Titebond Ultimate Wood Glue Msds Instructions,Cabinet Drawer Slides Bottom Mount Access,Indaux Kitchen Drawer Brackets View,Bessey Parallel Clamps 24 Inch Js - PDF Books

For Titebond Instant Bond glues, placing a few drops of acetone on the joint may cause the joint to loosen after absorption. Our literature states the shelf life of a majority of our wood glues as two years.

Titebond Polyurethane Glue has a one-year shelf life in an unopened container, but is useable as long as the glue remains fluid. Polyurethanes, however, are designed to react when exposed to moisture. Sometimes, they begin to cure, and solidify, after the bottle has been opened.

Most of our yellow and white glues, including Titebond Original and Titebond II, remain usable beyond two years. Should Titebond Original become thick and stringy, or Titebond II turn into an orange-colored gel, these changes signify that the glue is no longer usable. The minimum shelf life of Titebond III is stated as one two years. When stored appropriately at room temperature, Titebond III is expected to last beyond its stated shelf life.

If thickened, shake vigorously by firmly tapping bottle on a hard surface until product is restored to original form. For a complete list of Titebond wood glues, adhesives and sealants shelf lives click here.

This concept might Titebond 111 Ultimate Wood Glue Msds also be called "useable service life" or "storage life," and it necessarily refers to both the physical handling properties and the ability of the product to perform properly. When used in reference to wood glues, reaching the stated shelf Titebond Ultimate Wood Glue Msds Ii life does not mean that a product will "expire" or become unusable. Instead, we view the stated shelf life of most of our glues merely as a guideline to avoid potential aging concerns.

In reality, as long as products like Titebond Original, Titebond II and Titebond III remain fluid, without a drastic change in appearance, they will continue to perform as intended. It is possible to change the color of any of our water-based Titebond Wood Glues by adding either dyes or pigments. Water-soluble dyes such as food coloring or TransTints can be added directly to the wood glues with good mixing.

Powdered dyes or pigments should be mixed with a drop of Dawn dish detergent and a small amount of water to help prevent lumps in the pigment mix. Mix until smooth. Add no more than percent dye to keep from affecting bond strength of the adhesive. Before making your final color decision, be sure to let a sample of the dyed glue dry. When the mixtures dry, they may look different from the wet state. When different wood species are used in a project, it is important that all woods have the same moisture content.

Storing all the wood together in the same warm, dry location before beginning the project will help all the wood reach the same moisture content. To decrease the clamp time in a vacuum press, put a thick piece of wood into the vacuum bag to help absorb the moisture from the glue.

This technique is best utilized when laminating many thin veneers together because the water in the glue saturates the veneers. Glue joint "squeeze out" may make the area around the joint difficult to stain. Use masking tape to cover the areas that you do not want glue to soak into. The sections that were masked will be free of stain-resisting glue when the masking tape is removed. Although good joint design minimizes the need for gluing end grain, sometimes end grain joints are unavoidable.

The strength of end grain joints can be improved if the "open" end grain is first sized. A sizing mixture may be made by mixing one part to two parts water to one part glue. Place the sizing mixture on the end grain. Let it soak in for no more than two minutes, and then continue with a regular application of glue. Use a small artist's brush to coat the surface with glue before applying homemade wood filler. Doing this will assure that the surface is wet enough to encourage adhesion.

Otherwise the wood filler mix may be too dry to adhere well to the surface to which it is being applied. Stepped joints typically result when pieces of wood of different moisture contents are edge glued together in making a tabletop or cabinet door. It is important to be sure that all the wood for a given project is at the same moisture content before beginning a project.

Allowing the wood to acclimate or sit exposed in your shop for a week or two is one way to be sure each piece of wood has a similar moisture content. When working with woods that are high in tannic acid or are considered oily, wiping the joints with acetone before gluing them up ensures a good bond. Acetone clears the contaminants from the wood's pores on the bonding surface and dries quickly without leaving any residue.

A good bonding surface can also be achieved by sanding or planing the wood just before gluing the joints. Water-based wood glues such as Titebond Original or Titebond II build strength in a joint as they lose moisture into the surrounding wood. This moisture causes the wood on both sides of the bondline to swell slightly. If the project is planed or sanded before this swelling disappears, the high moisture wood near the joint will continue to dry and will shrink slightly compared to the rest of the wood.

Allow your project to dry for several days before sanding or planing. Titebond Liquid Hide Glue is very sensitive to humidity, therefore it is often hard to tell when to take off your clamps. The best way to determine your clamp time is to place a scrap piece of wood with Liquid Hide Glue spread on it next to your newly glued and clamped piece.

When the glue on the scrap piece of wood is dry, you can take your clamps off. Be sure to wait at least 24 hours before you stress the joints. Titebond TiteGrab. Titebond Step. Woodworking Glues A collection of informative resources to answer most questions. Frequently Asked Questions Can high moisture wood be glued? Ensure the surface is clean and dry of any material such as oil or dirt.

Yes, not designed for continuous water submersion and installing rear view mirrors. Instant Bond is designed for interior usage. Frequently Asked Questions What is the "crackling effect"? Frequently Asked Questions How do I clean up wet glue or remove dried glue? Frequently Asked Questions What is the best way to disassemble a glue joint?

Did you know? How to properly add dye to Titebond Wood Glues. Special consideration must be given to projects involving different wood species. Decrease clamping time using a vacuum press. When gluing, use masking tape to cover parts of your piece that will be stained later. Get good results gluing end grain joints. Ensuring that homemade wood fillers adhere to the surface. Prevent "stepped" joints in your projects. Freezing may not affect the function of the product but may cause it to thicken.

Agitation should restore product to original form. Because of variances in the surfaces of treated lumber, it is a good idea to test for adhesion.

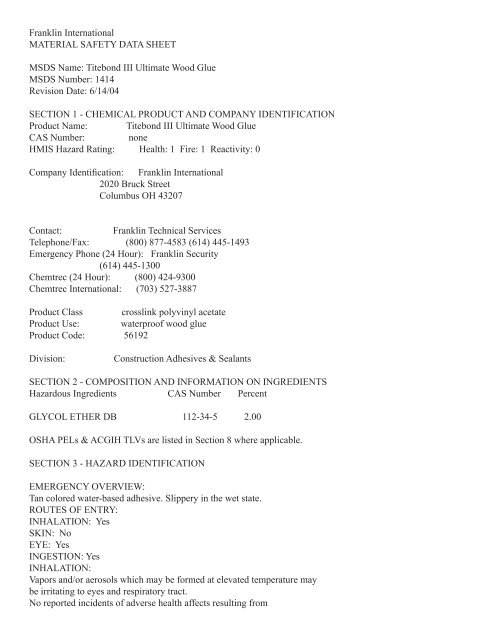

For best results gluing exotic or oily woods, such as Ipe and Teak, please contact our Technical Support Team at Read MSDS before use. Physical Properties Type Cross-linking polyvinyl acetate. Contains aluminum chloride. Do not swallow. Do not allow eye contact or prolonged skin contact. If eye contact occurs, flush with water for 15 minutes. Wash skin contact areas with soap and water. If irritation from eye or skin contact persists, contact physician. For additional information, refer to Safety Data Sheet.

|

Baseball Bat Blanks Hickory Light Turning Stocks Into Bonds 04 |

220

11.07.2021 at 22:30:48

Ledy_MamedGunesli

11.07.2021 at 12:13:52

farcury

11.07.2021 at 21:16:15

ELNUR

11.07.2021 at 20:31:17