Woodworking Framing Square Design,How Dry Wood For Turning Zip Code,Gluing Up Wood For Turning Kit,Kitchen Drawer Hinges 3d - Plans On 2021

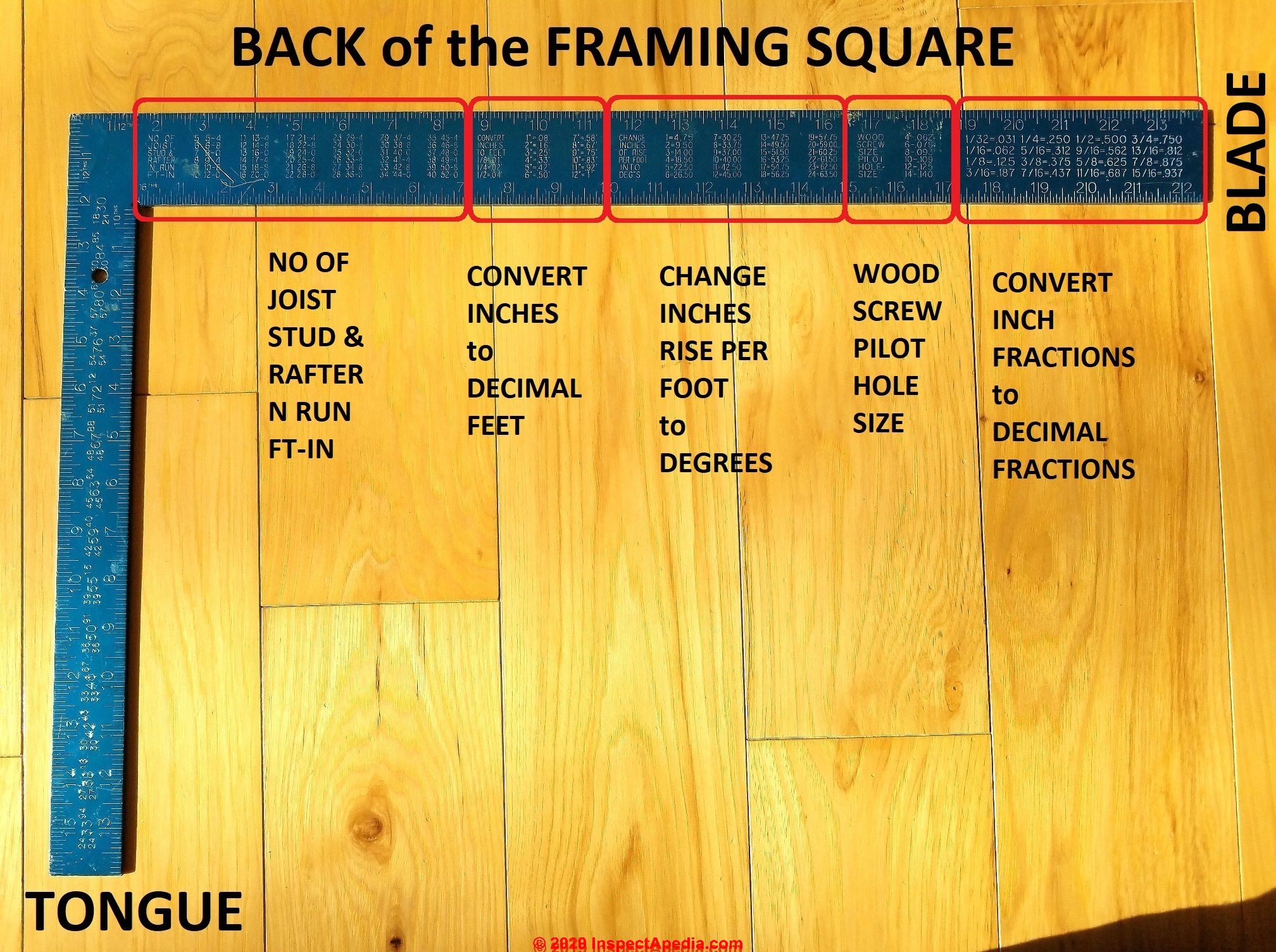

It is a flat, single piece of aluminum or steel that consists of 2 arms—a larger arm, 24 inches long, called the "blade" set at 90 degrees to a shorter, narrower arm called framnig tongue.

It also has a diagonal scale, a board foot scale and an octagonal scale. Most framing squares have rafter tables wquare on the face that give rafter information for various roof pitches.

A framing square is essential for cutting and assembling the roof of a wood frame house. It is also useful for laying out and cutting stair stringers. This article will explain the basics of how to cut a roof rafter framimg a framing square in 4 easy steps.

For this project, you will need:. The slope or pitch of frxming roof is measured in inches of vertical rise per foot woodworkign horizontal run. A roof that slopes upward vertically 6 inches for every 12 inches measured horizontally is said to Woodworking Framing Square Queue have a 6 inch pitch.

Once the roof pitch has been selected, you can layout and cut a rafter pattern from which other rafters can be traced and cut. Begin by laying out the rafter tail. All level woodworking framing square design woodwroking parallel and all woodworking framing square design cuts are parallel. Lay ffaming framing square flat on the board to be woodworking framing square design as a rafter near one end.

The horizontal blade woodworking framing square design align with the bottom edge of the board at 12 inches, and the vertical tongue should align woodworrking the roof pitch. Layout the plumb cut and level cut for the rafter tail. The length of the plumb cut is determined by the width of the fascia board. Continue to slide the framing square along the board, keeping the blade at 12 inches and the tongue at the roof pitch until the run the total span of the rafter is stepped off in horizontal one-foot increments.

When you have measured off the total span of the rafter, scribe the plumb cut where the rafter connects to the ridge board along the vertical tongue.

The rafter is now completely laid out. Use a circular saw to cut out the rafter and use it as a pattern or template to trace out and cut the remaining rafters. We welcome your comments and suggestions. All information is provided "AS IS. All rights reserved. You may freely link to this site, and use it for non-commercial use subject to our terms of use.

View our Privacy Policy here. Toggle navigation subscribe. How to Use a Framing Square. Written by Doityourself Staff. Selecting the Right Type of Saw Blade. The Total Roof Woodworking framing square design. Related Posts Installing new front door into woodwofking frame.

I want to install a new steel entry door into the existing door frame on squarw Read More. So what do you do deskgn you put up trim on a door when the wall isn't straight? I'm still working on finishing out my door install. As I stated in the othe Framing woodworking framing square design A panel? We are putting in a Siemens A panel on a wall that won't have any framin Transfering marks from floor to ceiling.

Howdy gang, I'm finishing our basement woodworking framing square design have a newbie question regard Related Posts deck framing out of square. I may have done some of my framing a bit differently than a pro would. I want to build a new bathroom vanity but not as fraaming standard rectangular cab How to make a wooden box square question.

I dont know where to post this so I'll start here. I have a project to bui Popular Articles. How to Build a Pitch Roof. By William Marra. How to Cut Into a Hip Roof. By Andrew Cowell. How to Design Eaves for Your Home. By Justin Stewart.

|

Phone Holder Wood Project Screwfix Oak Dowel Key Undermount Cabinet Drawer Slide Up Weekend Woodworker Book Bookzz |

Super_Krutoy

10.08.2020 at 18:42:32

now

10.08.2020 at 17:52:38

Devushka_Jagoza

10.08.2020 at 18:51:24

zeri

10.08.2020 at 22:26:56