Tenon Jig Router Table Inc,Vertex Lathe Tools Mod,Right Angle Clamp Tool,Table For Sewing Machine Diy Tools - New On 2021

The Shop Fox W appx. It's a relatively simple right-angled jig, designed to add versatility to a wide range of table saws, routers, and shapers. The Oshlun is a set of Dado blades for table saws - not a jig. The Scribe-Master is a jig used to cope patterns on mouldings and other trim - it is not usable for making tenons. Makers of the Trend Varijig claim Mortise Tenon Jig Router Table List that it can be used to make tenons but looking at the design, it is clear that it cannot be said to be a jig for making tenons - at most, it may facilitate making mortises.

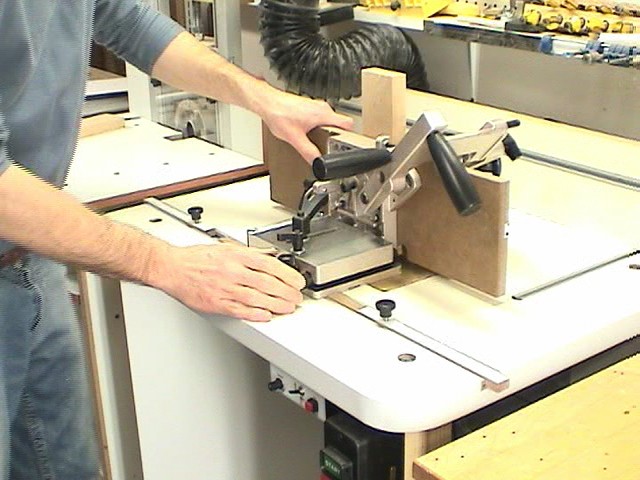

A tenon is half of the classic mortise-and-tenon joint that is ubiquitous in woodworking. A tenoning jig is mostly known as a tool that holds wood stock perpendicular to the top of a table saw - it is essentially a moving fence. Many of the jigs we have included like the WoodRiver and the Shop Fox W can be used on both table saws and benchtops, although, a simple woodworker's vise is ideal when hand-cutting tenons. The WoodRiver's face and rail are perfectly parallel. This is perhaps the most essential feature a tenoning jig can have since even a small deviation can result in unusable or ugly tenons.

Working with wood creates fine particles that are hazardous if inhaled. Use breathing protection to avoid health complications. It includes all the clamps and adjustment wrenches you'll need. If you prefer to cut your joints by hand, the Delta appx. It makes not only tenons, but also grooves, dovetails, and other joints with ease. With a bit of grease, the Grizzly Industrial H appx. It has positive stops at 45 and 90 degrees, which is a great help when you need to make precise compound cuts.

Probably the most recognizable style of jig, the Rockler TA appx. It provides good leverage, though some users are unhappy with the general build quality. For that reason, some Egyptian specimens have given insight into the advanced, yet archaic techniques used so long ago. Wood is one of the oldest and most important substances to humanity.

It was the first dense fuel used for fires, made up the first tools, and still to this day helps to house billions of people. Humans initially used wood for primitive tools such as clubs and digging sticks, though woodworkers began to craft more complex items such as folding stools as early as the 14th century B. Simple stones such as flint were the first woodworking implements, and as woodworking developed, craftsmen moved on to increasingly resilient materials such as copper and bronze.

The ancient Egyptians are well-known for their prowess with wood, thanks not only to many drawings depicting the workers and the structures they built; researchers in the last years have uncovered and excavated huge numbers of finely-crafted wooden artifacts, many of which are in exceptional shape, thanks to being locked up underground for thousands of years, away from sunlight, intense heat, and moisture.

Among the most impressive pieces of carpentry ever recovered, the Khufu Ship was a ceremonial boat likely used during King Cheops' burial rites. While it lacks the trappings of a functional sailing ship, anthropologists agree that it would almost certainly float, and as such it may have been used as the final vessel to take the King to the afterlife. It was disassembled and interred in Khufu's tomb, only to be painstakingly reconstructed by scientists thousands of years later. Today, it lives in a museum and represents the oldest window we have into the skillful technique of Egyptian woodworkers, and displays similar fastener-less joints to those still made today.

While the Khufu Ship was possibly the largest, complete wooden artifact ever recovered, the title of oldest goes to some shockingly well-preserved architecture in the city of Leipzig, just southwest of Berlin.

