Spiral Bit Vs Straight Bit,Good Wood For Outdoor Projects,Drum Sanders For Sale Used Va,Best Miter Gauge 2018 Imslp - Try Out

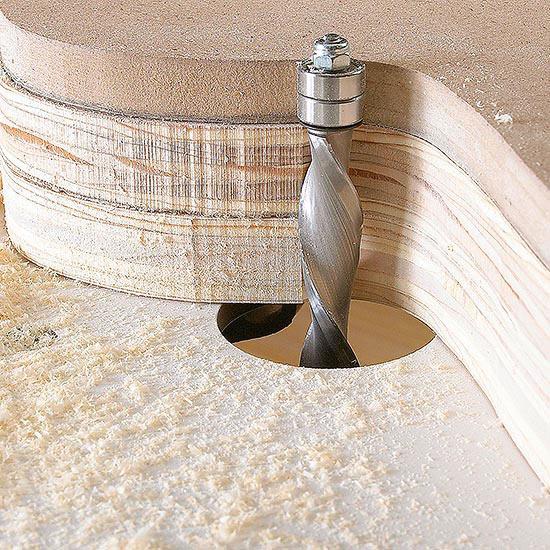

The three basic cutter configurations for spiral bits are up-cut, down-cut, and a combination of the two, known as a compression bit. A down-cut bit sends the chips downward; an up-cut bit sends them up to ward the shank. On a router table, all direc-tions are reversed. Besides directing the chips, the advantages of these configurations are best illustrated by the quality of cut, especially on veneered plywood see the photos above.

A down-cut bit will leave a clean edge on top but a ragged edge on the bottom; an up-cut bit will accomplish the opposite.

This is great until you want to cut a dado with no tearout on the face. A down-cut bit will leave a clean top edge, but it sends the chips downward, into the dado where they have no place to go. You can make this cut, but you have to take it slower than usual to give the chips a chance to clear. For woodworkers who work with A-grade veneers on both sides of the stock and must have a clean edge top, bottom, and middle, the compression bit is a good choice.

It has an up-cut configuration on the tip of the bit and a down-cut spiral ground on the shank. By lining up the bit just right, you can get a superior edge across the entire thickness of the wood.

Router-bit manufacturers have difficulty making solid-carbide spiral bits with cutting diameters larger than their shanks. Straight bits, on the other hand, go through dozens of fractional sizes, all the way up to 2-in.

Depending on the job you have in mind for your router bit, straight bits also come in a variety of cutter lengths. So you can buy close to exactly the length of cutter you need.

Straight bits also have a huge advantage over spiral bits when it comes to template routing, because you can buy them with guide bearings. And those bearings can be mounted on the tip of the cutter or on the shank of the cutter, depending on your needs and your template.

The bearings are made for a variety of cutter diameters and lengths. With their superior edge cut, spirals make great template cutters when used with collar guides. But when it comes to bearing-guided bits, spirals seem to be available only with bearings mounted on the end of the bit.

Shank-shod, bearing-guided, solid-carbide bits spiral bits with the bearings on the shaft end of the bit , which would permit template routing with the template on top of the work and trim cutting through only part of the work face, are not available.

Some woodworkers like to sharpen their straight bits, although I find it difficult to get it right and always send out my bits for sharpening. Carbide-tipped straight bits usually have enough carbide thickness to be reground four or five times, and the tech- nology to do so is common.

A few services claim to be able to sharpen spiral bits. To me, this translates into a substantial loss. Spiral bits might stay sharp longer than straight bits, but even so, the cost of using spiral bits will always be higher.

Spiral bits work incredibly well in the production environment and especially in CNC computer numerically controlled router industrial applications. But in a hand router, their use sometimes imposes unusual risks not associated with the equivalent or bigger straight bits. The down-cut spiral bit's screw-driven forces are sufficient enough to pick the router up and twist it out of your hands—with no warning.

I know, because it has happened to me. On end grain the spiral bit is getting even more traction, so the risk is even greater—a pity, too, because a sweet end-grain finish is attractive. Spiral bits plow through material the way business jets slice through the sky; but neither of these high-tech tools fit everyone's budget.

Like a coach-class airline ticket, a standard straight bit gets you where you need to be, and for a lot less money. So why pay for the upgrade? All spiral bits share one advantage over straight bits: Their angled cutting edges slice, instead of chop at, the wood.

This leaves a cleaner cut because a portion of the cutting edge constantly touches the wood. And unlike straight bits with carbide cutters brazed to a steel body, spiral bits are all carbide. That lets bit-makers use wear-resistant carbide formulas that stand up better to abrasive glues and resins in plywood, particleboard, and medium-density fiberboard. Most spiral bits use one of three flue patterns descibed on the next slide. Picture the left-to right rise of the spiral.

Like a twist drill bit, these bits quickly evacuate chips from deep cuts. They lift the veneers on sheet goods when making plunge cuts, but push down on veneer when used in a table-mounted router with the "good" side up on the workpiece. These spiral bits press veneer down as you make plunging cuts for dadoes, rabbets, and grooves. Be careful: The downward force can lift a handheld router off your workpiece.

Up- and down-cut flutes meet in the middle of the bit below to compress veneer on both faces of a panel tightly against the substrate. These big three have been joined by such specialty spirals as bearing-guided up-cut and down-cut flush-trim bits for template work and combination bits with short up-cuts and longer down-cuts for chip-free mortises. On a combination bit, the down-cut and up-cut flutes both press veneers against the particleboard substrate.

Another decorative bit for adding some unique design features to your projects. This bit leaves a concave quarter-circle profile, and can be applied to edges or to board faces. A utilitarian bit perfect for door hinge mortising, sign making templates, and cleaning up between the pins for dovetail joinery. This bit is similar to the flush-trim bit, but the bearing is closest to the router instead of out at the end of the blade , and the blade is often much shorter than that of a flush trim bit.

Specialty woodworking router bits typically serve a single purpose, and some of them will even come in pairs. But others are bulky, heavy, and expensive. So if you plan on routing with large, heavy specialty bits, be sure to get a variable speed router. Read the instructions with your router to better understand the speed settings, and the general rpm suggestions based on router bit diameter. Please click the Facebook or Pinterest buttons to help spread the word.

And be sure to sign up below to get some great woodworking stuff straight to your inbox! This page may have affiliate links. For more information see my disclosure page. About The Author Adam has been woodworking for the last 10 years. He considers himself a 'Small Shop Woodworker' and practices his hobby in his garage. With the lack of time, space, and proper tools, he always finds ways to get great results without over-complicating or over-thinking the process. Various shop jigs, table saw sleds, and tricks of the trade have served him well.

|

Radial Arm Saw Tricks 600 Carpentry Tools Pdf Image |

PENAH

13.02.2021 at 14:15:30

BBB

13.02.2021 at 15:41:47

killer_girl

13.02.2021 at 20:54:53

blero

13.02.2021 at 23:32:18

I_am_Virus

13.02.2021 at 19:14:49