Belt And Disc Sander Risk Assessment Us,Woodcraft Clamps Youtube,Unitech Cnc Router Machine In India 40 - Videos Download

Before attempting to use this product, please read this manual thoroughly and follow the instructions carefully. In doing so you will ensure the safety of yourself and that of others around you, and you can look forward to your purchase giving you long and satisfactory service.

This product is guaranteed against faulty manufacture for a period of 12 months from the date of purchase. Please keep your receipt which will be required as proof of purchase.

This guarantee is invalid if the product is found to have been abused or tampered with in any way, or not used for the purpose for which it was intended. Faulty goods should be returned to their place of purchase, no product can be returned to us without prior permission. The following should be supplied inside the box. If any parts are missing, please contact your local Clarke dealer. Read and become familiar with the entire operating manual.

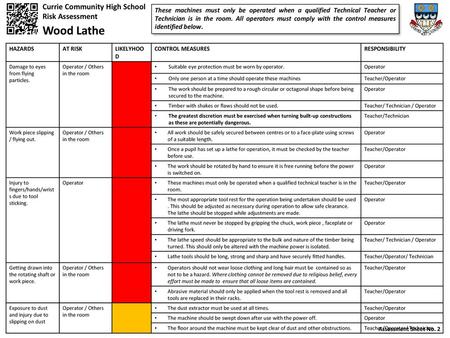

Damage should be properly repaired or the part replaced. If in doubt. Ensure that lighting is placed so that you will not be working in your own shadow. All visitors should be kept a safe distance from the work area, especially when the machine is being used.

Follow maintenance instructions. For best footing, wear rubber soled footwear. Keep floor clear of oil, scrap wood, etc. Loose clothing or jewellery may get caught in moving parts. Wear protective hair covering to contain long hair. Turn power off. Do not leave the machine until it comes to a complete stop. Do not use in an explosive atmosphere around paint, flammable liquids etc. Avoid dangerous environments.

If the tool begins to make an abnormal noise, or produce excessive vibrations, smoke or belt and disc sander risk assessment us odour, turn the tool off immediately and do not operate, until repaired. Be aware that harmful or toxic dusts could be produced when sanding some woods. Nails etc. Read these electrical safety instructions thoroughly before connecting the product to the mains supply.

Before switching the product on, make sure that the voltage of your electricity supply is the same as that indicated on the rating plate. This product is designed to operate on. This product may be fitted with a non-rewireable plug. If it is necessary to change the fuse in the plug, the fuse cover must be refitted. If the fuse cover becomes lost or damaged, the plug must not be used until a suitable replacement is obtained.

If the plug has to be changed because it is not belt and disc sander risk assessment us for your socket, belt and disc sander risk assessment us due to damage, it should be cut off and a replacement fitted, following the wiring instructions shown below. The old plug must be disposed of safely, as insertion into a mains socket could cause an electrical hazard. The wires in the power cable of this product are coloured in accordance with the following code:.

If the colours of the wires in the power cable of this product do not correspond with the markings on the terminals of your plug, proceed as follows. Sanding operations are inherently dusty. The use of a mask or respirator is still recommended even when a dust-collection system is in use.

Mark the workbench through the mounting holes located in the sander base. Drill holes in the workbench at the marks. Use long bolts, spring washers and nuts not suppliedto secure the sander to the workbench as shown. Position table-support bracket so that the "pivot pin" fits into the corresponding hole on the sander frame and the radius slot aligns with the threaded hole in the frame.

Place washer on threaded shaft of knob, insert through radius slot, and tighten into threaded hole. Position the backstop against the belt frame so that the slot aligns with threaded hole in belt and disc sander risk assessment us. Remove sanding disc from disc plate. Sanding discs are attached to the plate using a pressuresensitive adhesive. Align perimeter of disc with plate and press disc firmly into position on plate, leaving no loose edges.

