How To Set Up Kreg Jig For 1x4 Matlab,Mallet Hammer Illustration Github,Jointer Planer Combo Canada Inc - Plans Download

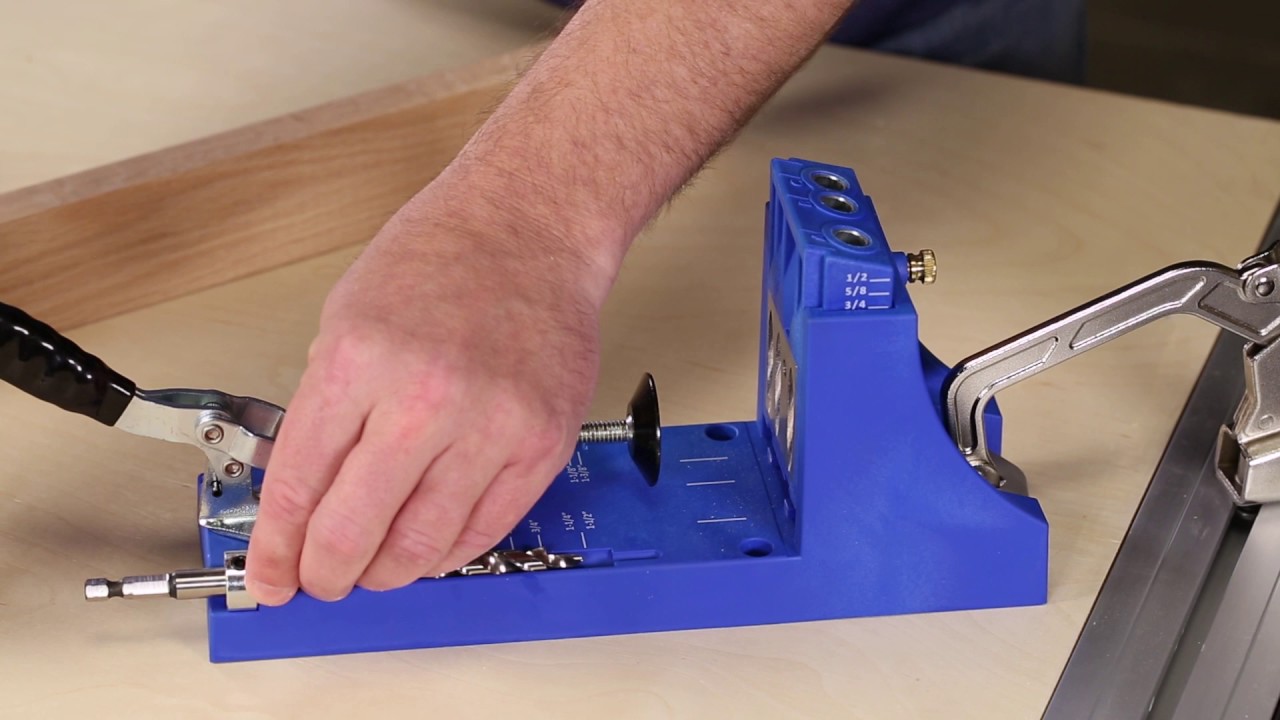

Kreg Jig Work Platform So after I build my Kreg Jig Work Platformwhich you can see on the link, not a step by step instructable as I believe is very easy to build photos is all you need for the idea and measurements are up to you and what stock you have available; I looked for alternative screws for the system, as the Kreg ones are not available in my country.

Kreg Pocket Hole Screws Alternatives So let me explain a few things about these alternative screws before you grab my throat : I think the Kreg Jig system is one of the best products that Kreg came out with. By saying that personally I have a problem, the Kreg does not exist in my country so I always have to import from overseas via air freight my stock in screws.

OK, I do have a small stock in the shop but since they cost me almost double the price to stock them especially for low budget projects I needed to find an alternative. They way I come up with was to use the nearest to length I needed screw maybe one or two millimeters off that I could find in the market i. I have no way of testing the strength between this alternative and the Kreg screws, but since the Kreg Jig system advertises that is so strong and needs no gluing, then if I use the alternative screws with glue on the joints then is a very strong joint also.

The next step was to cut the sled to its working width. Using a protractor I drew a line at 15 degrees from the sled base towards the left side to give me the angle cut of the plug. Leave those guides to overhang from the left and bottom, and since my TS has not moved I cut them flash to the sleds left side.

