Beam Compass Vs Trammel,Rotary Wood Carving Accessories Nz,Wood Miter Saw Laser 90,Woodworking Plans Drawer 2020 - Try Out

The top of the case is imprinted with a rectangle that has a fleur-de-lis at each corner. Carolyn H. Edwards of Glen Echo, Md. The marks on this compass are similar to those used by Kern between and AG Aarau? ID Number MA. Beam Compass Description This instrument consists of a wooden beam and a single German silver trammel with a micrometer and needle point. A large round hole in one end of the beam allows the instrument to be hung.

The other end of the beam is marked in pencil at each of the first six inch points. This instrument was owned by the renowned American designer of steam engines, Erasmus Darwin Leavitt Jr. Chicago, , Location Currently not on view date made ca ID Number Two trammels have thumbscrews for fastening to a wooden bar not included and for attaching one of the five points.

Above this mark is scratched: CE1RD. Compare this mark to The attachments include a pencil point, an adjustable pen point, two steel needle points, and one brass needle point. A rectangular wooden case is covered with morocco leather and lined with green velvet. By the points were stainless steel instead of steel. New York, , , ID Number Beam Compass Description This German silver instrument has steel points.

The two trammels, or frames for the pencil and needle points, have thumbscrews on their fronts. These thumbscrews are ridged around the edge and have a circular pattern on their tops. The number 19 is engraved inside each trammel. Smaller thumbscrews attach holders for needle and pencil points.

These holders have horizontal scrolling but are not identical to each other. Another thumbscrew allows the needle point to be reversed. A micrometer adjustment is below one of the trammels.

A separate adjustable pen point appears to belong to a regular drawing compass, rather than to this beam compass, because it is longer than the other holders and shaped differently. Compare this piece to MA. No bar for connecting the trammels was received with the instrument. These beam compasses are also similar but not identical to each other.

Although this beam compass could not be identified, it probably was made in Germany and dates to the first decade of the 20th century, like the advertised instruments. Leslie Leland Locke — earned bachelor's and master's degrees from Grove City College.

He was interested in the Peruvian quipu. He donated his collection of early calculating machines to the Smithsonian and his early American textbooks to the University of Michigan. Chicago, , ; Louis C. Karpinski, "Leslie Leland Locke," Science n. Location Currently not on view date made early 20th century ID Number Beam Compass Sold by Dietzgen Description This German silver instrument has two trammels, one with a reversible needle point and micrometer, and one with a holder for a pencil lead.

The shank is graduated into 16 units and each unit is further divided into increments of one quarter. One end of the shank has a fixed cutter wheel that scores a fine line in the drywall. From Wikipedia, the free encyclopedia. This article needs additional citations for verification. Please help improve this article by adding citations to reliable sources. Unsourced material may be challenged and removed. James and John Knapton, et al. Measuring and alignment tools.

Categories : Metalworking hand tools Woodworking hand tools. Hidden categories: Wikipedia articles incorporating a citation from the Cyclopaedia Wikipedia articles incorporating text from Cyclopaedia Articles needing additional references from April All articles needing additional references.

Namespaces Article Talk. Views Read Edit View history. Help Learn to edit Community portal Recent changes Upload file. Download as PDF Printable version. Deutsch Edit links. Look up beam compass in Wiktionary, the free dictionary. A final coat of shellac is applied, then steel wool with a good quality wax applied and buffed out.

This is the finish of choice for many of my projects since it is durable and easily repaired if needed. The tool pathing was virtually perfect as it has been for the 13 years I have been using Vectric software.

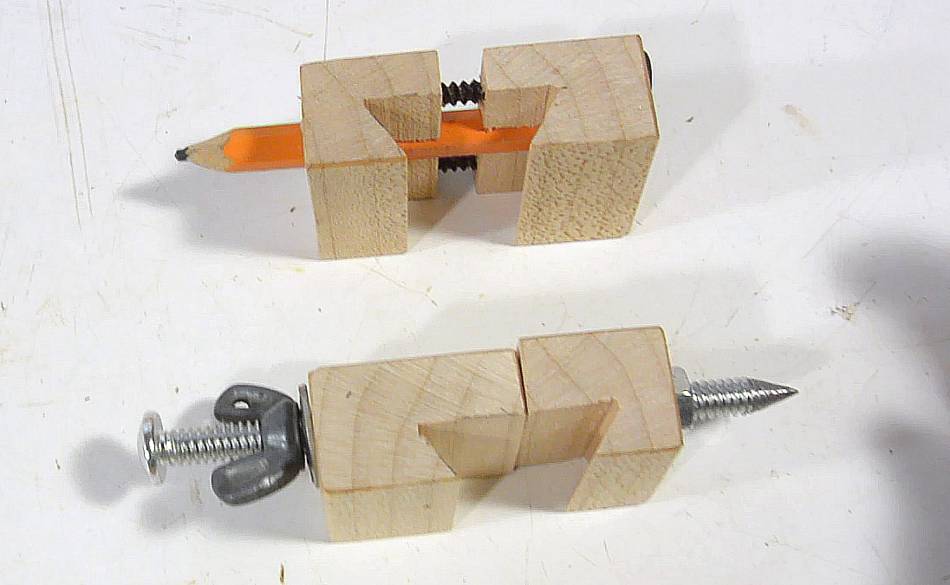

Any changes I might make are primarily design changes, there is nothing like having an item in hand to decide what I do not like about it. We then asked Ted if he has any tips or advice to fellow makers…. The key to successful woodworking projects has always been starting with straight, square, and flat stock. Using a CNC does not change that axiom. Pockets can be cut in the wooden jaw inserts to hold small parts securely and positively locate them.

I use a pair of vices so that I can clamp longer pieces like the top of this box easily and work right up to the edges with no clamp interference. If a special fixture is required, build it.

In the long run, it will save time and prevent frustration. An example of this is milling the hinge pockets in the box. I secured a piece of 2X4 pine to the spoil board then milled the vertical faces parallel to each other with a known distance between the faces.

After then it was a simple matter to clamp the box halves to the rail and machine the hinge pockets and pre-drill the screw holes. Before we let him go, we asked Ted what plans he had for the future…. I have just built a new 4th axis for my machine to replace the one I had cobbled together years ago. I am revisiting making segmented turnings on that axis with the goal to be able to do the inside without using a lathe for the inside cavity.

The slicing ability of Aspire will figure prominently in this strategy. We wanted to say a huge thank you to Ted for taking the time to talk to us about his project so that we could inspire our community to try something new.

If you have a story you would like us to feature, please get in touch, simply email online vectric. We would love to hear from you.

We wanted to hear more about why he decided to create the beam compass… The project started out with a need I had for a good beam compass. After coming up with the idea and the materials Ted then went to work planning and designing the project to then cut the beam compass… Design began by researching how other shop-built beam compasses have been built.

Ted explained about the finishing and building of the project with some reflection… When I build boxes I usually finish sand the parts before assembly to avoid rounding edges.

|

Desk Drawer Hardware 31 Best Rap Tiny Desk Concerts Limited General Finishes Gel Stain Gray On Oak |

AVTOSHKA

02.03.2021 at 20:34:12

KRASOTKA

02.03.2021 at 16:56:43

VIDOK

02.03.2021 at 19:49:11

Raufxacmazli

02.03.2021 at 11:36:45