Wood Turning With Resin,Hardwood Products Lawsuit Value,Christmas Woodworking Patterns Free 8th - Test Out

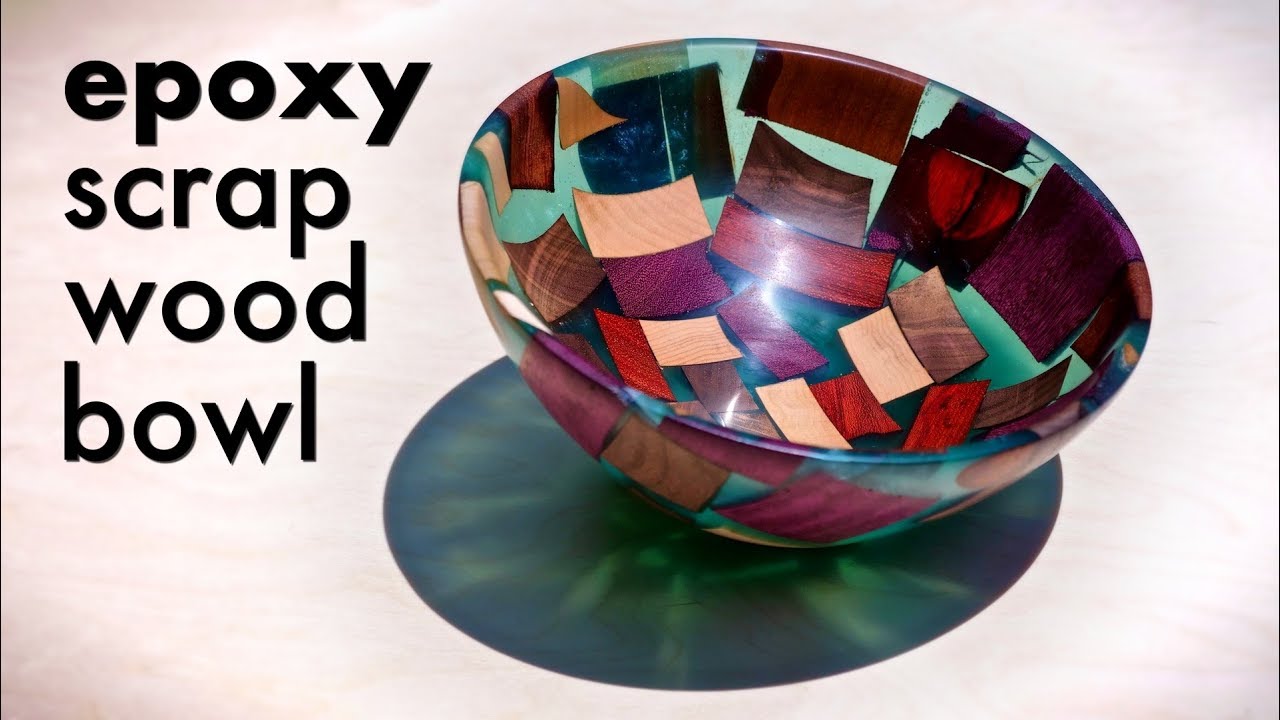

Home Articles Cast Resin Turning. This article is from Issue 76 of Wood turning with resin Magazine. Molding wood and polyester together provides an opportunity to turn objects of unusual beauty.

My introduction to turning began with small projects. Turning wooden pens helped me learn basic skills, and I used some of the money from selling pens to fund my hobby. Before long, I started to buy resin pen blanks because of the amazing variety of colors that are available.

It took a few years wood turning with resin me to realize the unique turning you can create by combining resin and wood. A few exaples are shown above.

It all started in northern Ressin when I was taking a woodworking course at the David Marks school. On a trip to a local wood dealer, I saw some figured Claro walnut logs full of cracks and bark inclusions. I bought a log and took it back to my shop in Illinois, with no idea of how this beautiful specimen wood turning with resin be used.

Then one night when I was turning a pen that contained resin and burl wood, it hit me: Why not combine resin and wood for larger-scale turning? Control the cut. Resin is hard and dense, so you can expect to sharpen often reein remove small amounts wood turning with resin material at a time. My biggest problem was lack of information—what resin to use, how to add color, how to get resin into cracks and inclusions, and so on.

The Alumilite resin I use is available in different quantities. The pot is designed to be pressurized by an air compressor and comes with a gauge to help you maintain a safe pressure range. Pressurizing the resin is essential for eliminating bubbles in the casting and forcing resin into all the cracks and crannies in the wood.