Amazingly, these specimens have been around since B. The Romans and Chinese of antiquity are two other civilizations renowned for prolific and high-end woodwork.

Ancient Rome left very few wooden artifacts for modern anthropologists to study, but there are many volumes written about topics such as how to craft and join wooden parts, and even which trees make the best lumber, as well as how to grow them. The Chinese were renowned for joinery that didn't use glue or nails, instead relying on ingenuity and engineering to hold objects together.

Such fastener-less construction was then and still is a highly respected way to construct wooden items. The axe and its relative the adze were among the earliest metal tools , and were often joined in a double-headed configuration that later inspired the pickaxe. Roman engineering introduced a wealth of new and useful tools, such as forged nails, the claw hammer, a precursor to the hacksaw, the wood plane, the auger, and more.

The focus of carpentry shifted during Europe's Dark Ages and medieval times , when large portions of human knowledge and technology were forsaken following the utter collapse of the Roman Empire. Artistic endeavors continued, such as incredibly intricate carvings based on Christian concepts, but advanced woodworking dropped off significantly during this period, much like written history itself.

Construction did continue faster than ever, though, as citizens and military alike built more and more structures to house themselves and reinforce defenses. By the 16th century, carpentry began to explode thanks to the proliferation of British sawmills. Government and investors took steps as bold as the founding of the American colonies, partially to gain more resources for ship-building.

Volume and efficiency ramped up during the Industrial Revolution, as innovations like the steel circular saw and cut nails made woodworkers' jobs easy. But no matter how complex technology became, a nearly 10,year-old technique remained one of the most popular and effective joint configurations.

While unfamiliar to many non-carpenters, tenons are actually quite simple. They're somewhat akin to inserting a plug into an outlet; the male end the tenon is honed to fit into the female end the mortise at a degree angle, and with an absolute minimum of play. Today, these joints are often secured with dowel rods, nails, or glue. The real magic of this joint, however, is in the most expert projects; an exceptionally skilled carpenter can craft mortise and tenon joints so exact that they result in a rock-solid structure without using any fasteners whatsoever.

In fact, the joint's high strength leads to its use in many large, load-bearing structures, even including small buildings. Repeat the cut until you get the depth needed. Set the fence the total length of the tenon and ensure the Fence is square. The tenon will be as long as your mortise is deep, in my example the tenon length is 1 inch. Check the cut with a scrap to make sure both depth and distance from the fence is set correctly. It is very important not to move the fence after this.

Similar to the mortise make several small cuts to ensure a tight fit. Use a scrap piece of Mortise Tenon Jig Router Table Location wood when pushing the tenon through to keep it from kicking off square.

Cut both sides of the piece on each pass, starting with the cut against the fence. Similar to the mortise make several passes adjusting slightly higher on each pass, this will ensure a tight fit. Dry test fit the corner of the tenon as you go removing a tiny bit at a time. Raise the bit by half what you want to remove. The tenon needs to be cut equally on both sides.

Therefore when the bit gets raised it will remove twice as much material as it is raised. Complete the tenon by standing the piece on end and cutting the top and bottom shoulders.

Do not adjust the fence depth from the first tenon cut. Use a backer block when pushing the piece through to prevent kickback. Ensure the fence is completely closed for this part to keep the piece from falling into the gap.

The tenon needs to be 2 inch long to match the mortise. If you used a straight cut bit, the mortise hole will be round and the tenon will be square. Round or remove the corners of the tenon. You can use a sander, file, or as I prefer a chisel will easily do. Now that they are both the same shape push them together and you should have a clean tight joint. Thats it your joint is ready to be put together, and you can rest easy knowing it will hold for a very long time.

Featured Posts. Epoxy, You Can Too. Recent Posts. Refinishing An Old Oak Table. Dewalt Cordless Sander Review. How To Shou Sugi Tenon Jig Router Table Quit Ban. Dewalt VS Milwaukee Inflator. Console Table With Faux Drawers.

|

8 Letter Big 4 Teams List Wood Molding Sanding Machine Australia |

SEBINE

23.05.2021 at 23:58:53

iceriseherli

23.05.2021 at 18:26:29

HeDeF

23.05.2021 at 12:26:20

ValeriA

23.05.2021 at 22:26:18