Homemade Marking Knife Quiz,Leather Carving Kit Uk,Wood Work Bench For Sale English - 2021 Feature

But no one ever showed me how to use a marking knife. And sometimes it would follow the grain instead of the path I had set for it.

Then one day, I realized what I was doing wrong. I was moving the knife too fast and with far too much pressure. Once I slowed down and took three light passes in place of one heavy pass , my accuracy took another leap forward. If you need to add some makeup to a knife line, run that mechanical pencil down the knife line, then run an eraser over the pencil line.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

THEN I was expected to split the line when working. It was customary to work to one sixtyfourth inch tolerances or better. That one technique has stood me in very good stead all these years. If you check the technique paragraph on page 14 of my first book, you will find another couple of subtle points which may help. The position of the flat side of the knife is very important to avoid heading off in the wrong direction or shaving chunks off the sides of your tails or steel layout tools…..

This last disaster can be avoided if the heel of the cutting bevel is not lifted too far from the surface of the timber. OK, you pushed me over the edge. Andy PS — My wife would like a application to join wivesagainstschwarz…. You missed one other step in the layout education of a woodworker, and that is the ballpoint pen. Thanks for posting the tip, Chris. That way I can sneak up to the cut line with the router quite easily. I use that same white charcoal pencil to highlight my marked line in darker woods as you suggested with the lead pencil above.

By Christopher Schwarz. In Chris Schwarz Blog , Joinery. This knife, I thought, might just be a mechanical pencil that never needed lead. So slow down, and take it easy. Chris is the former editor of Popular Woodworking Magazine.

He continues to blog and publish woodworking books at Lost Art Press. He's a hand-tool enthusiast though he uses power tools, too. Geez, you just aren't prepared at all, are you? That'll give you roughly the right angle, its close enough for this application. No, go ahead and use your hacksaw to cut off most of the waste, then use your file to bring it right up to the line. Take your time, you can take more off but you cant put it back.

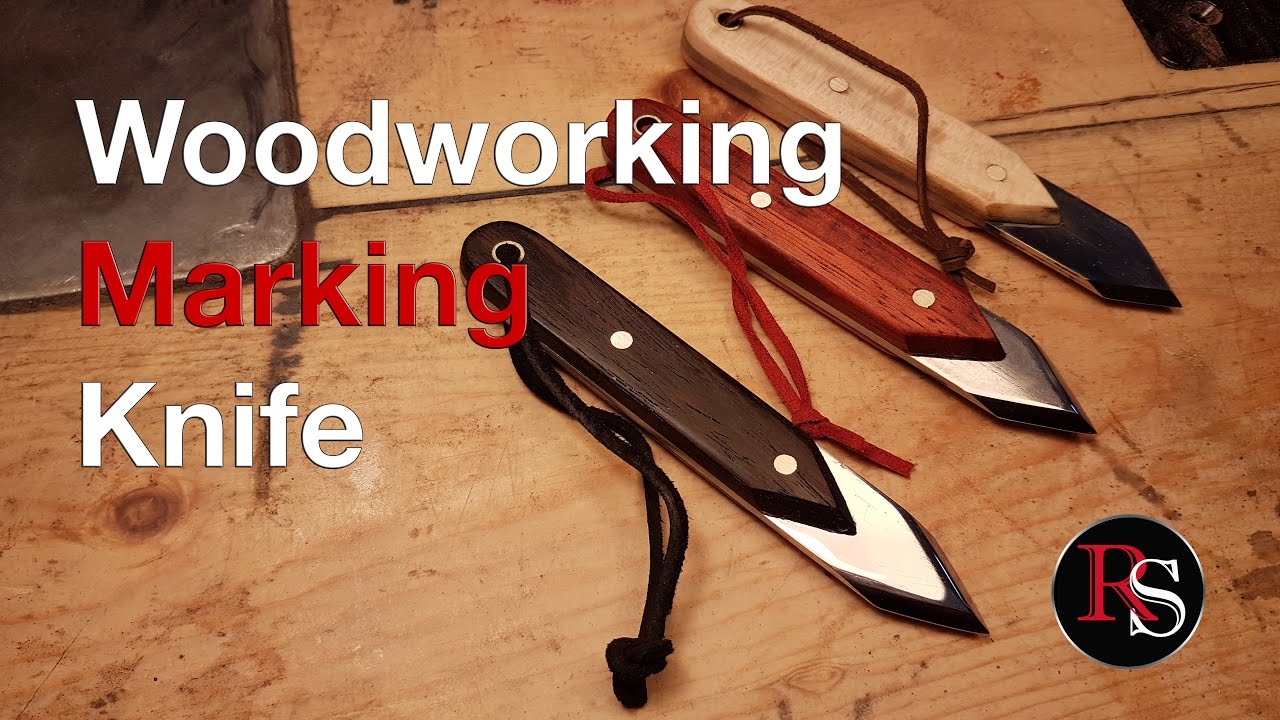

Consult the pictures to get an idea of the shape, if you don't already have one. Now you've got the rough profile of the blade down, so lets put in some bevels.

Since the angled edge, the one you just cut, is going to be the cutting edge, we'll be putting the bevel there. The angle were shooting for here is about 25 degrees. Once you've got that line draw, go ahead and use your file to remove the metal between that line and the edge, but don't go all the way down.

Leave about the thickness of a dime on the edge. It sounds a lot harder than it is, just take it slow and work to the lines. A word to the wise, the side of the blade you put the bevel on does matter. The knife shown is a right-hand bevel, meaning that when held the flat side of the blade will be on the left, and the bevel will be on the right. South paws should put the bevel on the other side. Now, i used my belt grinder for this, so it took me about a minute and a half, taking my time.