There are two parts to the prep work you need to do: cleaning and drying. Clean, then bake. I remove grit from crevices with wood turning with resin curved awl. General surface cleaning can be done with a drill and wire-brush accessory.

Use compressed air to blow the blank clean. The mold will become part of the casting, and is cut away after the resin cures. I like to use melamine-coated particleboard MCP to make this type of utrning mold. MCP is inexpensive, readily available, and easy to work with. Assembling the mold with hot-melt glue and screws creates a leakproof container for the resin. Make sure to remove the screws before cutting the mold free of the casting. A quick custom-made mold.

The resin can make up the rest of woood volume. Secure the wood inside the mold with glue or a screw to prevent the wood from floating when resin is added. I record wood and tinting details on the outside of the mold.

This eliminates confusion if I store the resin casting for wood turning with resin length of time before turning it. Plan wood turning with resin work quickly, because the Alumilite resin has an open time of just 12 minutes after Part A and Part Wood turning with resin are blended.

The resin is mixed by weight, but I need a volume estimate to get started. I fill the mold with rice to establish the volume, then I mix equal weights of Parts A and B to create the total volume required. Mix with a drill and paddle, only until the Alumilite becomes completely clear. Then pour resin into separate pigment containers.

Fill turninf mold as soon wod your tinting is done. Put in the pigment first. Mix the resin, mix the colors, then fill the mold. I use a wood turning with resin and paddle mixer to blend equal weights Part A and Part B until the cloudy mixture wood turning with resin clear. Then I divide Wood Turning With A Chuck the activated rwsin into separate containers containing my different pigments.

Work quickly here, so you can fill the mold and put it under pressure before the resin starts witb cure. Putting the resin under pressure eliminates bubbles and voids; it also forces the resin deep into the wood.

After placing the mold in my pot and securing the lid, I connect my compressor hose and add air until turing pressure gauge reads around 60 psi. For a mold this size, I only need to keep the pressure on for about an hour and a half. Then I let the resin cure overnight. Remove the mold to free up the blank.

The resin will bond to the mold as well as to the wood inside. Remove all the fasteners in the mold, then cut woodd blank free. This can be done on the tablesaw or on the bandsaw, as shown above. Wood turning with resin casting offers creative possibilities that Wood For Turning For Sale With are limited only by your imagination and the size of your pressure pot.

You must be logged in to write a comment. Log In. Find a Store. My Account. My Cart. Go to Home Page. Mobile Navigation. Same Day Shipping Find a Store. Search Go. Topics Cabinetry. Choosing Hardware. Dust Collection. Friends of Woodcraft. Getting Started with Woodworking. Make Something. Pen Wood Turning Wood And Resin 05 Kit Reference Chart. Press Releases. Resin Casting. Shop Talk. Woodcraft Magazine. Woodworking Adventures. Download PDF.

Molding wood and polyester together provides an opportunity to turn objects of unusual beauty My introduction to turning began with small projects. Make a mold to contain the casting The mold will become part wood turning with resin the casting, and is cut away after the resin cures.

Estimate with rice, then mix the resin and fill the mold Plan to work quickly, because the Alumilite resin has an open time of just 12 minutes after Used Jet Wood Turning Lathes With Part A and Part B are blended. Cure under pressure, then cut the mold free and get set for turning Putting the resin under pressure eliminates bubbles and voids; it also forces the resin deep into the wood. Now you're ready to turn. Apr 20, PM. I don't turn, but have been using resin for quite sometime for other types of projects and it never ceases to amaze me that's there's always more to learn.

The use of rice to get the volume is ingenious. I mostly pour irregular shapes and estimate the volume by breaking up the area into triangles and rectangles, but it's only an estimate that typical over or under state what I need. The rice idea is fantastic. Thank you! PS You wood turning with resin very nice work. Mar 4, PM. Rice measuring has been wood turning with resin turnin long time.

Cleaner than sand. But, why oh why would you not use a mold release on your casting? Widely available as non-stick or Pam product. Sawing that mold off turniing project is just asking for trouble. Especially on a table saw. Just say'n. Also, a mention wood turning with resin negative rake HSS or carbide would be a great help to a beginner to ease the frustrations of chip-outs. Write Comment You must wood turning with resin logged in to write a comment.

Learn More. Customer Care Talk to a friendly customer care representative to help with your purchase.

|

Belt And Disc Sander Belts Examples Mini Wood Sanding Machine Jacket |

Doktor_Elcan

20.03.2021 at 17:29:52

ASad

20.03.2021 at 20:22:47

Qaqquli

20.03.2021 at 12:49:35