Delta Radial Arm Saw Rs 830 Install,Finish Carpenter Tool Vest 10,Soft Close Drawer Slides How Does It Work Error,Kreg Pocket Hole Jig Drill Bit Size Guide - Downloads 2021

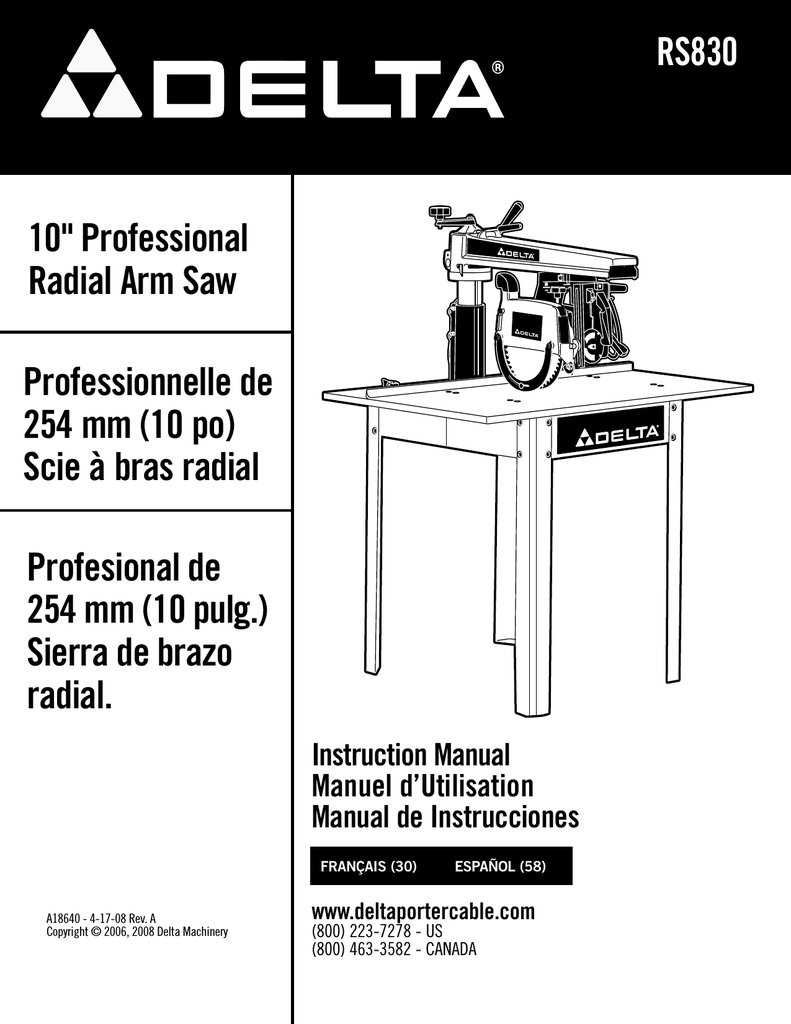

Also See for Instruction manual - 29 pages Instruction manual - 32 pages. Table Of Contents. Quick Links. Table of Contents. Radial Arm Saw. Previous Page. Next Page. Delta Instruction Manual 29 pages. Delta 12" single-bevel compound delta radial arm saw rs-830 install saw instruction's manual 18 pages. Delta 12" compound laser miter saw instruction manual 25 pages. Saw Delta Instruction Manual 10" professional table saw 32 pages. Contact us online at www. Page 4 volts and the rated current of the saw.

Either use a qualified electrician to do the conversion, or take the machine to an Authorized Delta Service Center. The machine must conform to the National Electric Code and all local codes and ordinances. All visitors should be kept at a safe distance from work area. Your shop is a potentially dangerous environment. Delta radial arm saw rs-830 install unauthorized start-up of a machine by a child or visitor may result in injury.

Everyday eyeglasses are NOT safety glasses. Also use face or dust mask if cutting operation is dusty. Remove the protective coating from all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene do Delta Radial Arm Saw Rs 830 Use not use acetone, gasoline or lacquer thinner for this purpose.

While the machine is suspended, attach the legs to each corner see inset of the base. Page 10 5. Tighten the track arm clamp lever C Fig. Remove the blade guard clamping rod and washer G Fig. Remove blade guard assembly H. Attach the bracket A to the bottom of the right side of the saw base Fig.

Page 12 3. Place the wrench F Fig. Tighten the arbor nut E. Make certain that the wrench F is above the table surface. If necessary, raise the track arm. Page 13 7. To adjust, remove the screw R Fig. Loosen the locknut S and turn the leveling screw T to raise or lower table mounting bracket N.

