and chronic inhalation effects. Airborne slag dust has the potential to cause immediate or delayed irritation or inflammation of the eyes. Any eye exposure to large amounts of dry powder or wet slag requires immediate first aid in order to prevent workshop dust control theory and permanent damage to the eye.

Slag is capable of causing different skin reactions including dry skin, discomfort, irritation, and dermatitis. The dermatitis reaction can be caused by either irritation or allergies. In the case of irritant dermatitis, this is caused by the innate physical properties of the slag, i. The allergic contact dermatitis however is typically caused by a sensitivity due to the presence of hexavalent chromium in slag.

This reaction can range from mild skin irritation and rash to the presence of severe skin workshop dust control theory. Persons already sensitized may react upon the first contact with slag; however, it is also possible that a person may develop an allergy to the substance after repeat exposure to the slag. In the case of acute inhalation effects, the slag dust has the potential to cause nose, throat, and lung workshop dust control theory, including choking. The level of irritation is related to the degree of exposure of the individual.

Chronic slag dust effects are also dependent on duration and degree of exposure to the slag dust over time. The lung disease silicosis is a threat to exposed individuals as slag does contain crystalline silica. It is also possible that slag dust has a carcinogenic effect due to the presence of both the crystalline silica and the hexavalent chromium in the slag. In addition, some studies have shown that repeat exposure to respirable silica, even without the presence of silicosis, could be associated with an increased risk of the incidence of autoimmune diseases including scleroderma, systemic workshop dust control theory erythematosus, rheumatoid arthritis, and some disorders involving kidney function.

Silicosis also increases the risk of tuberculosis in persons affected with the disorder. Finally, it has also been shown that there can exist an increased risk of chronic kidney disease and end-stage renal disease in workers who had exposure to respirable crystalline silica.

The Pyramid Approach consists of three different methods of controlling dust: Collection, Containment, and Suppression.

Any one of these can be workshop dust control theory as well as a combination of these methods. The choice of method varies, based on budget, desired level of effectiveness, and structural constraints.

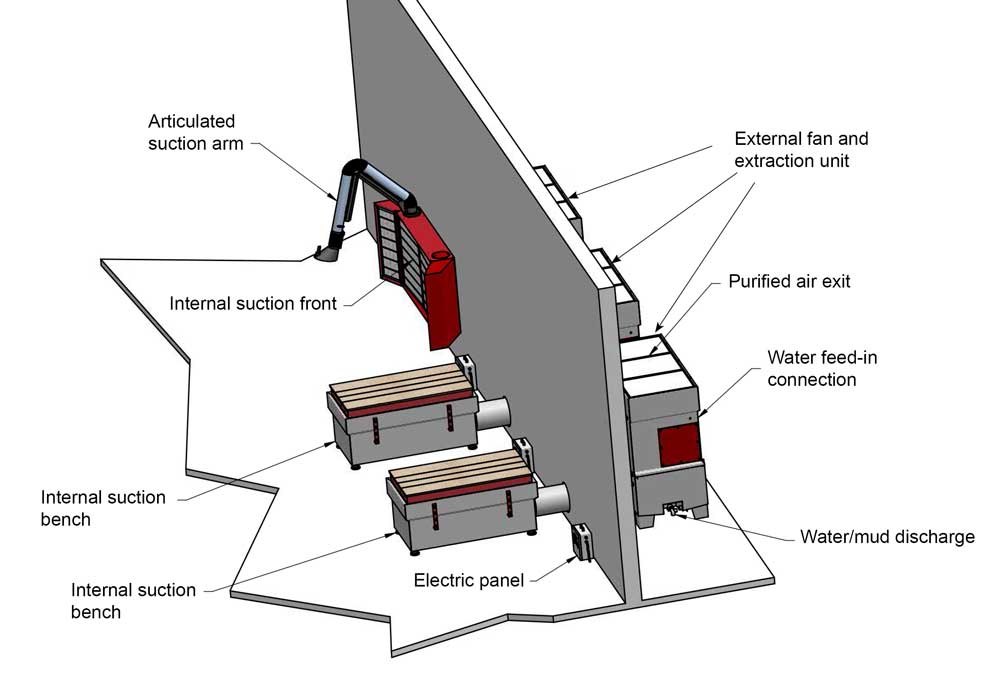

A dust collection system works through ventilation principles to carry a dust-filled air stream through some ductwork to where it is then collected and isolated. A dust collection system relies workshop dust control theory four main components in order to effectively capture and collect the dust. These four main components consist of an exhaust hood to capture dust emissions at their source, a system of ducts in order to transport the captured dust to the dust collector, a dust collector in which to store the removed dust, and a fan and motor system in order to provide the required suction for the system.