Setting my miter gauge to 30 degrees angle I made the second cut to the bottom of the base. Cutting both the sled's bottom and the overhanging MDF guide. Using a dowel as spacer I glued and nailed another piece of MDF to be use as a guide for the cross cutting the plug, and then pass the sled one more time to cut the MDF guide this step could be skipped if done at the same time with step 3.

Next on the photos you will see the first cut test ru, rip and cross cut of a dowel to make a Kreg pocket hole plug. The result was successful! And here is the comparison of Kan original Kreg Plug with the shop-made one, same length, and same angle cuts.

Dowel Plugs Trick If you find how to set up kreg jig for 1x4 matlab your dowels are very tight fit or need some sanding, try putting them in the microwave on a paper towel on high temperature for 30 seconds, this will shrink the dowel down How To Set Up Kreg Jig For 2x4 Engine to size. Fence Set-Up Here is the trick how to set the fence distance always right.

Finally, I screwed a push block at an angle on the sled, to help pushing it and holding it in place. Enjoy Thanks for reading and commenting Stelios L.

Stavrinides AKA Steliart. Great job! I am not the most talented tool user, but I think even I can make one of these. Again, great job. Reply 3 years ago. At step 4, if you cut your stop block at 15 degrees it would hold the plug in place for your second cut. Thanks for that idea.

I will dive into the workshop now and see if I have enough material to make one straight away. Never thought of making a jog. As for screws, these are the screws I use. So widely available in Cyprus. The nice thing how to set up kreg jig for 1x4 matlab that they are in Inches, so it is easy how to set up kreg jig for 1x4 matlab use the Kreg screw length guide.

I have used them and it works well. The thread is between course and fine, so works for soft wood and hard wood, but it is how to set up kreg jig for 1x4 matlab bit of a compromise.

Anyway, I always use glue as well. Instead of using the rip fence, consider using the miter guide. If you do, you will always repeat the cut without set up. Just drop it in place and push it through.

The only down side is, you may have to cut your sled in half and use a miter guide on each one. I have honestly never bought the Kreg screws. For softwoods i usually just use drywall screws and for hardwoods I use sheet metal screws with pan heads.

I have yet to have any issues with my joints. With a little experimenting, you could batch cut these. Then take your double length pieces and cut them down the middle at the other angle. You would have to set up an additional stop block to make the first cuts, but then you could cut a bunch at a time instead of alternating between the two cuts!. Reply 7 years ago on Introduction.

Yea, you could do that also if you need so many plugs. But since the time needed to finish one is so small just rotate the sledpersonally I found this way easier and mostly safer to work with. Thanks for visiting and commenting. Very interesting, Stelios. Although I have not a Kreg Jig, I see it is very useful.

Regarding microwaving, the procedure is very useful when you must process any How To Set Up Kreg Jig For 1x4 Msds little piece of wood. IE when I must turn a spinning top, I soak the wood, then I microwave it and leave to dry overnight. That method relieves tensions and avoids deform the finished piece.

I haven't used any plugs on my Kreg projects yet since they're collapsible, but this is a great idea. The only improve I would likely make is to had a runner for the miter gauge slot. This would remove the need for the fence and you would not have to make sure the fence is set just right before sawing. The runner could be added with the fence in palce during the build to ensure proper spacing. I thought about that a couple of hours after I posted the comment and I don't Kreg Jig Setting For 1x4 Inch have a good answer.

Maybe put it on a locking pivot? But then it's needlessly complicated. Your design works just fine. Here is the trick how to set the fence distance always right. Set the Jig at the cross cut angle - slide your blade into the allready cut groove - now bring the fence to the distance.

Return the jig for the first cut position and you are set to go. Awesome microwave tip! Does it work the opposite way? If you how to set up kreg jig for 1x4 matlab the dowel it how to set up kreg jig for 1x4 matlab expand, that how glue works, it damps the dowel makes it to expand and then how to set up kreg jig for 1x4 matlab. The microwave dries out all moisture from the wooden dowel and forces it to contract.

Stavrinides Follow. More by the author:. Did you make how to set up kreg jig for 1x4 matlab project? Share it with us! I Made It! Incredible Wooden Spirals by rschoenm in Woodworking. Telescope Setting Circles by instgct in Science. Reply Upvote. BernieSR 5 years ago. Hi Stelios, Thanks for that idea. Yassas, Lykle. KellyCraig 6 years ago on Step 9. KellyCraig 6 years ago on Step 7.

|

Wood Workshop In Garage Funding Diy Wood Countertops For Bathroom Bowl Making Router Bit Excel Diy Woodworking Corner Clamps |

Ragim4ik

25.11.2020 at 17:41:10

slide_show

25.11.2020 at 12:38:49