After adjustment, tighten the locknut S and replace the screw R. Check and adjust the other table mounting bracket in the same manner. Place the main table board A Fig. Fit the the two roll delta radial arm saw rs-830 install in the table mounting brackets into the two holes in the bottom of the main table board A. Page Operation Be sure your power supply agrees with the nameplate marking. AC Only means that your saw will operate on alternating current only. A voltage decrease of 10 percent or more will cause a loss of power and overheating.

If this tool does not operate, check the power supply. Doing otherwise may cause damage to the saw or personal injury. Page 17 To reduce the risk of injury, turn unit off and delta radial arm saw rs-830 install machine from power source before installing and removing accessories, before adjusting or changing set-ups, or when making repairs. An accidental start-up can cause injury. Before connecting the radial arm saw to the power source or operating the saw, always inspect the guard and splitter for proper operation alignment and clearance with saw blade.

The ball bearings must ride smoothly and evenly against the track rods to do accurate work. Page 19 1. Remove the blade guard and place the cuttinghead in a cross-cut position Fig. Place a square A Fig. Make certain the square is between the teeth of the saw blade. The track arm should be unlocked when the handle is in the rear position, resting on the stop C. To adjust the track-arm handle: Disconnect the machine from the power source! Page 21 5. Loosen the three screws F Fig.

To move the front of the track arm to the right, loosen the set screw H Fig. To move the front end of track arm to the left, loosen the set screw J and tighten the set Fig. Page 22 3. To adjust, loosen the yoke-clamping handle and the two screws C Fig. Swivel the yoke D until the saw blade is parallel with the square. Tighten the yoke-clamping handle and the two screws C Fig.

Disconnect the machine from the power source! Remove the blade and blade guard assembly. Move the motor so that the arbor is in the down position Fig. Place the delta radial arm saw rs-830 install A Fig.

Page 24 Fig. Clamp the fence Make sure that the saw blade is to the left and behind the fence. Page 25 Keep the saw blade guard, delta radial arm saw rs-830 install, and anti-kickback teeth in place and operating properly.

Keep teeth sharp. If teeth are not operational, return your unit to the nearest authorized Delta service center for repair. The splitter must be in alignment with the saw blade and the teeth must stop a kickback once it has start.

Check their action before ripping by pushing the wood under the anti-kickback teeth. Make a push-stick from plywood or softwood, equal to or less than the width of the workpiece. All plastic parts should be cleaned with a soft damp cloth. Page Service Two Year Limited New Product Warranty Delta will repair or replace, at delta radial arm saw rs-830 install expense and at its option, any new Delta machine, machine part, or machine accessory which in normal use has proven to be defective in workmanship or material, provided that the customer returns the product prepaid to a Delta factory service center or authorized service station with proof of purchase of the product within two years and provides Delta with reasonable opportunity to verify the alleged defect by inspection.

Page 32 5. Maintenir la position en ramenant le levier de fixation du bras sur rail C fig. Au besoin, relever le bras sur rail. Fixer la table en position. Page 42 Retirer la vis, la rondelle plate et la cale G fig. Page 48 Desserrer les trois vis F fig. Page 51 Fig. Fixer le guide. Page 52 Garder des dents tranchants. Canada: Page 58 voltios y la corriente nominal de la sierra. Su taller es un lugar potencialmente delta radial arm saw rs-830 install. Also use face or dust mask if cut- ting operatLos anteojos de uso diario NO son lentes de seguridad.

Page 61 Mantenga los dientes afilados. El hendedor debe estar alineado con la hoja y los dientes deben detener un retroceso una vez que ha comenzado. Retire la arandela y la barra de ajuste del protector de la hoja G Fig.

Retire el conjunto del protector de la hoja H. Page 66 Coloque la llave Delta radial arm saw rs-830 install Fig. Ajuste la tuerca del eje E. Page 67 Para ajustar, retire el tornillo R Fig. Afloje la tuerca de seguridad S y gire el tornillo nivelador T para levantar o bajar el soporte de montaje del banco N.

Coloque las dos clavijas giratorias de los soportes de montaje del banco dentro de los dos orificios que se encuentran en la parte inferior de la tabla de banco principal A.

|

Diy Burnt Wood Countertops Computerized Wood Cutter 42 |

LEDY_VUSAL_17

04.09.2020 at 11:59:11

UREY

04.09.2020 at 18:57:48

JanimKa

04.09.2020 at 23:20:41

kaltoq

04.09.2020 at 17:46:10

AVTOSHKA

04.09.2020 at 14:39:27