Pdc Machines Inc Usa,Best Tongue And Groove Router Bits You,Christmas Woodworking Projects Free 40,Diy Wood Headboard With Lights Zipper - 2021 Feature

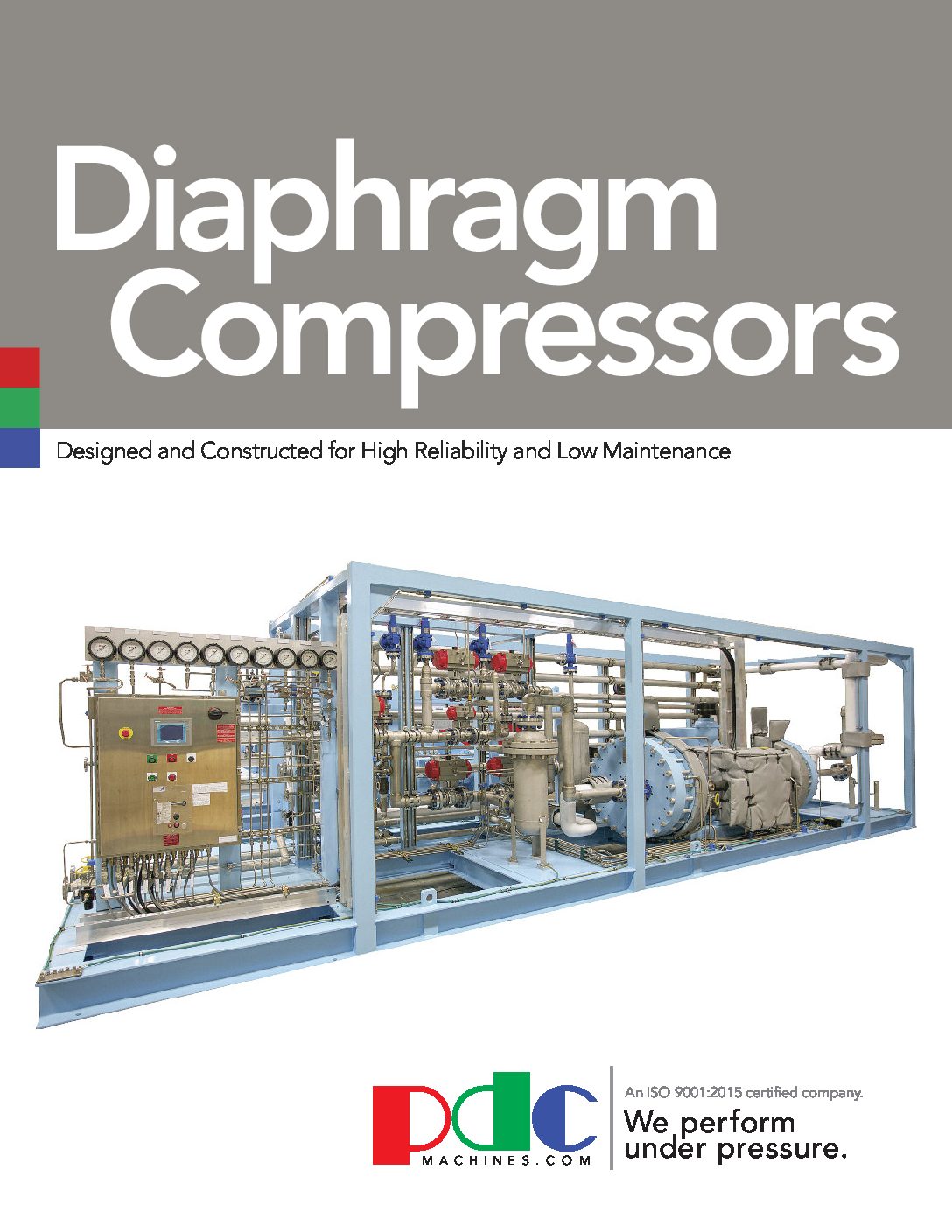

Containerization At the request of our customers, PDC Machines can package our compressors and customers equipment and instrumentation inside a container. Highly reactive gases service For compression of oxygen , fluorine, silane, phosphine and other highly reactive gases, PDC Machines performs rigorous cleaning procedures in a clean, dust-free environment.

We use fire-resistant oil for the hydraulic system. We construct the process side diaphragm as well as the inner and outer check valve components.

A diaphragm compressor is a positive displacement machine which consists of a hydraulic system and a gas compression system. Diaphragm compressors are somewhat traditional in the sense that the hydraulic system uses a linear reciprocating piston attached to a crank shaft that is driven by an electric motor. The hydraulic piston travels through a cylinder which moves a column of oil. This oil is used to lubricate the lower end running gear and to energize the gas process system.