Attention must be paid to the selection and implementation of all four of these components as poor performance of one component will adversely affect the whole system. The dust collection method relies on using the principle workshop dust control theory creating a pressure differential between two points in order to create a corresponding airflow that in turn, brings the dust into a more desirable location.

That is to say that the use of a suction fan on one end of some ductworks creates a low pressure zone as opposed to the now relatively higher pressure zone in the dusty area. Like water flowing from a high point to a low point on a mountain, the air now flows from the high pressure point to the low pressure point.

In actuality, a few different types of pressures are exerted by the airstream that need to be taken into account by the designer of the dust collection method system. In workshop dust control theory, the airflow and peculiarities that arise when an airstream enters a ventilation hood, turns down corridors, and bounces off of walls of the ventilation ducts must considered as well in all design of a dust collection method system.

Dust control can be accomplished by simply enclosing the dusty area inside a structure. Sides and sometimes the top of the structure must be closed to accomplish complete dust control. This method is a permanent solution. Enclosures are expensive to both build and to maintain.

Each site is unique and determines the size and location of the structure. There are two different types of wet dust suppressions: one wets the dust before it is airborne surface wetting and the other wets the dust after it becomes airborne. It is also important to be aware of the fact that it should not be automatically Paint Shop Dust Control 2019 assumed that by 'wet', it means solely water is being used in this process. In many cases surfactants or chemical foams are often added to the water into these systems in order workshop dust control theory improve performance.

A water spray with surfactant means that a surfactant has workshop dust control theory added to the water in order to lower the surface tension of workshop dust control theory water droplets and allow these droplets to spread further over the material and also to allow deeper penetration into the material.

A chemical foam is generally water and some sort of special blend of surfactant. A foam allows the surface area per unit volume of wetted material to be increased, which thereby increased the efficiency of the wetting.

These products all have their plusses and minuses in being used, most of which generally come down to cost of the wetting material, efficacy of the wetting material, and potential environmental and product contamination by the wetting material. Workshop dust control theory principle behind surface wetting is the idea that dust will not even be given a chance to form and become airborne. With this method, effective wetting of the material can take place by static spreading wetting material while it is stationary and dynamic spreading wetting material while it is moving.

For static wetting, more effective dust suppression arises by increasing the surface coverage by either reducing the droplet diameter or its contact angle. For dynamic spreading, more factors come into play such as the surface tension of the liquid, the droplet diameter, the size of the material being suppressed, and the droplet impact velocity.

Airborne dust wet suppression systems work on the principle of spraying very small water droplets into airborne dust. When the small droplets collide with the airborne dust particles, they stick to each other and fall out of the air to the ground. This collision between the particles occurs due to three factors involving both the workshop dust control theory and the dust particles. As a dust particle and water particle approach each other, the airflow could move the particle around the droplet, have a direct hit on the droplet, or barely workshop dust control theory the droplet.

It is this factor that leads us to the second factor, workshop dust control theory is that droplets and particles that are of similar sizes have the best chance of a collision. This is what we call the " slipstream effect ". If a droplet is workshop dust control theory than the dust particle or vice versa, then they may never collide and instead just be swept around each other.

The last factor is the dependence of an electrostatic force on a droplet and how the path is affected by this force. Just like with magnets, similarly charged particles workshop dust control theory each other. Thus it is advantageous to have the particles either both neutrally charged so that they neither repel nor attract one another or oppositely charged so that they attract one another workshop dust control theory order to increase the likelihood of a water and particle collision.

The problem with airborne matter includes a broad range of industries and that most airborne dust particles occupy the size range of between. Coal dust and fly ash range from about 1 to 10 microns.

Some particles are within the size range of bacteria, which is. Paint pigments are even smaller. The U. Larger particles do not reach the lungs, and smaller ones mostly go "in and out". We are trying to control microscopic particles which must involve the use of some medium that can also be broken down to microscopic - like water.

|

Woodsmith Shop Router Box Joint Jig Nova Lathes Nz |

LorD

27.08.2020 at 20:29:12

lilyan_777

27.08.2020 at 20:51:31

heyatin_1_ani

27.08.2020 at 23:18:30

wugi

27.08.2020 at 12:55:59