With a file, this shouldn't take more than 15 minutes. If you have one, a belt sander with a 60 grit belt will put in a decent bevel in less time, but I'm keeping my instructions simple. At any rate, once the bevels have been roughed in, meet me at the next step! Here's the easy step, drilling some holes for the pins that hold on the handle. First, youll want to draw a line down the center.

I coated mine in layout fluid, then used my calipers to scribe a line dead center, but a ruler and a steady hand with a sharpie works too. Now, on that center line, make a mark half an inch from the back of the blade the side opposite the cutting edge , then make a mark an inch and a half from the first one, then another mark an inch and a half from that. Check the pictures if that didn't make sense, it barely made sense to type it A drill press works best, but a handhel drill works fine too.

Heck, use a brace and bit if you want, itll give the same results, it just takes longer. This is the step that takes this from a lump of steel to being an actual knife. Forewarning though, this step involves extremely high heat and flammable substances. If you don't have the facilities to safely proceed, lack the necessary equipment or this just makes you nervous, don't do it. Instead, you can send out your knife to a commercial heat treatment service.

Tru Grit is a delight to work with, just download the packing slip, write down the steel type O1 and desired hardness 61HRC and ship it out, then join us at the next step.

Pretty simple process really. O1 is extremely easy to heat treat, use a blowtorch to heat the cutting edge to about f, which will make the steel glow cherry reddish in a dim room, and keep it there for about a minute. After that minute is up, dunk the blade in some warm oil, canola or peanut oil both work well. Hot tip, hold the blade in a set of pliers instead of by hand to avoid an ER visit! Now, after quenching, the steel is extremely hard, harder than glass and just as brittle.

It will shatter like glass if you drop it, so don't bloody drop it! Instead, wash off the oil and pop the blade into an oven preheated to f and let it bake for an hour. Take it out, let it cool, then send it back in for another hour.

Do this one more time. This is called tempering, and doing this will soften the steel and toughen it up, so you'll actually be able to use your knife without cracking it. Once you're done tempering, proceed to the next step!

A quick note, heat treating steel is an extremely complex process, and this is the bare minimum of information needed. If in doubt, consult the data sheets for your grade of steel, O1's can be found here. Alrighty, now that you've got your heat-treated blade, time to finish up the metal part of things.

First things first, you need to flatten the back the side opposite the bevel , so it sits nice against a straight-edge and Homemade Marking Knife Us makes a sharp edge.

To do this, stick a piece of sandpaper on a flat surface table saw top, kitchen counter, granite surface plate, piece of mdf , mark all over the blade with a sharpie and scrub it on the sandpaper until the sharpie disappears. Repeat with higher grits of sandpaper, up until you hit about grit. Flip the flade over, repeat with the top side to make it look nice. Nows also the time to fully finish the bevel. Use your file to bring it down almost to a sharp edge, then go back to the sandpaper to sharpen it.

If you've ever sharpened a chisel, its the same process. The key things here are to keep both the back of the blade and the bevel as flat as you can, and to polish both those surface as high as you can, so make for the best edge.

Its a lot easier to do these steps before you get the handle on, so get it right now and make your life easier later! Alrighty, now that the blades cleaned up, time to attach the handle scales! First, lets drill the pin holes in the handle material, which is hopefully oversize. First, stack the 2 piece of handle material on top of each other, then center the knife on the scales.

Drill a second hole, then stick in another pin in that hole. Doing this will allow you drill the third and final hole in exactly the right spot, so everything lines up right.

Once you've got all the holes drilled with the pins maintain alignment, trace around the knife, then cut off the excess material.

Once you have the front cut, you need to do some shaping. Round over the front, bevel it, do whatever yous like, then sand down the front.

You need to do this now, once the scales are attached you wont have access to the front of the scales. Now that the front of the scales are finished, time to glue them on.

Degrease the knife and the inside of the scales with some acetone or denatured alcohol, then mix up some 2 part epoxy. Apply the epoxy to the inside of the scales, then insert the pins. Use the pins to line up the scales properly on the blade, then clamp up the whole assembly and let the glue cure.

Once you've got the clamps on, be sure to clean any glue from the front of the scales before it dries, otherwise you'll scratch the blade trying to remove it. Once the epoxy is set, use a Homemade Marking Knife Journal ball peen hammer to peen over the pins, then shape the handle to fit.

I cant really tell you how to do this, just use files and sandpaper to shape the grip to be comfortable to hold. Once you've got the handle shaped and sanded, apply an appropriate finish. Again, cant tell you what to use for that without knowing what handle material your using. Taadaa, you're all finished up after sanding. In my case, i sanded the scales up to grit, then buffed with some white rouge. Since the wood has been stabilized, it takes a lovely polish and doesn't require a finish.

Hopefully this has inspired to you get to work making your own marking knife, its an extremely hand tool and a fun project. This style blade is also handy for loads of other tasks, its an excellent general-purpose utility knife.

Ive use mine for everthing from leather work to paper-craft, in addition to layout work. Like the style knife, but not up to making your own? Check out the listing for them at my Etsy shop , Homemade Marking Knife Yamaha where i sell both the completed blades, as well as just the knife portion if you feel like making your own handle.

Heat the blade till the magnet does not stick. I didn't even know what a marking knife was, but I have been dissatisfied with pencil marking for a long time, so your instructable has inspired me to make one. Reply 4 years ago.

|

Drafting Table Hinges Hardware Optimization Cabinet Router Bit Number Telus Login For Router Dayton 6x9 Belt And Disc Sander White |

DUBLYOR

05.01.2021 at 19:12:34

BaTyA

05.01.2021 at 23:43:15