The gas processing system consists of the gas head assembly, three metal diaphragm plates and the compressor check valves. Triple metal diaphragm compressors are unique because they are leak-free and non-contaminating since they do not utilize dynamic seals and the diaphragm set completely isolates the process gas from the hydraulic system.

Each compressor also includes a leak detection system that monitors the integrity of the diaphragms and static o-rings. Breaches in these components can signal an alarm and or automatically shut down the compressor. The triple diaphragm set ensures that the process gas is completely isolated from the hydraulic oil.

The compressor does not use dynamic seals eliminating the potential for seal particulate to be imparted to the gas stream. Filters and oil removal systems are not necessary — Hydraulic oil cannot migrate into the process gas. Our metallic diaphragm compressors can achieve typical compression ratios up to for certain models. All aspects of diaphragm compressor design are intended to enhance component life, improve operability and reduce and simplify maintenance.

Diaphragm cavity contours, which control stress in the diaphragms, are carefully controlled to provide uniform stress distribution. Special manufacturing processing is used on the diaphragm surfaces to enhance fatigue life. Many of our customers have experienced continuous running times of 10, to 40, hours between routine maintenance minimizing the need for spare parts replacement.

PDC compressors are capable of sub atmospheric as well as high suction pressures. Compressors can be used in in applications requiring low or high compression ratios. And for applications requiring intermittent or continuous service duty.

The hydraulic system is designed in such a way as to assure uniform diaphragm deflection, prevent knocks, vibration, cavitation and yield smooth, quiet compressor operation. Our diaphragm compressors use static seals. There is no migration of gas to the crankcase as such the crankcase does not require purging or venting. The gas system integrity is monitored to preclude leakage of gas to the atmosphere.

We use non-flammable hydraulic fluid and all process-wetted components which are constructed from corrosion-resistant materials for processing of corrosive or oxidizing gases for safe operation and which will prolong the life of maintenance components. The compressor is automatically re-primed at start-up. Manual start-up requires an experienced compressor technician to be present all the time to re-prime the compressor. Incorrect priming will cavitate the compressor and damage the heads, bolts, diaphragms, o-rings, process and hydraulic system.

PDC compressors use a heavy flywheel to provide energy. In addition, Duplex and two-stage diaphragm compressors can be horizontally opposed designs to further reduce horsepower requirements and energy usage.

We provide an automatic, positive displacement gear pump. Priming is crankshaft driven Pdc Machines Inc Inc and automatic upon start up. This eliminates priming problems that are typically associated with gravity fed pumps.

PDC Machines provides a plunger type injection system on all motor driven diaphragm units. The injectors are also crank driven and precisely meter hydraulic fluid flow during the operation of the compressor.

The deflection and resultant stresses in the metal diaphragms are controlled by carefully designed cavity contours. We use state of the art design and analysis tools as well as cutting edge programs to model these. At PDC Machines we machine process heads from a variety of materials for process gas compatibility. The diaphragm set consists of three plates.

The upper or process side, the lower or hydraulic side and the middle diaphragm. The middle diaphragm is brass to preclude galling. PDC has reopened production as of today, March 30 and is processing orders as per the commonwealths guidelines on life sustaining business. As such, PDC has instituted strict safety, distance and cleanliness guidelines for our production teams across our 3 manufacturing facilities. All staff who can work remote are doing so since early March and will continue to do so for the foreseeable future.

PDC Machines production timelines may be affected. Our staff will be reaching out to inform of the impact to your project. As always if you have any questions, please contact your PDC sales staff or customer service staff for information.

Our operations in Korea, Japan, most of China and in many other countries are currently open in a similar fashion and serving customers. The well-being of our employees and customers is our top priority so we have decided to close our production facility in Warminster, PA to limit the spread of the Coronavirus COVID These closures will go into effect from Tuesday, March 17 through Friday, March Customers can continue to request information, pricing, and place orders.

As a responsible corporate citizen, we are taking the imminently necessary steps, including deploying many employees to work from home, social distancing, closure of production and assembly, and additional safety and cleaning steps to help protect and support our employees and customers.

PDC will operate on limited capacity to process spare parts orders- please contact your PDC sales staff or customer service staff for information.

Email Voice: Fax: PDC Machines, Inc. If you require any technical support, pls complete the form below. This will help us expedite our technical support. Contact: Jarrod Eveland Phone: x Email. Operational Instructions Our customer service staff can provide you with specific instructions for how your machine should operate and sound.

Technical Specifications Machine specific specifications can be provided verbally or we can email you PDF drawings of what you need right away.

Please have the spare parts part numbers and description available when reaching out to me.

|

Best Hand Saw For Ripping Wood Gear Brick Moulding Router Bit Number |

fb

21.09.2020 at 10:25:34

bakililar

21.09.2020 at 14:13:46

Simpson

21.09.2020 at 10:32:32

ESSE

21.09.2020 at 22:26:43