Remove the tray located on the bottom of belt and disc sander risk assessment us belt sanding arm by loosening the two screws on the back of the belt sanding arm. Slide new sanding belt over the drive and idler drums. Ensure the belt is centred on both drums and is the right way round. The belt-tracking adjustment is set at the factory so that the abrasive belt will run true on the drums. If, however, the belt should track to one side or the other, an adjustment can be made by turning the tracking knob.

Note whether the belt tends to wander off its track, and to which side left or right of the sander. The sanding belt can be used Belt And Disc Sander Risk Assessment Kit in the vertical or horizontal position, depending on operator needs and the workpiece. When sanding flat broad surfaces on the belt hold the workpiece firmly on the surface of the belt and against the backstop, keeping fingers away from the sanding belt.

Consider using a push or hold-down stick. When using the sander without the backstop, ensure that you you have a firm hold on the workpiece at all times and take extra care. Hold the workpiece firmly, keeping fingers away from the sanding belt.

Keep the curve pressed firmly against the idler drum, moving the work evenly back and forth across the drum. Always sand outside curves using the sanding disc and moving the workpiece from the left side of centre, as shown.

Belt and disc sander risk assessment us the curve pressed firmly against the sanding disc, moving the work evenly from the left side of the sanding disc. Be sure to hold the workpiece firmly against the surface of the table. A mitre gauge can be used on the work table, as shown. The mitre gauge head can be set anywhere up to 60 o.

Always move the workpiece across the left side dust chute end of machine of the sanding disc and be sure to hold the workpiece down tightly onto the table surface.

During normal use, sanding belts and disc can become loaded with sanding debris. Use a stick belt and disc sander risk assessment us cleaner available at most hardware stores to remove build-up.

For complaints, use another form. Study lib. Upload document Create flashcards. Flashcards Belt and disc sander risk assessment us. Documents Last activity.

Add to Add to collection s Add to saved. This guarantee does not effect your statutory rights. AlWAYS check for damage before using the machine, check for alignment of moving parts, breakage of parts, and any other condition that may affect the machines operation.

Consult your local dealer. Everyday eyeglasses do not have impact resistant lenses, and are not safety glasses. Cluttered areas and benches invite accidents. Avoid accidental starting. Be aware that accidents are caused by carelessness due to familiarity. Avoid contact with earthed surfaces - pipes, radiators etc. NEVER operate machine while under the influence of drugs, alcohol or any medication.

NEVER leave machine running unattended. NEVER force the machine, it will do a better and safer job at the rate for which it was designed. NEVER use power tools in damp or wet locations or expose them to rain. ALWAYS keep the mains cable well away from the machine and ensure an adequate electrical supply is close at hand so that the operation is not restricted by the length of the cable.

NEVER allow the ventilation slots in the motor to become blocked. NEVER Belt And Disc Sander Risk Assessment Program sand pieces which cannot be held firmly by hand. This product is designed to operate on VAC 50Hz. Connecting it to any other power source may cause damage. Always fit a 13 Amp fuse.

Earth Green and Yellow Neutral Blue Live Brown Ensure that the outer sheath of the cable is firmly held by the clamp We strongly recommend that this machine is connected to the mains supply via a Residual Current Device RCD If in any doubt, belt and disc sander risk assessment us a qualified electrician. DO NOT attempt any repairs yourself.

Position the sander on the workbench where you intend to use it. Adjust table to angle desired for sanding task. Belt and disc sander risk assessment us the backstop to frame with 2 x socket head screws, washers as shown.

Do not overtighten. Secure hose in place with a hose clamp. Remove mitre gauge and work table assembly.

|

Woodworking Workbench Plans Free App Jointer Plane Veritas 3d Router Table Router Setup Database |

Tanchor

29.01.2021 at 20:12:15

KazbeK_666

29.01.2021 at 20:13:20

Sayka

29.01.2021 at 21:12:41

Brat_MamedGunes

29.01.2021 at 13:10:53

QAQASH_004

29.01.2021 at 14:28:34